+86-15995701933

+86-15995701933 [email protected]

[email protected]- OEM Plastic Mould Manufacturers

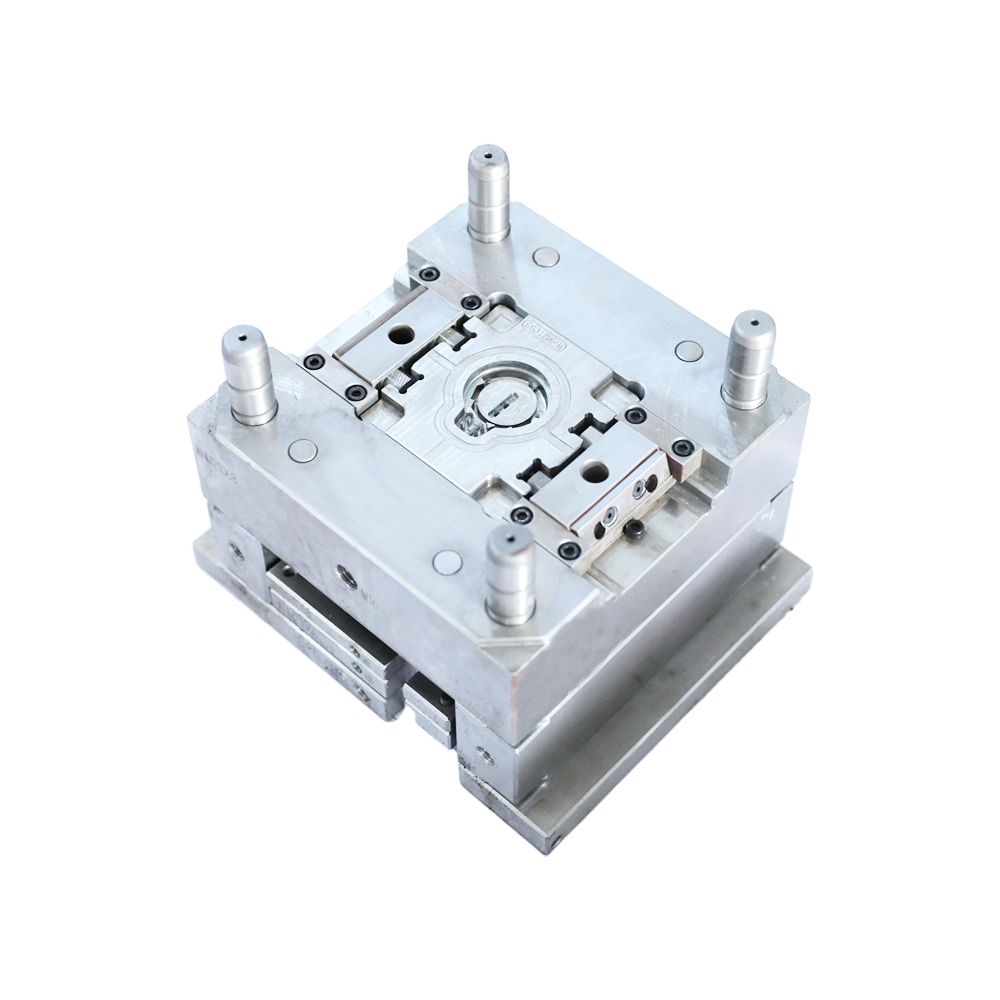

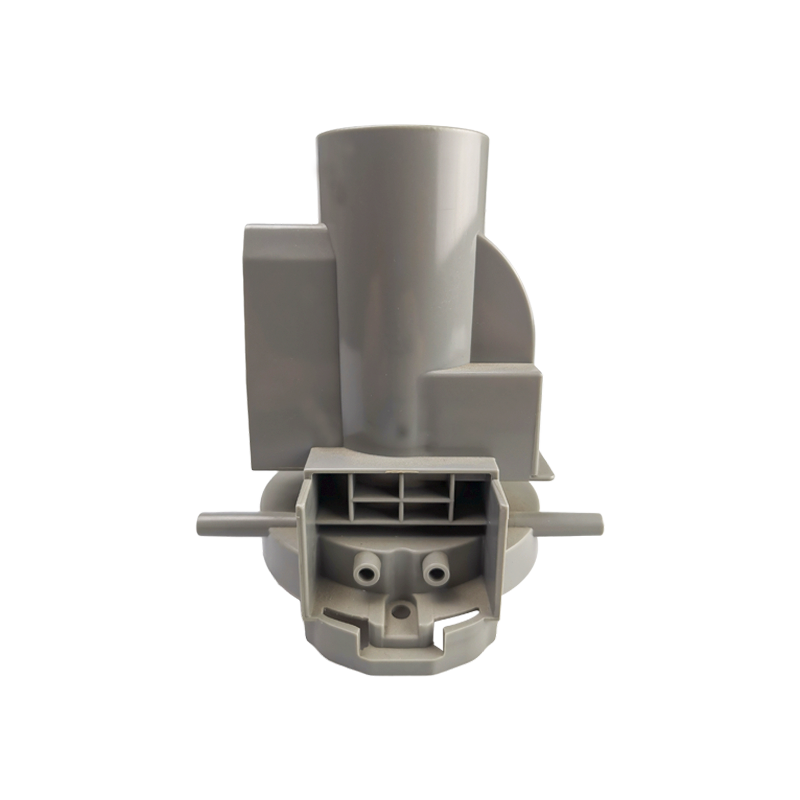

The socket top shell mold is a popular choice for high-end casting jobs. The process begins with heating the mold pattern to a certain temperature and coating it with a lubricant. The pattern is then clamped inside a dump box containing a mixture of sand and resin binder. The melted mixture partially cures and forms a shell around the pattern. The mold is then cured in an oven, ejecting the cured shell from the pattern.

| Mold Name | Socket upper shell mold |

| Product Material | PC+ABS (V0) |

| Mold Steel for cavity | S136 |

| Mold Steel For Core | S136 |

| Steel For Base | S50C |

| Mold Estimated Size | 350*300*390mm |

| Mold Weight | 290kg |

| Press Machine Size | 250T |

| MOQ | 1 Set |

| Trade Terms | FOB |

| Payment Terms | 50% prepayment before design making, 50% payment after final sample is confirmed. |

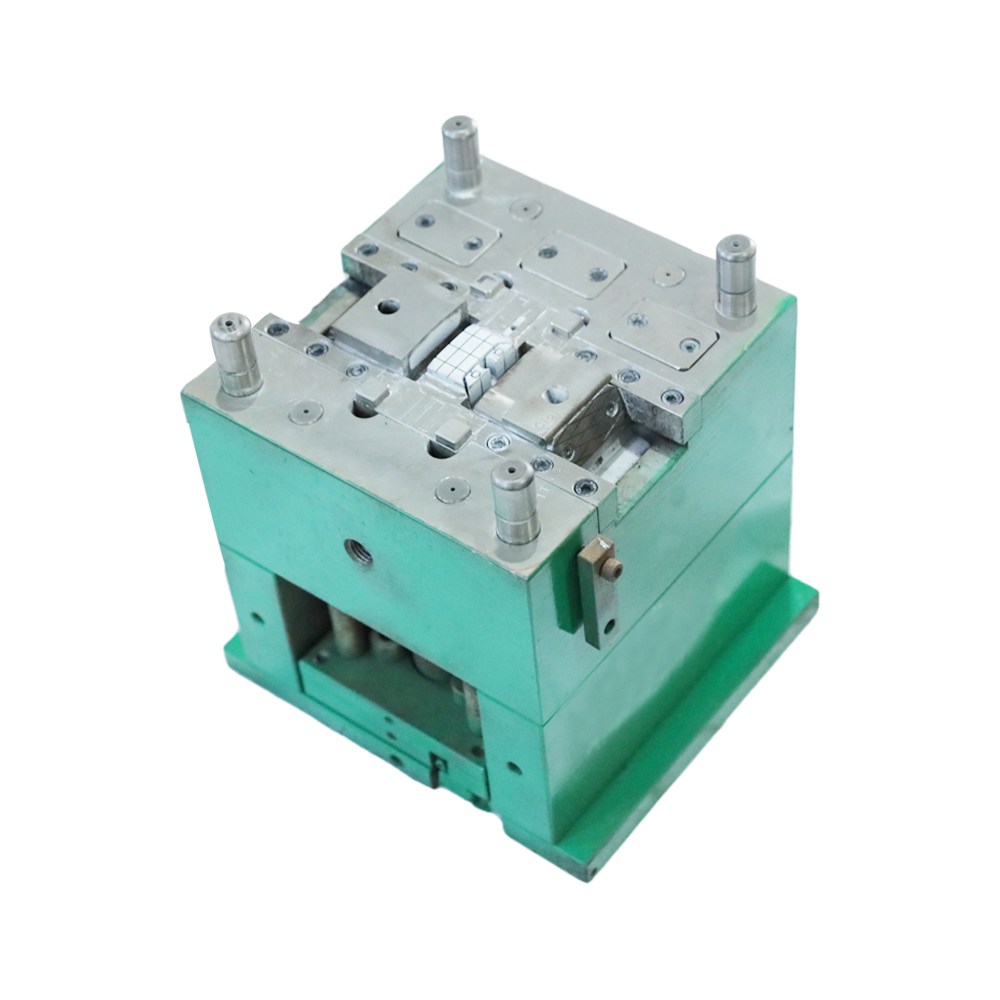

Suzhou Huihong Electric Co., Ltd. is a professional manufacturer of precision molds, injection molding, assembling and silk-printing. Socket top shell mold Suppliers. Some moulds are exported to Japan, Europe and the United States. We have the right to import and export the goods. As Custom Socket top shell mold Maker, We can develop and manufacture the moulds according to the needs of our customers. We pay attention to quality control, new project development, personnel training, team spirit. In recent years, we have established long-term business relationships with many well-known enterprises at home and abroad.

5 years of experience in bath bar moulding

20 years of experience in mold making for vacuum cleaner

15 years of experience in mold making for power tools

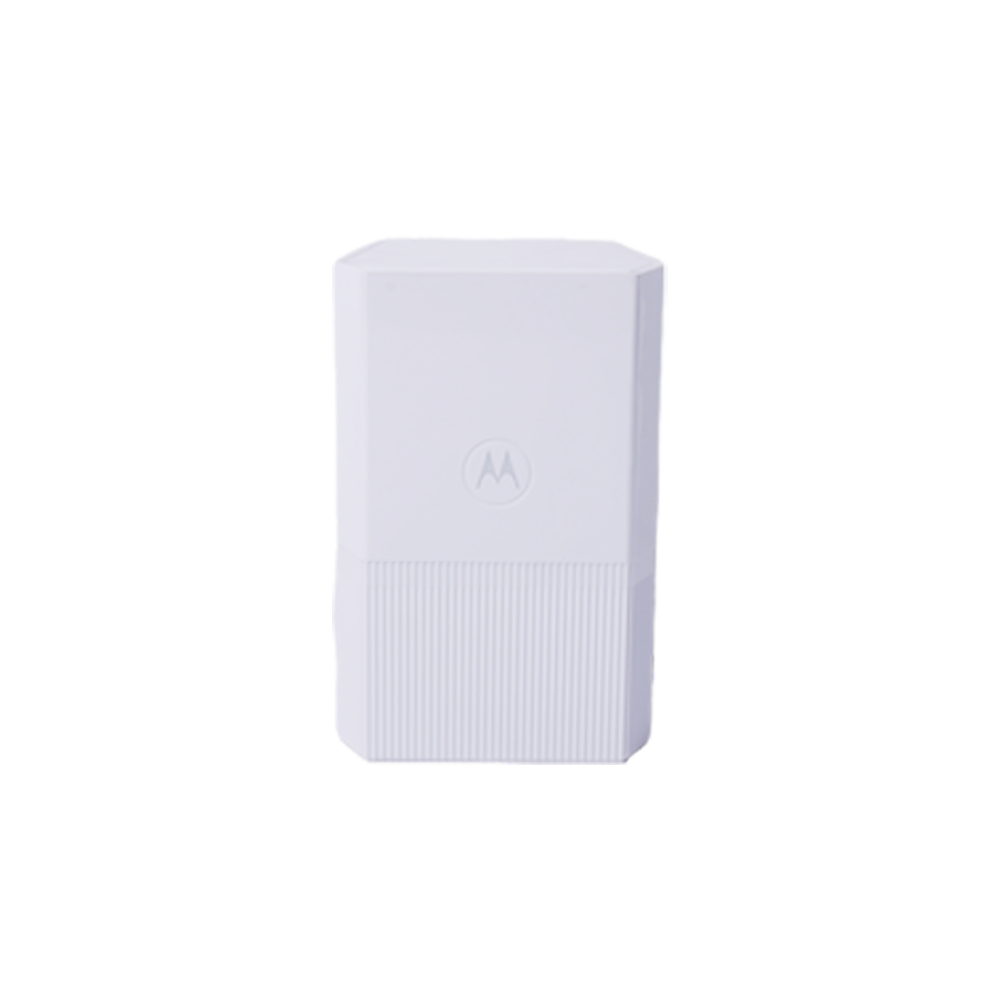

10 years of experience in router mold making

10 years of experience in mold making for coffee machine

Bathroom parts circuit board cover mold

Breath collector upper cover mold

Router front cover mold

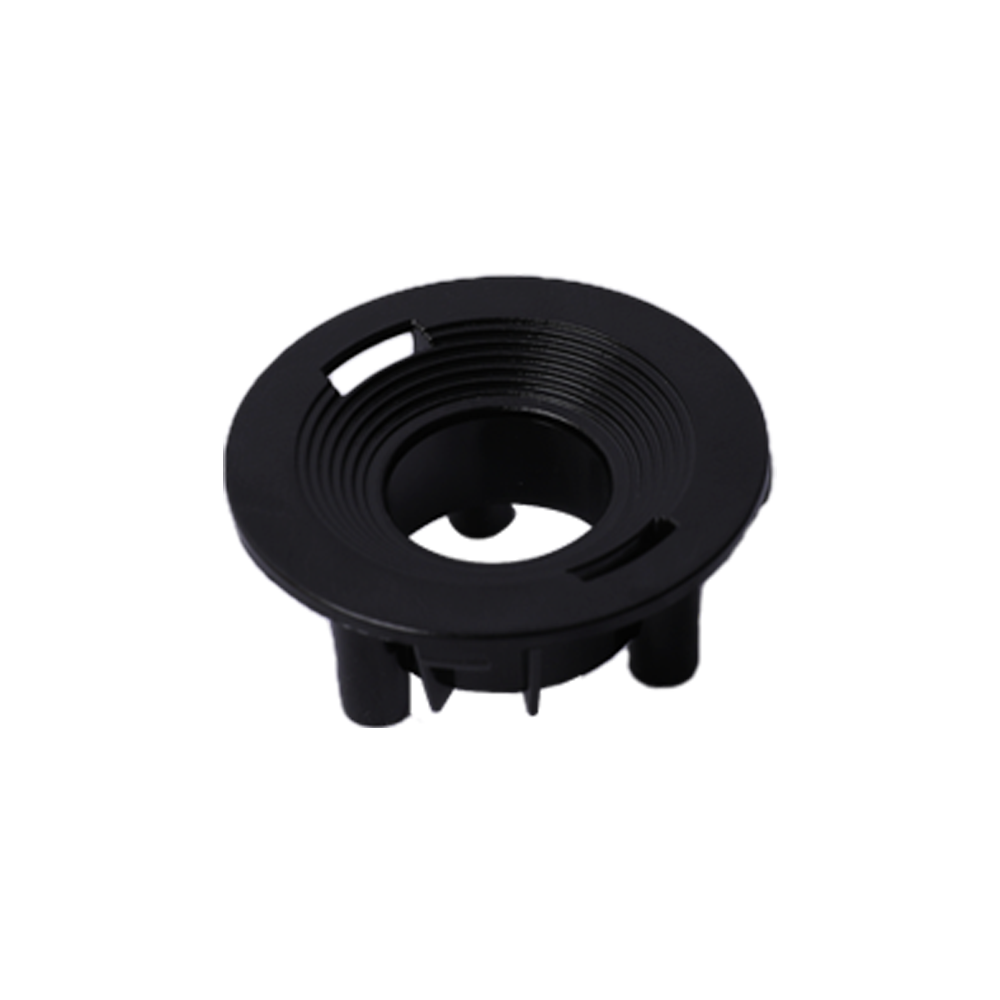

Color detector lens ring mold

Cell phone holder lower clamping mold

Socket top shell mold

Router back shell mold

Vacuum cleaner front cover mould

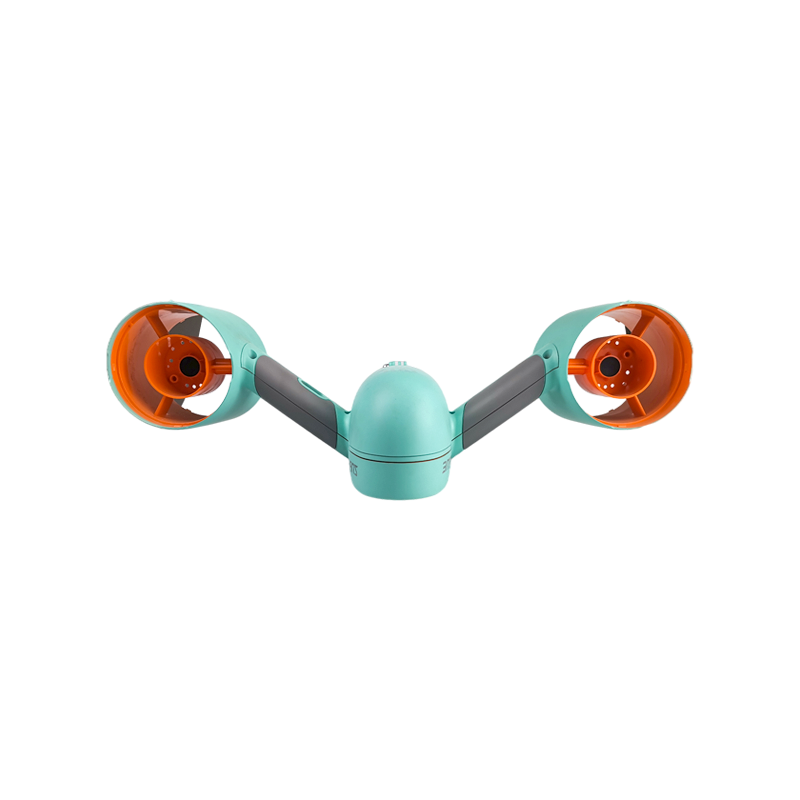

Underwater drone body mold

Nail gun shell mould

Auto Air Conditioner Bracket Mould

Vacuum cleaner interface mold