+86-15995701933

+86-15995701933 [email protected]

[email protected]- OEM Plastic Mould Manufacturers

The vacuum cleaner is mainly composed of three parts: dust collection, dust collection, and dust filter. Generally, it includes a series-excited commutator motor, a centrifugal fan, a dust filter (bag) and a dust collection accessory. The power of general vacuum cleaners is 400-1000W or higher, and the power of portable vacuum cleaners is generally 250W and below. The vacuum cleaner can remove dust, mainly because its "head" is equipped with an electric exhaust fan. There is a wind impeller on the rotating shaft of the exhaust fan. After the power is turned on, the exhaust fan will generate high suction and pressure at a speed of 500 revolutions per second. The air in the fan is replenished, causing an instantaneous vacuum inside the vacuum cleaner to form a negative pressure difference with the outside atmospheric pressure. Under the action of this pressure difference, the dust-containing air is inhaled. Dust and other sundries enter the dust filter bag in turn through the carpet or floor brush, long connecting pipe, elbow, hose, and hose joint.

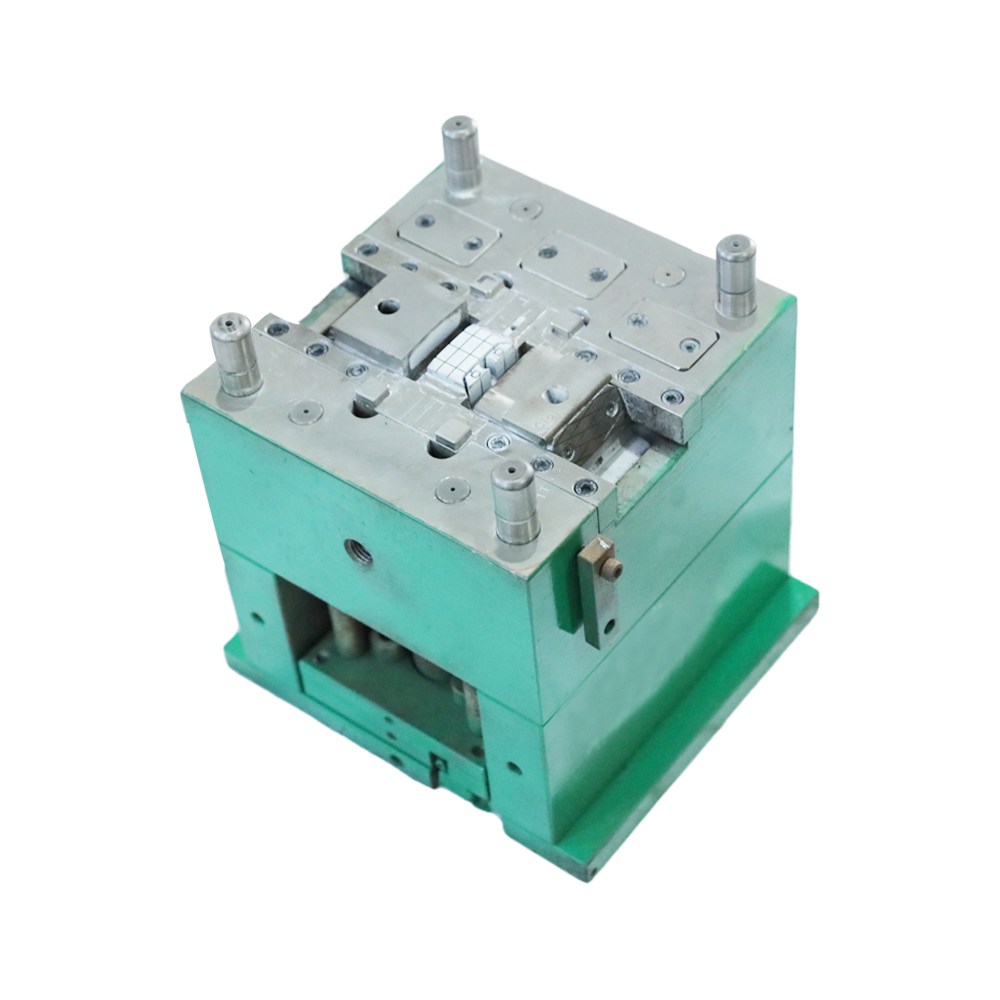

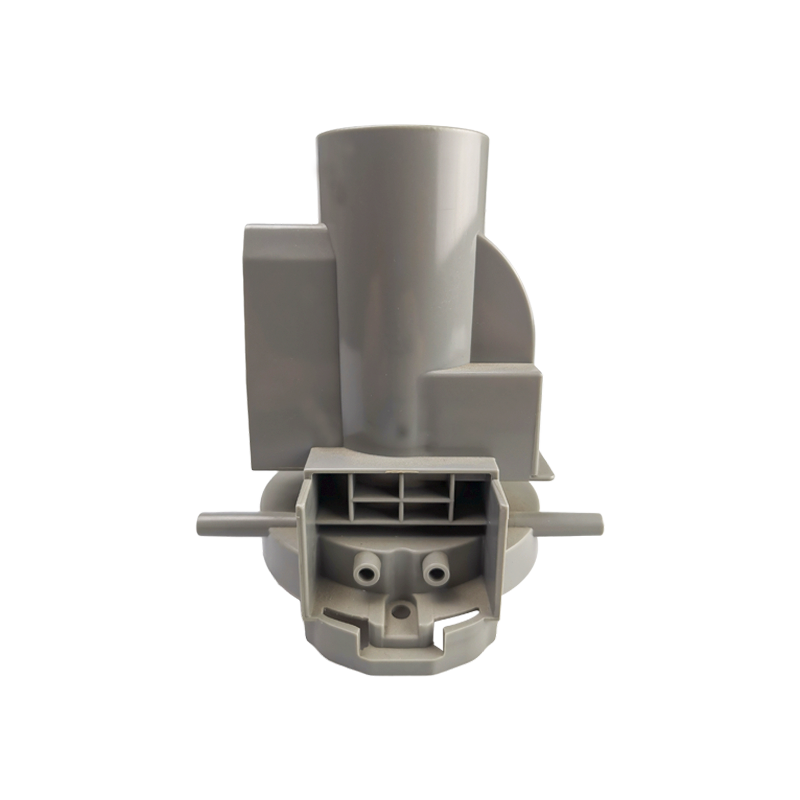

| Mold Name | Vacuum cleaner front cover mould |

| Product Material | ABS GP22 |

| Mold Steel for cavity | NAK80 |

| Mold Steel For Core | 2738H |

| Steel For Base | S50C |

| Mold Estimated Size | 600X550X636mm |

| Mold Weight | 1200kg |

| Press Machine Size | 470T |

| MOQ | 1 Set |

| Trade Terms | FOB |

| Payment Terms | 50% prepayment before design making, 50% payment after final sample is confirmed. |

Suzhou Huihong Electric Co., Ltd. is a professional manufacturer of precision molds, injection molding, assembling and silk-printing. Vacuum cleaner front cover mould Suppliers. Some moulds are exported to Japan, Europe and the United States. We have the right to import and export the goods. As Custom Vacuum cleaner front cover mould Maker, We can develop and manufacture the moulds according to the needs of our customers. We pay attention to quality control, new project development, personnel training, team spirit. In recent years, we have established long-term business relationships with many well-known enterprises at home and abroad.

5 years of experience in bath bar moulding

20 years of experience in mold making for vacuum cleaner

15 years of experience in mold making for power tools

10 years of experience in router mold making

10 years of experience in mold making for coffee machine

Bathroom parts circuit board cover mold

Cell phone holder lower clamping mold

Surgical lamp front cover mould

Nespresso coffee chiller back cover mold

Socket top shell mold

Hand drill gun shell mold

Router back shell mold

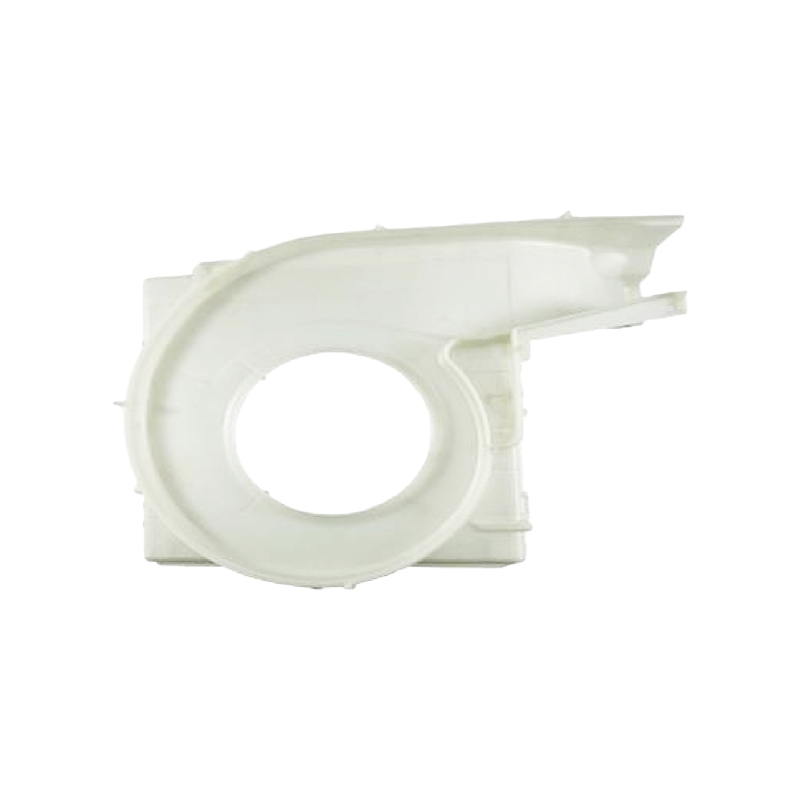

Vacuum cleaner front cover mould

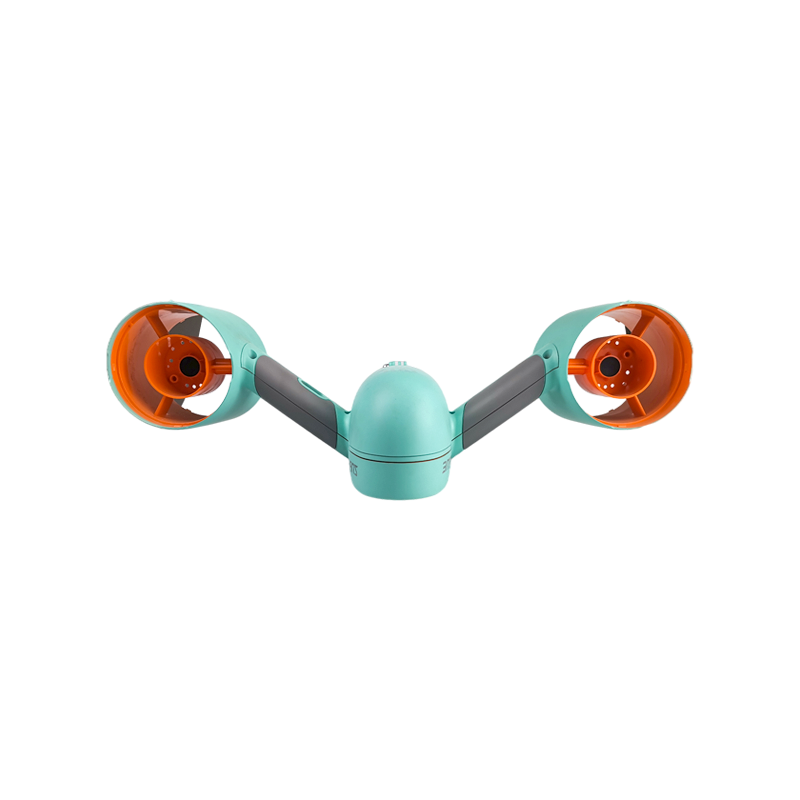

Underwater drone body mold

Auto air conditioner snail shell mold

Auto control panel mould

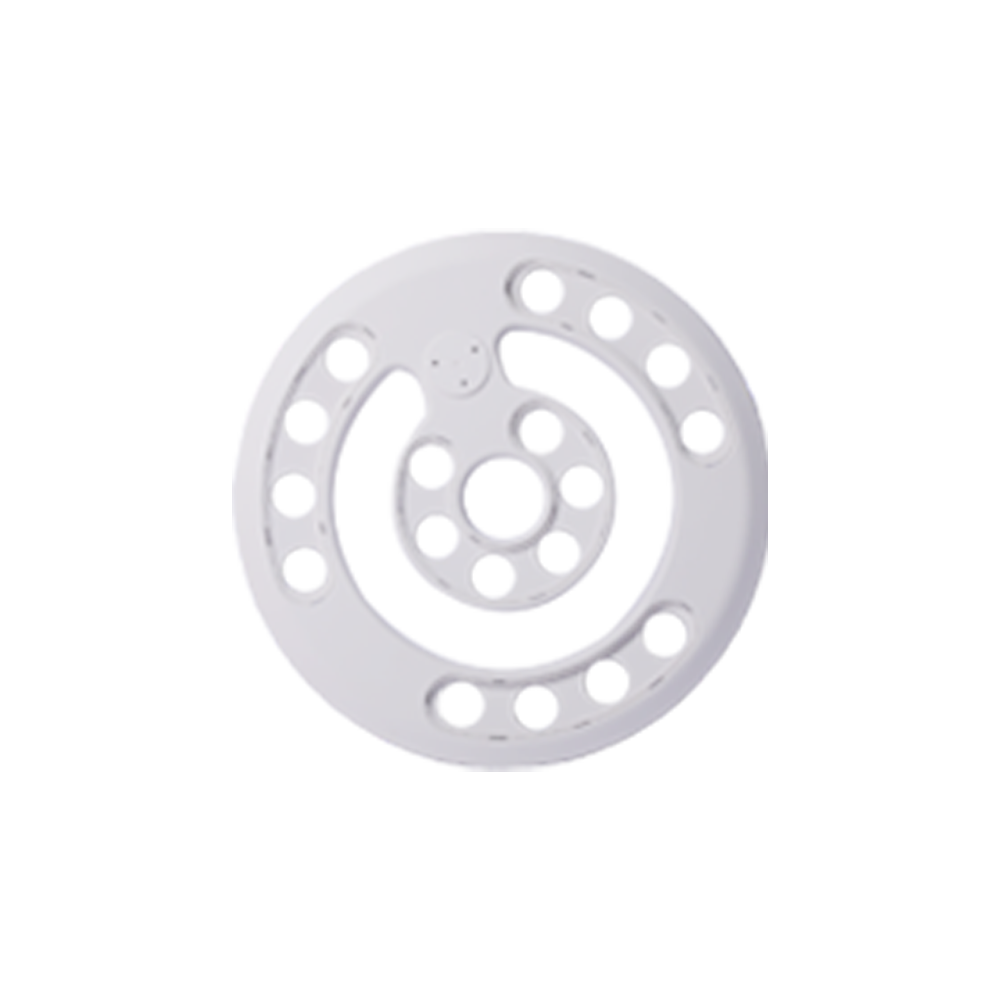

Vacuum cleaner interface mold