+86-15995701933

+86-15995701933 [email protected]

[email protected]- OEM Plastic Mould Manufacturers

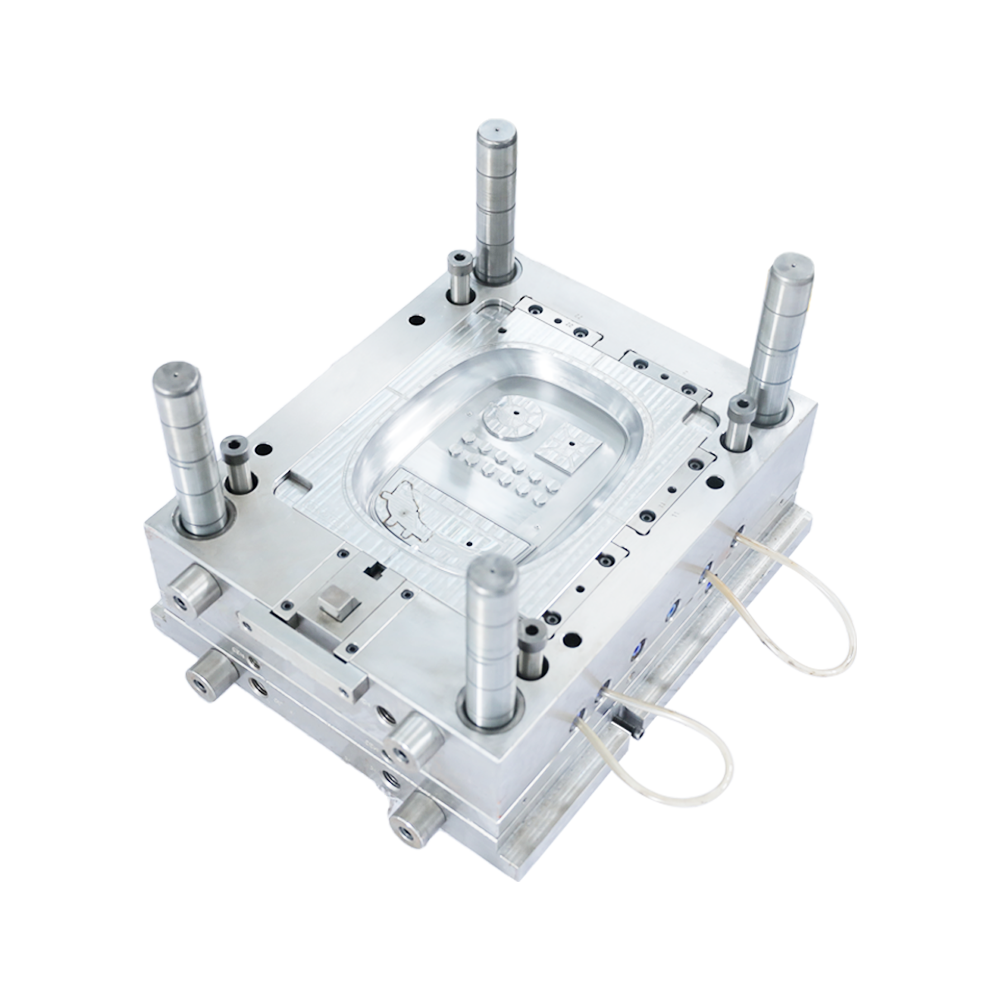

Injection molding is a process that allows plastics to be molded with metal or ceramic inserts. These metal or ceramic inserts are placed in a mold and then melted plastic is injected to create a seamless piece. This type of molding is ideal for automotive applications because it reduces weight and utilizes metal to reduce operational costs. It is important to select the right mold for your needsm The type of steel you use will also determine the cost of the mold.

| Whether to customize: | Yes |

| Mold accuracy: | ±10μm |

| Mold life: | 300,000~500,000 mold times |

Suzhou Huihong Electric Co., Ltd. is a professional manufacturer of precision molds, injection molding, assembling and silk-printing. Injection parts automotive Suppliers. Some moulds are exported to Japan, Europe and the United States. We have the right to import and export the goods. As Custom Injection parts automotive Maker, We can develop and manufacture the moulds according to the needs of our customers. We pay attention to quality control, new project development, personnel training, team spirit. In recent years, we have established long-term business relationships with many well-known enterprises at home and abroad.

5 years of experience in bath bar moulding

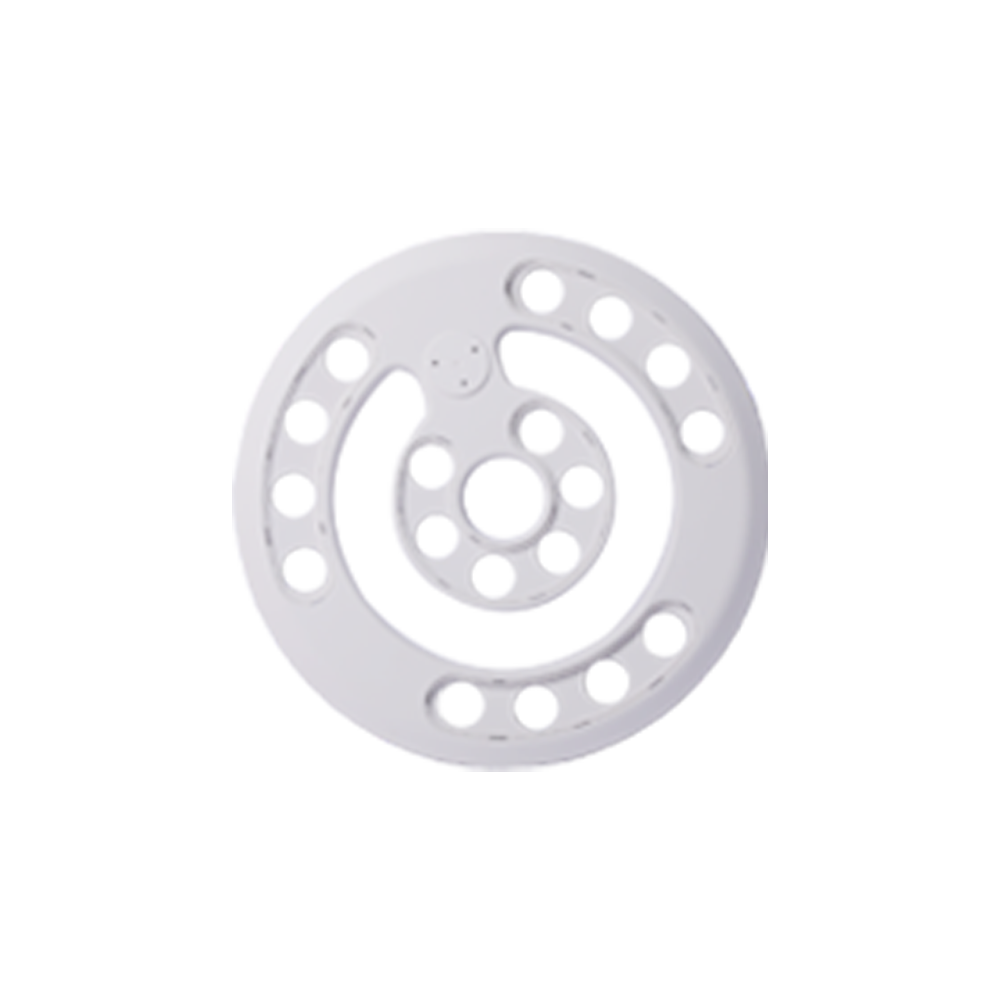

20 years of experience in mold making for vacuum cleaner

15 years of experience in mold making for power tools

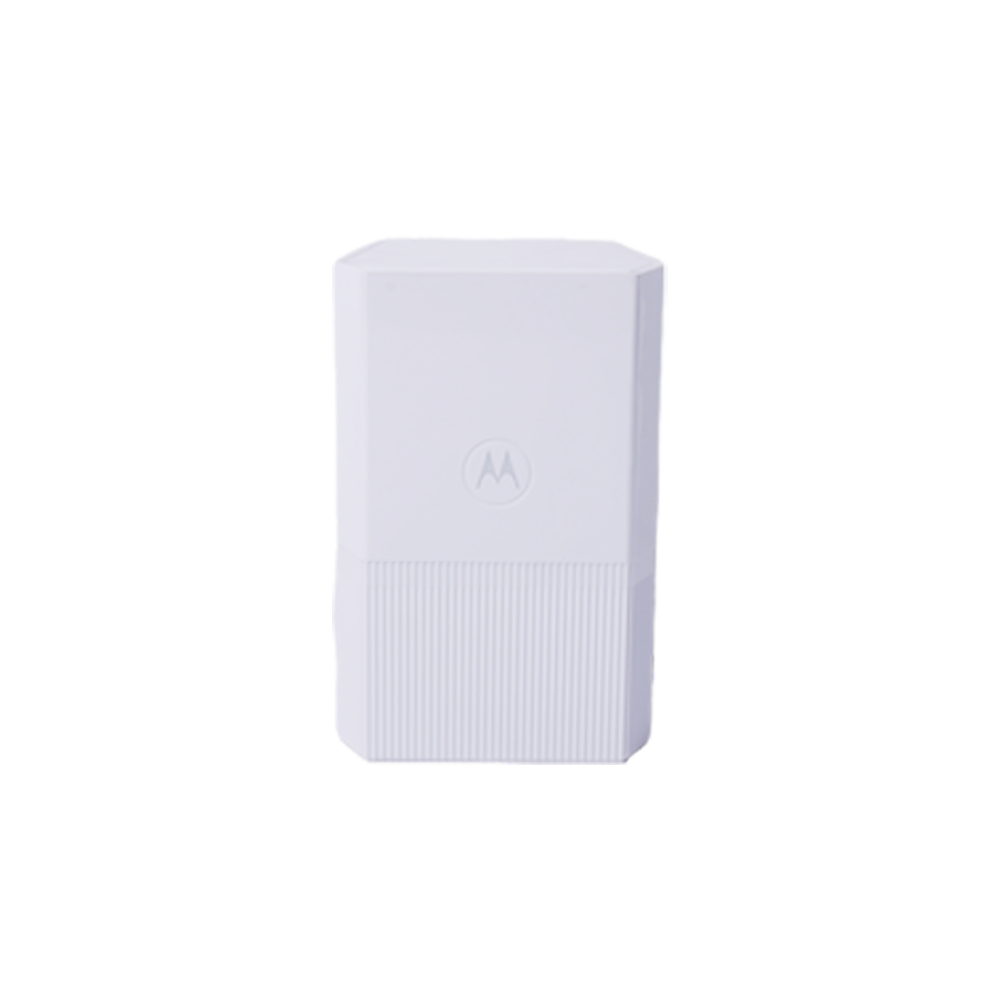

10 years of experience in router mold making

10 years of experience in mold making for coffee machine

Charger top cover mold

Bathroom parts circuit board cover mold

Router front cover mold

Surgical lamp front cover mould

Inverter housing mould

Router back shell mold

Infrared transceiver cover shell mold

Vacuum cleaner front cover mould

Colorimeter

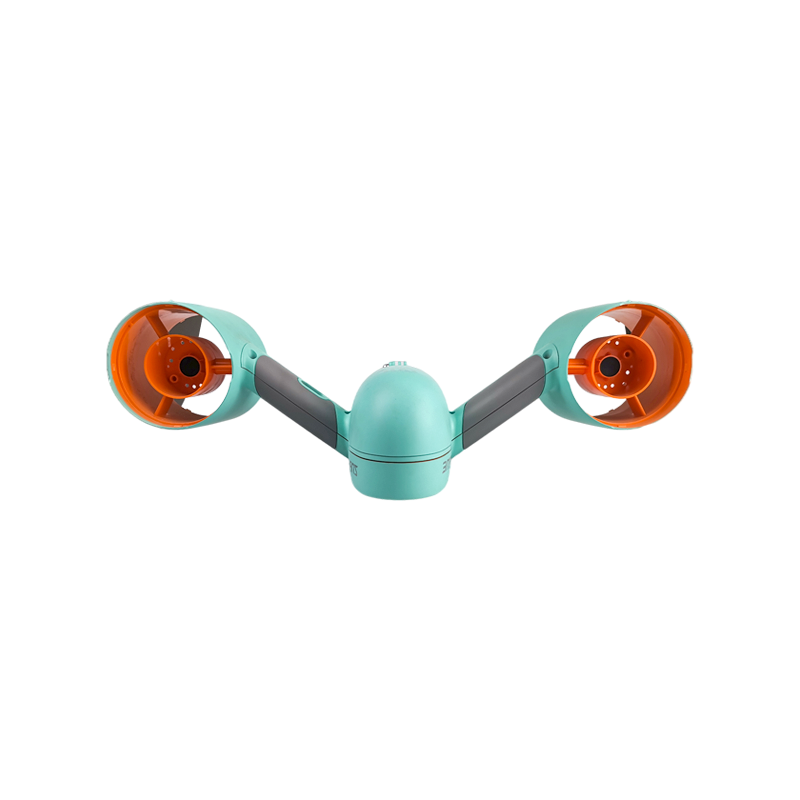

Underwater drone body mold

Nail gun shell mould

Injection parts automotive