+86-15995701933

+86-15995701933 [email protected]

[email protected]- OEM Plastic Mould Manufacturers

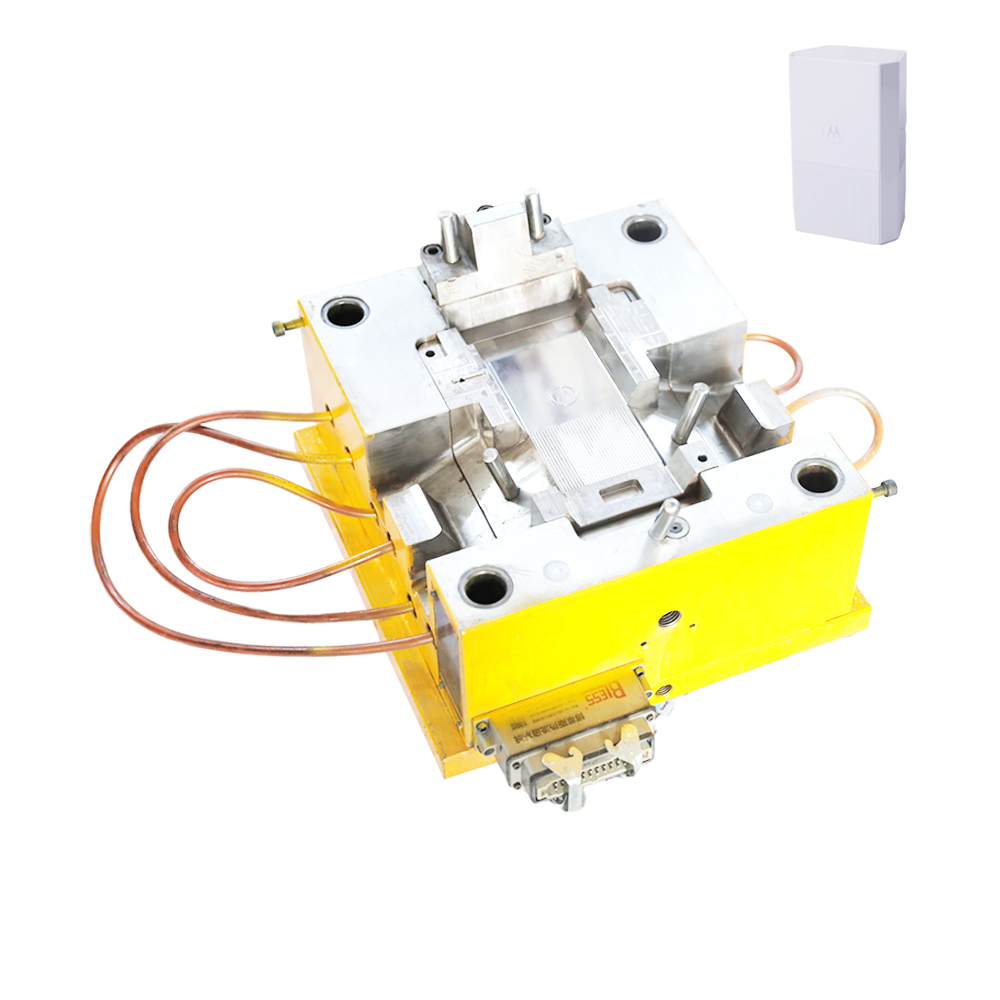

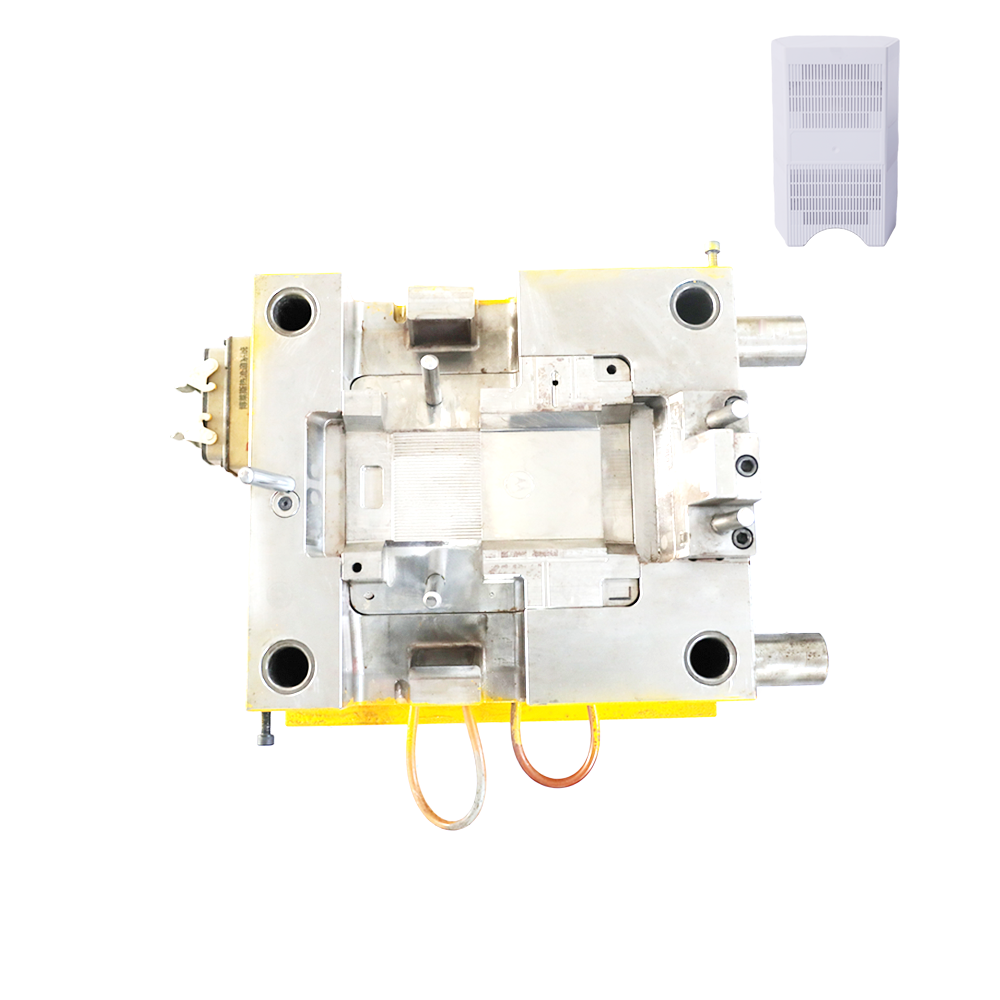

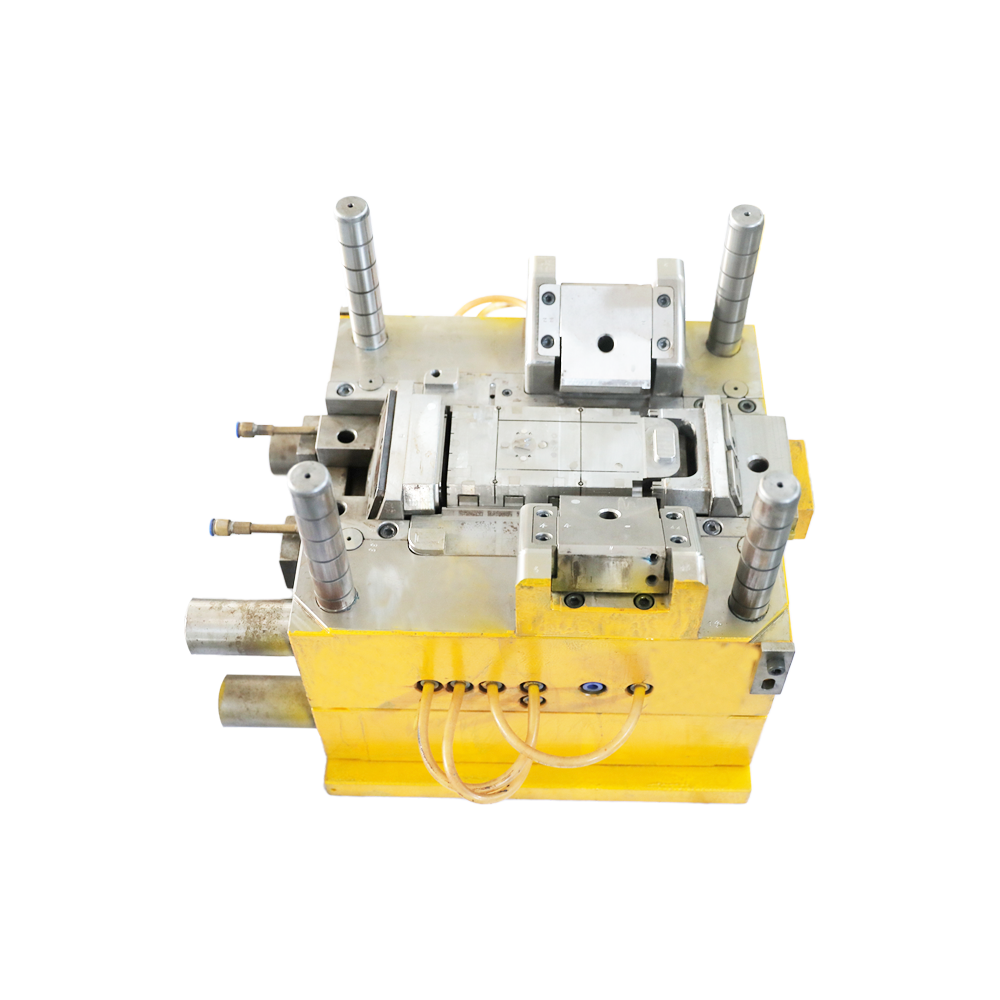

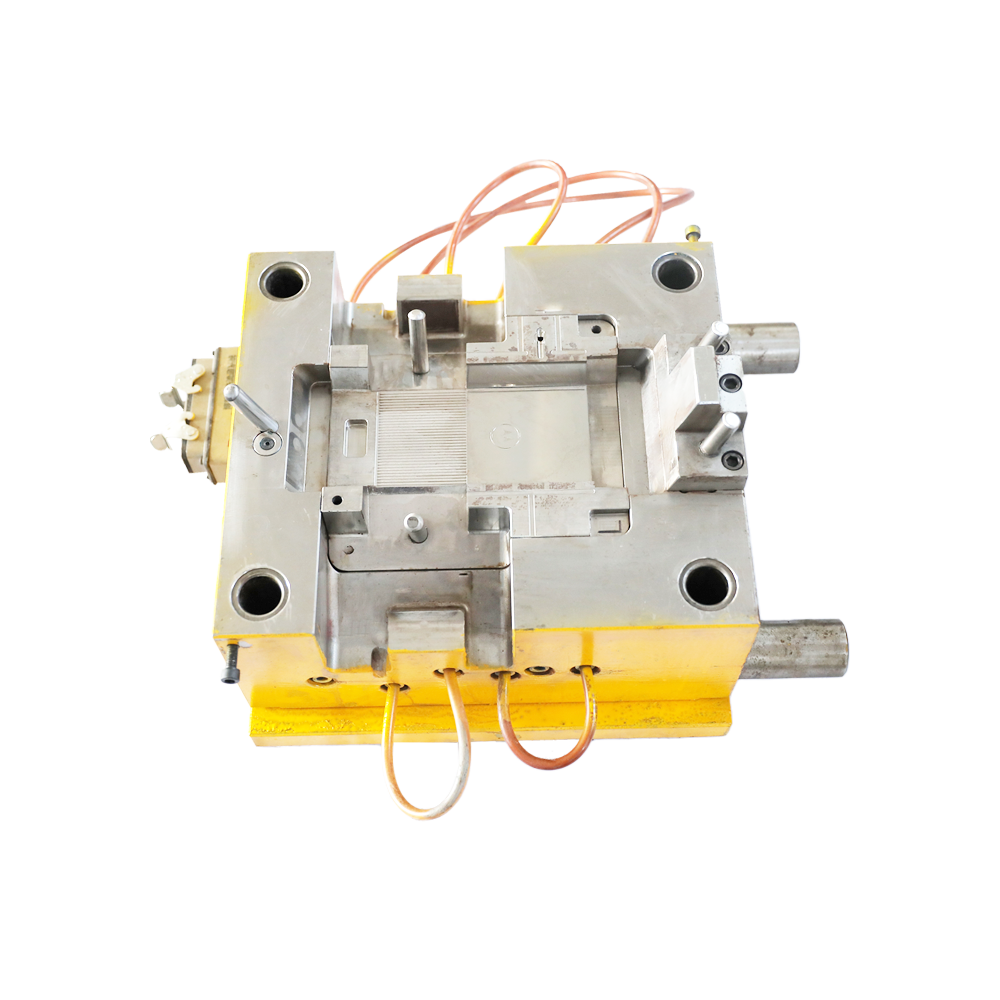

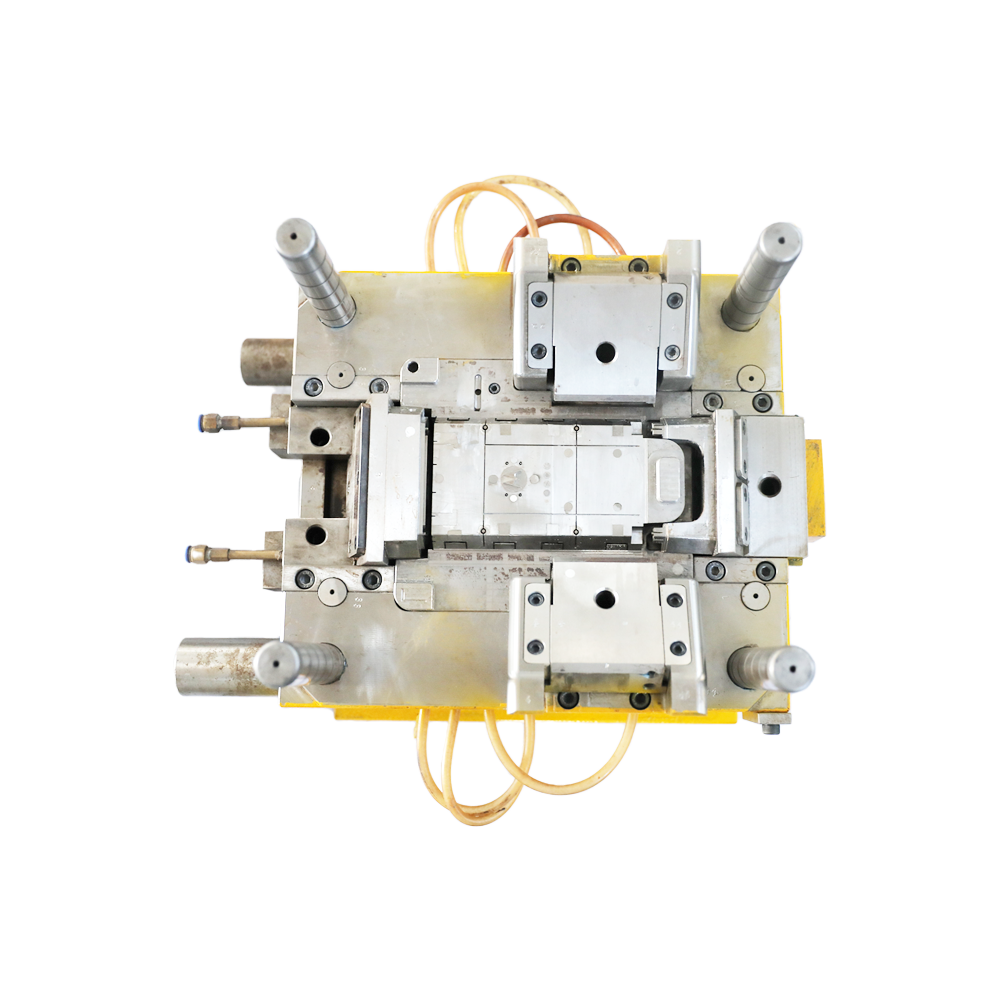

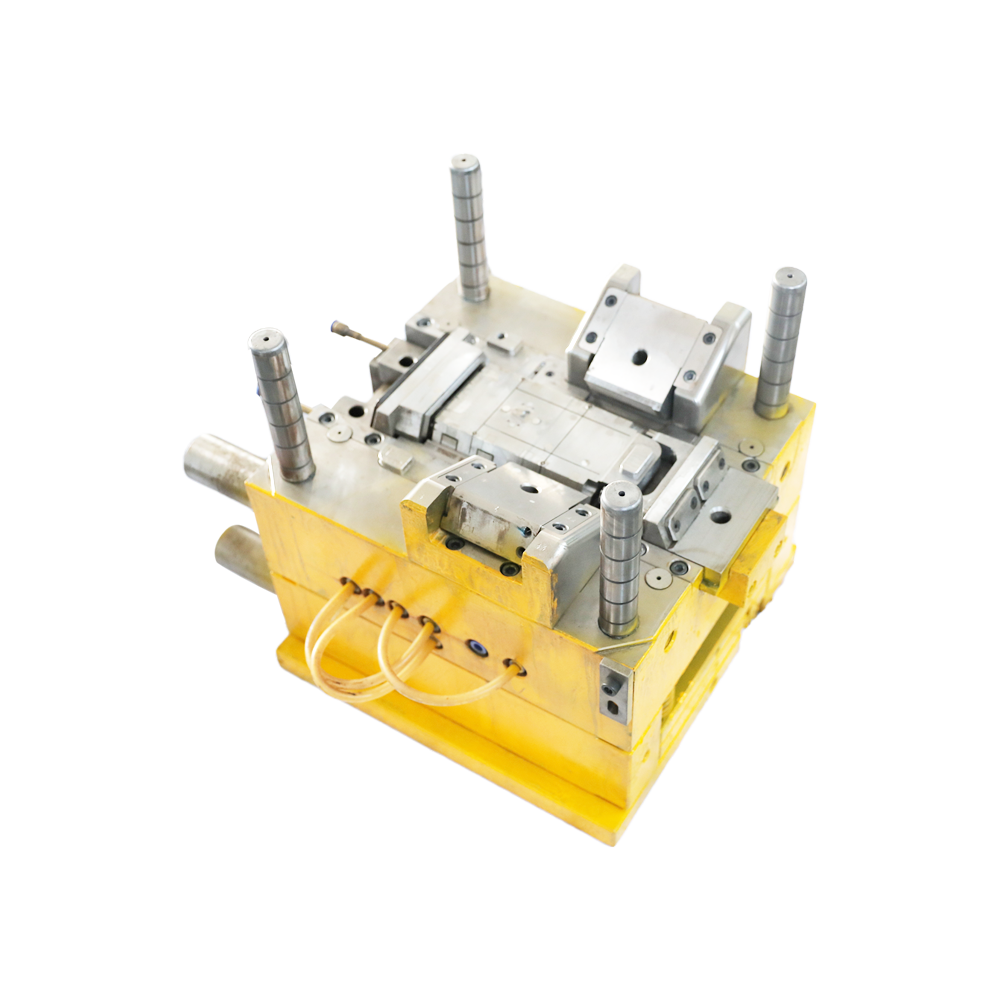

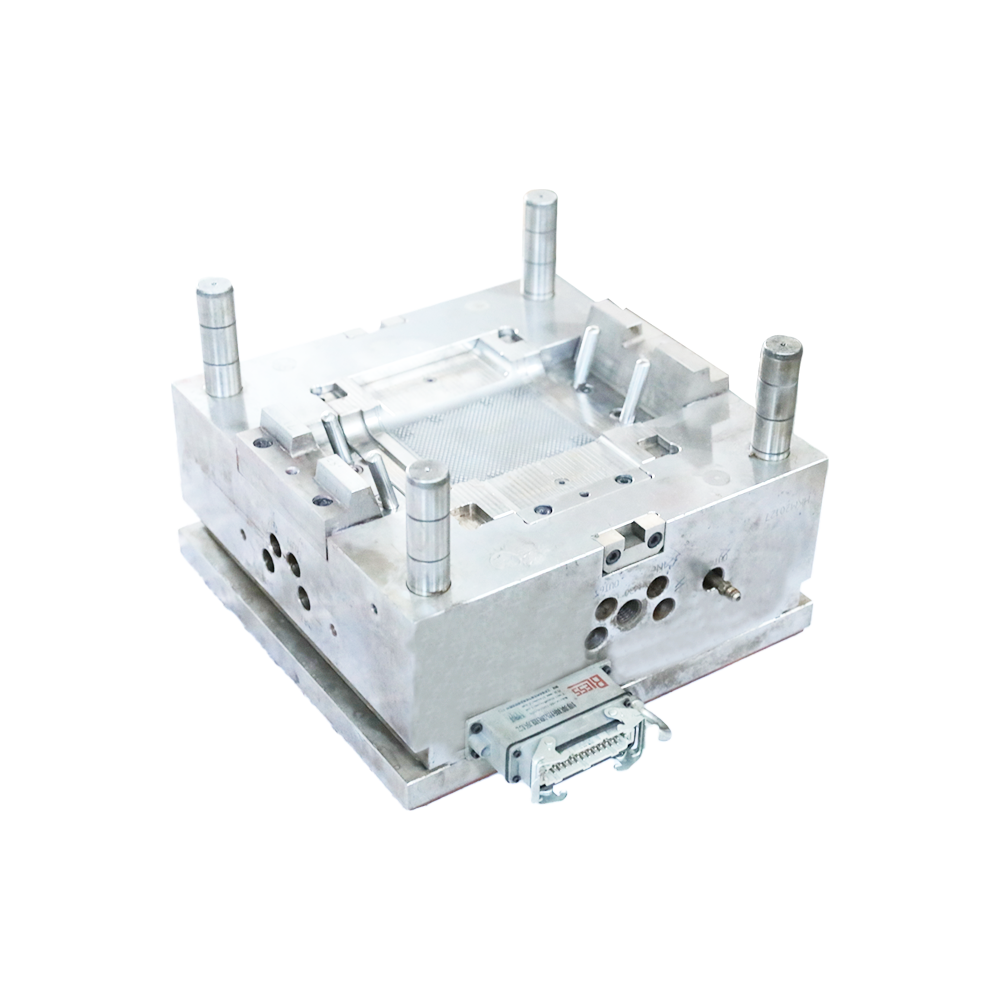

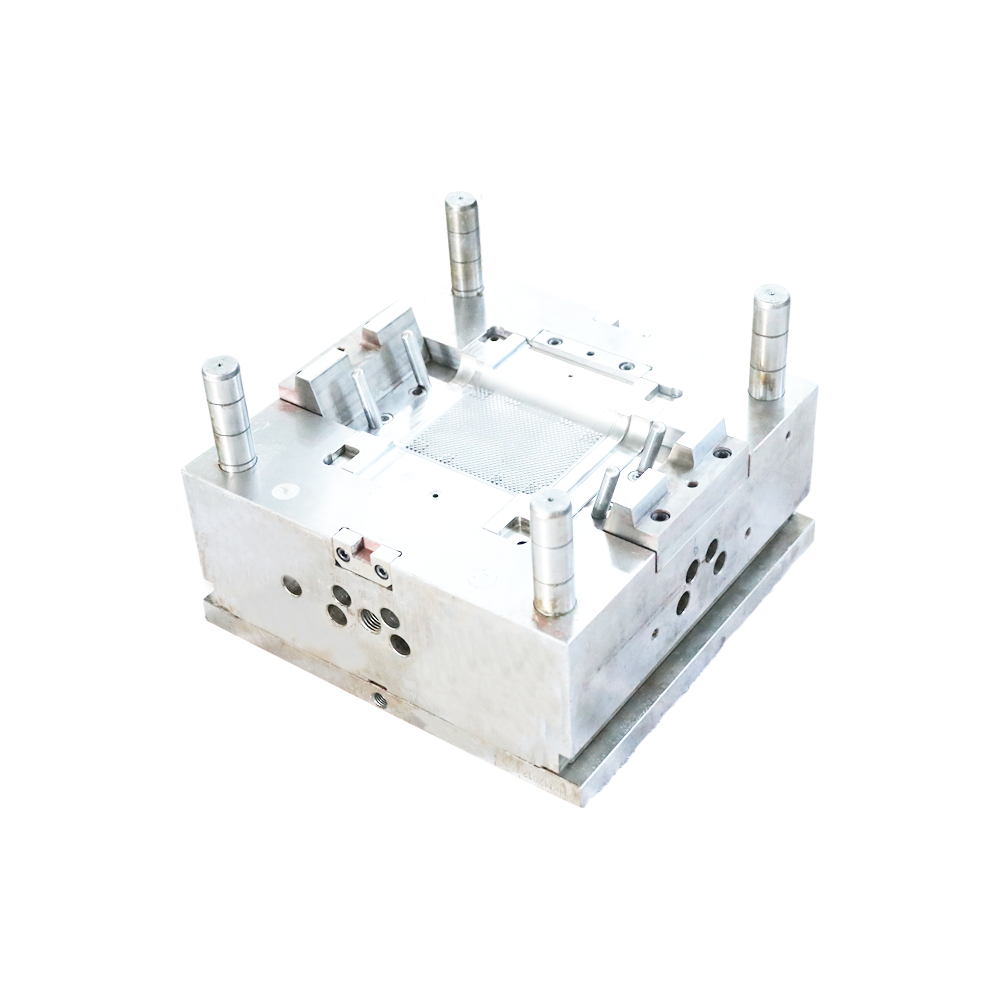

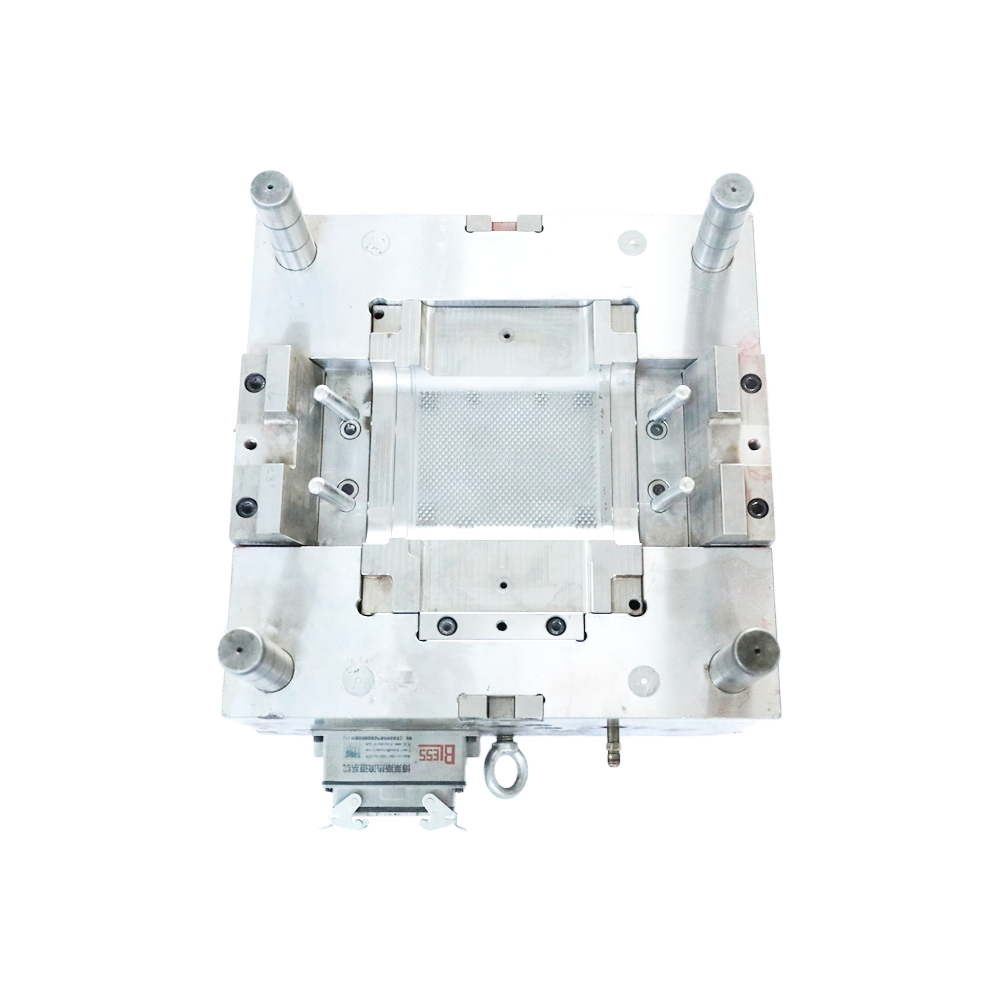

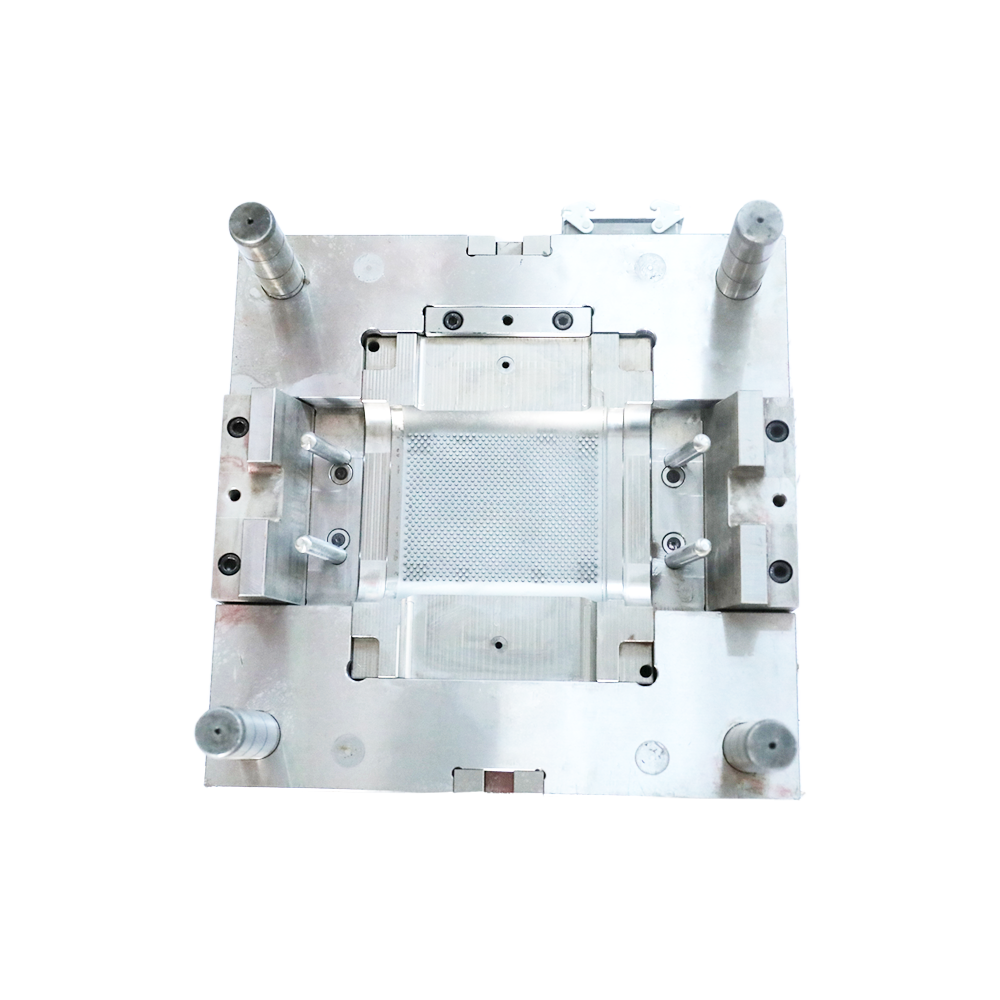

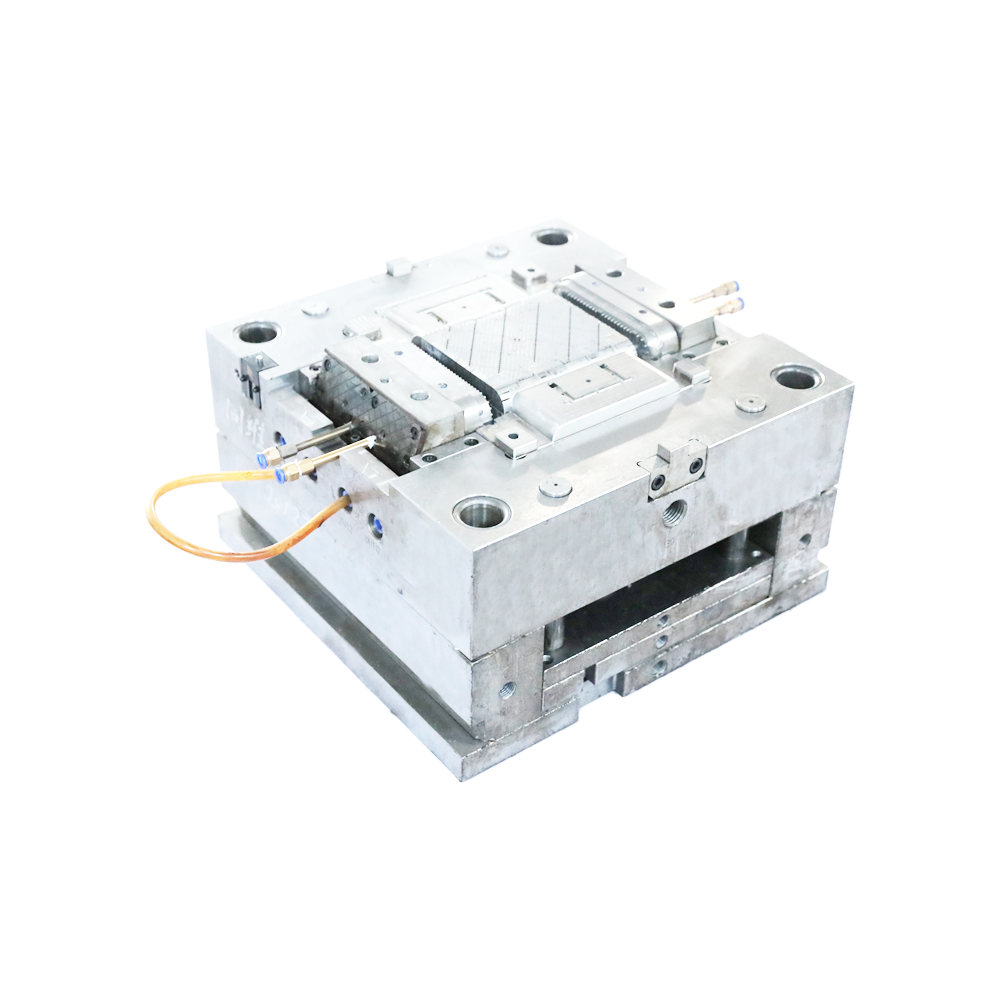

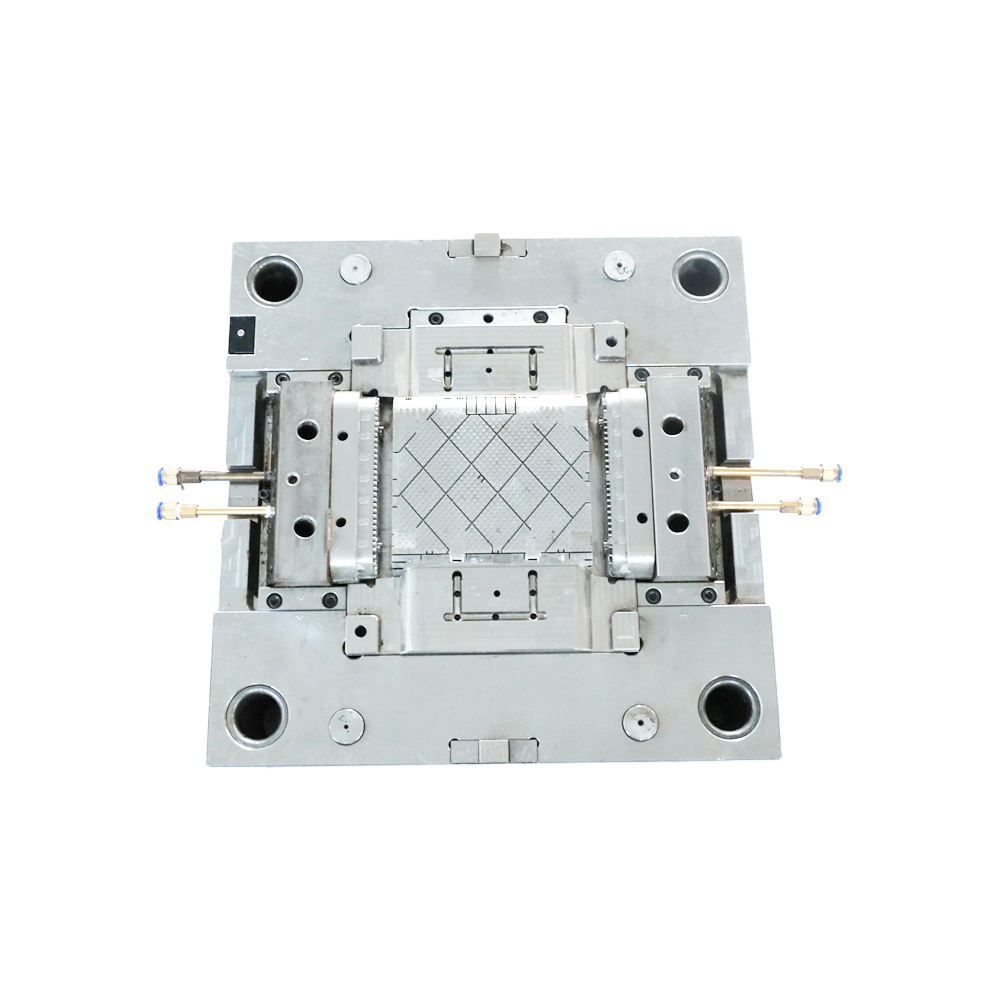

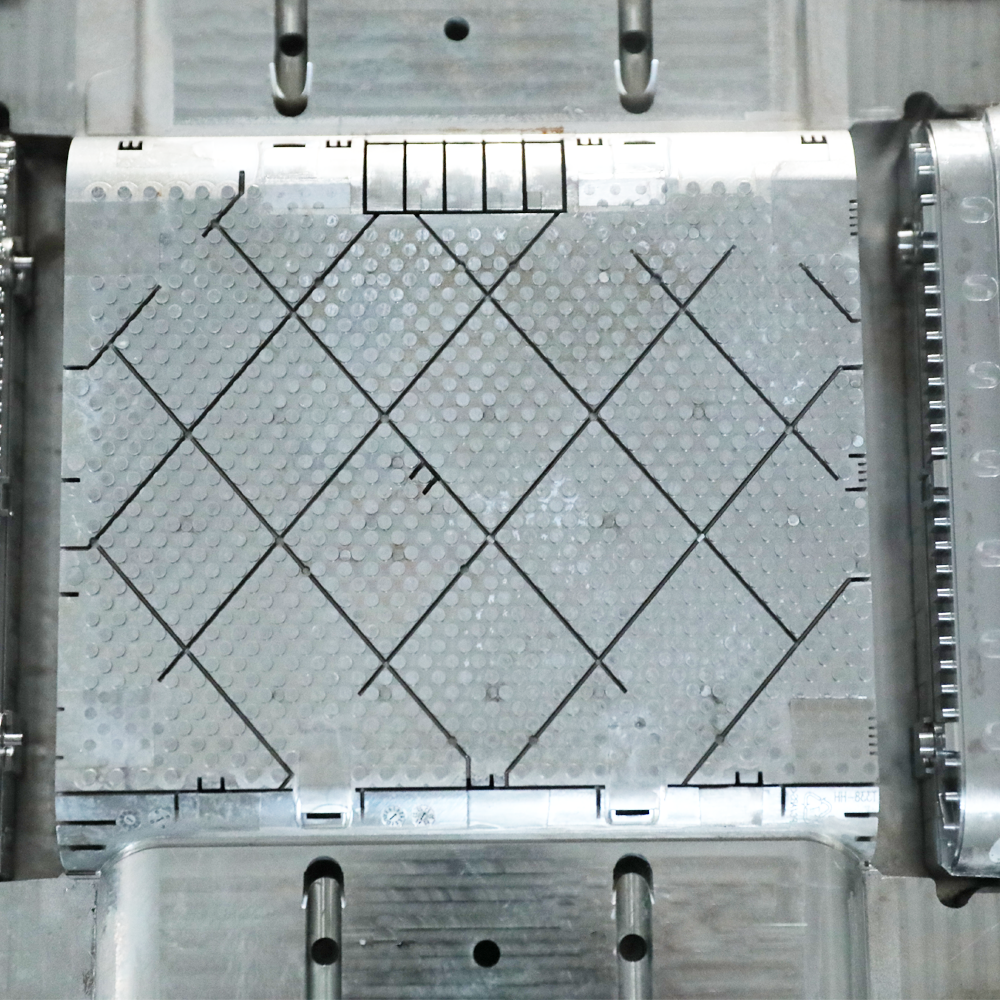

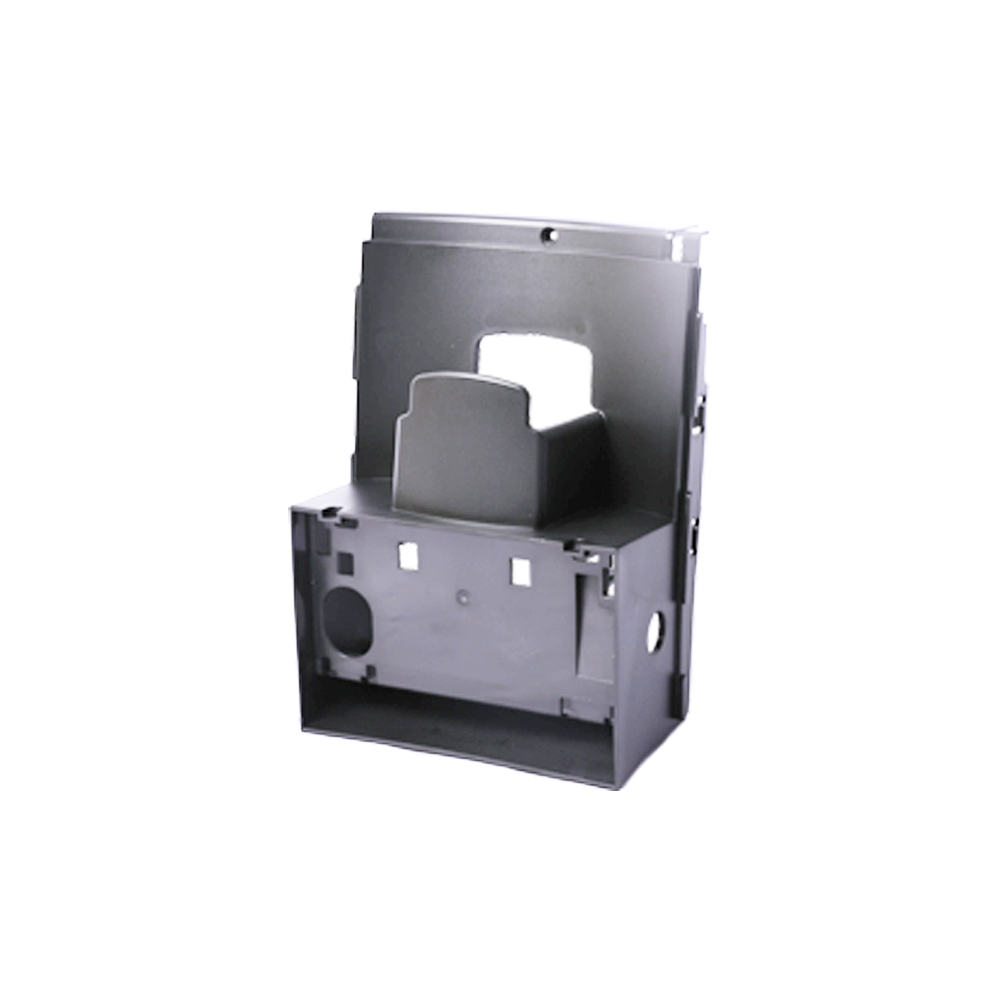

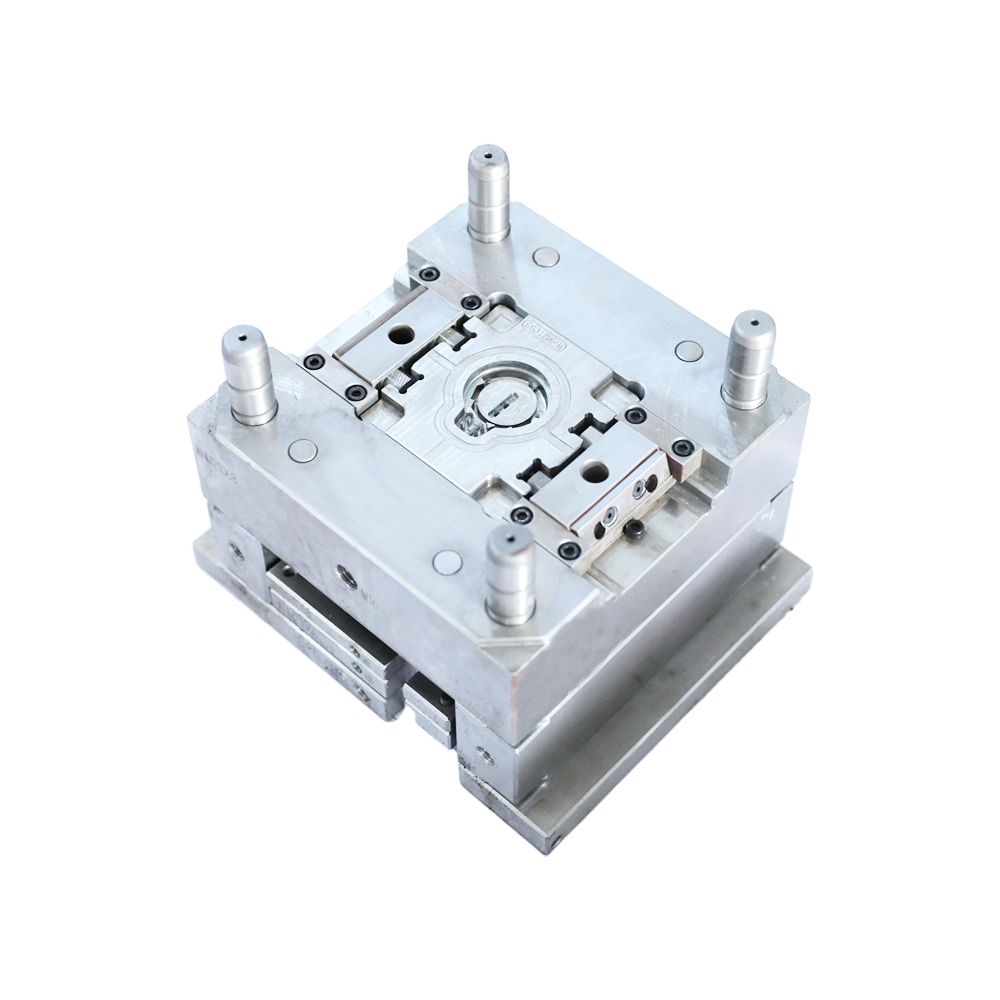

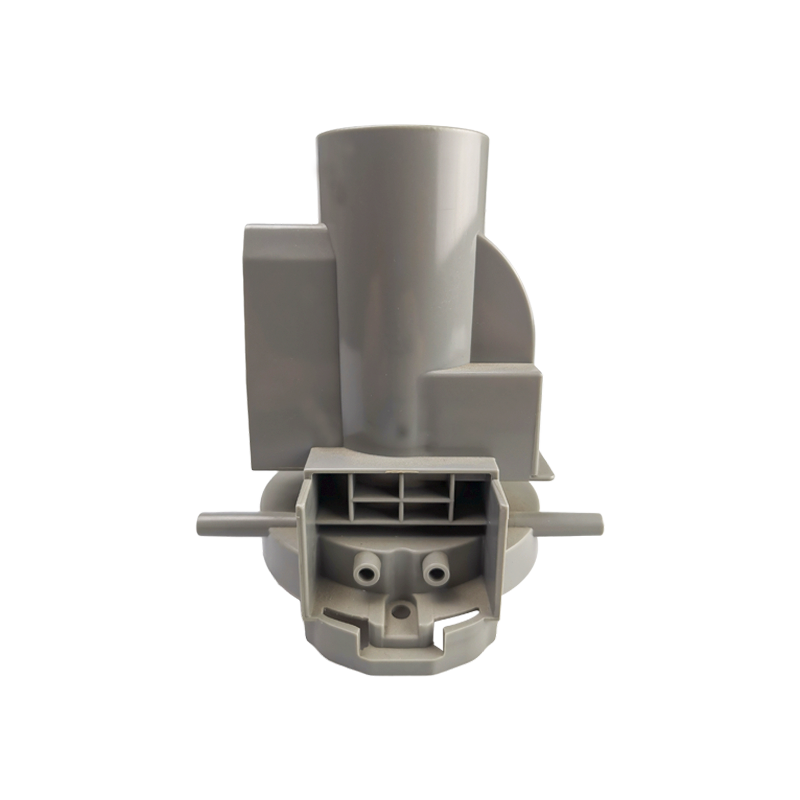

If you are looking for a way to mold the front cover of a Router, there are several options. One of the most common options is a two-cavity mold layout. The best gate location depends on several factors, including the size of the part, its parting location, and the appearance requirements of the product. This method simplifies the mold structure and improves the reliability. This type of mold also utilizes a single side gate located in the center of the part in the length direction. In addition, dual-gate runner systems are proposed when the part is larger in length.Another option is a two-cavity injection mould. The two-gate plan reduces wall shear stress and clamping force. The advantages of dual-gate molds over single-gate plans are smaller clamping force, less air trapped inside, and fewer defects in the finished part. This mold allows for easier removal of the top cover mold without affecting quality.

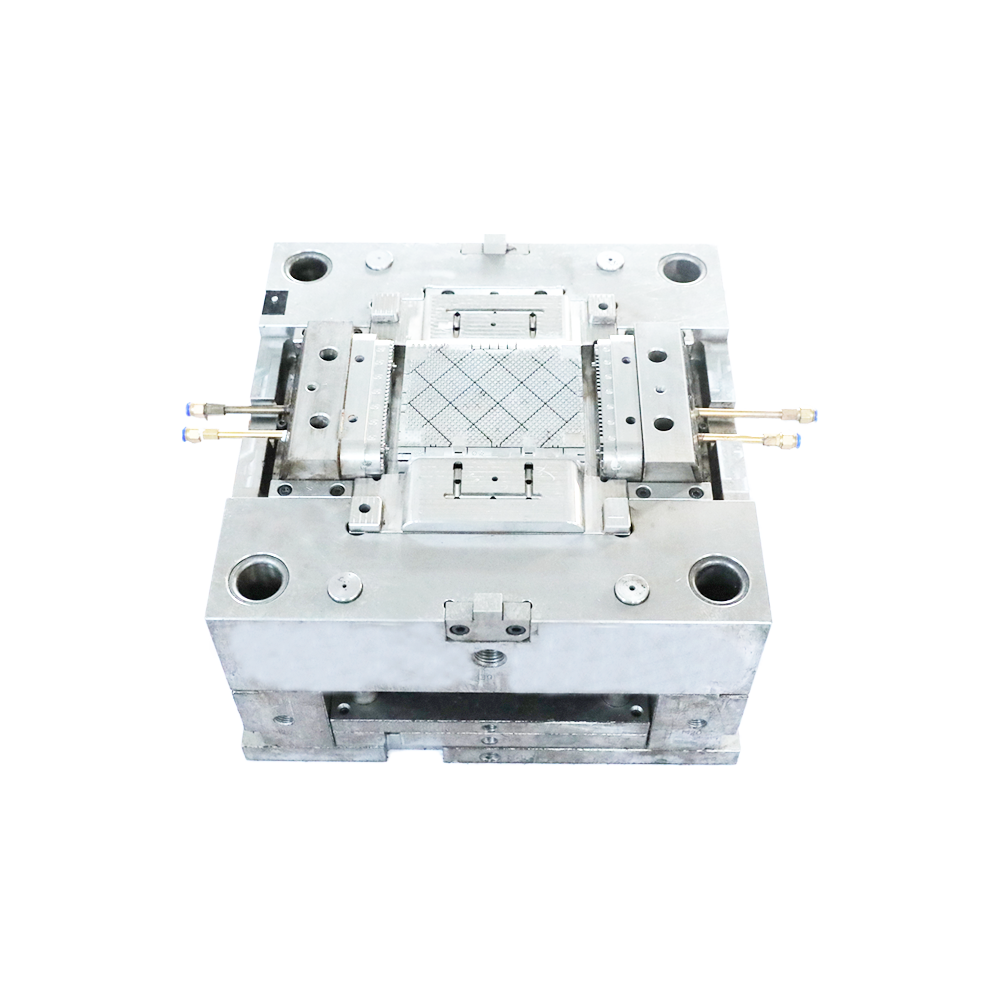

| Mold Name | Router front cover mould |

| Product Material | ABS |

| Mold Steel for cavity | NAK80 |

| Mold Steel For Core | NAK80 |

| Steel For Base | S50C |

| Mold Estimated Size | 450*450*524mm |

| Mold Weight | 650kg |

| Press Machine Size | 250T |

| MOQ | 1 Set |

| Trade Terms | FOB |

| Payment Terms | 50% prepayment before design making, 50% payment after final sample is confirmed. |

Suzhou Huihong Electric Co., Ltd. is a professional manufacturer of precision molds, injection molding, assembling and silk-printing. Router front cover mold Suppliers. Some moulds are exported to Japan, Europe and the United States. We have the right to import and export the goods. As Custom Router front cover mold Maker, We can develop and manufacture the moulds according to the needs of our customers. We pay attention to quality control, new project development, personnel training, team spirit. In recent years, we have established long-term business relationships with many well-known enterprises at home and abroad.

5 years of experience in bath bar moulding

20 years of experience in mold making for vacuum cleaner

15 years of experience in mold making for power tools

10 years of experience in router mold making

10 years of experience in mold making for coffee machine

Coffee machine parts mold

Breath collector upper cover mold

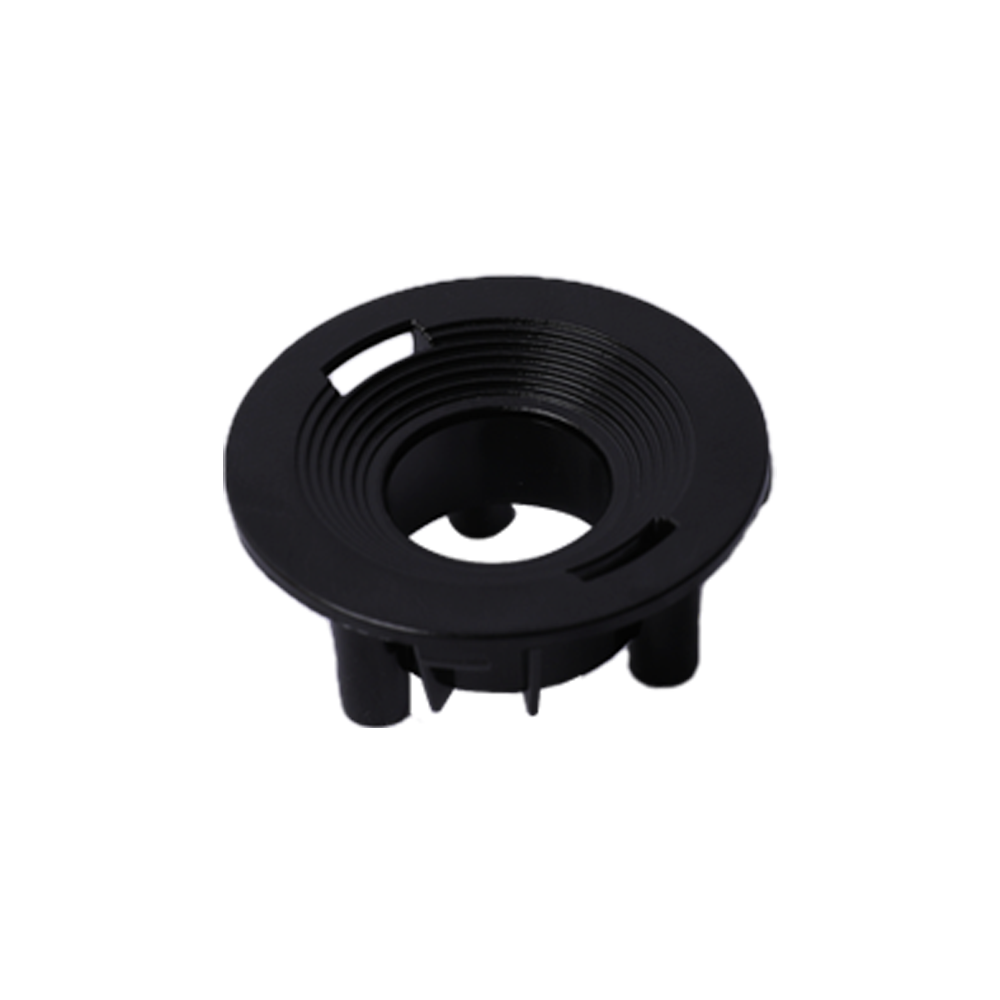

Color detector lens ring mold

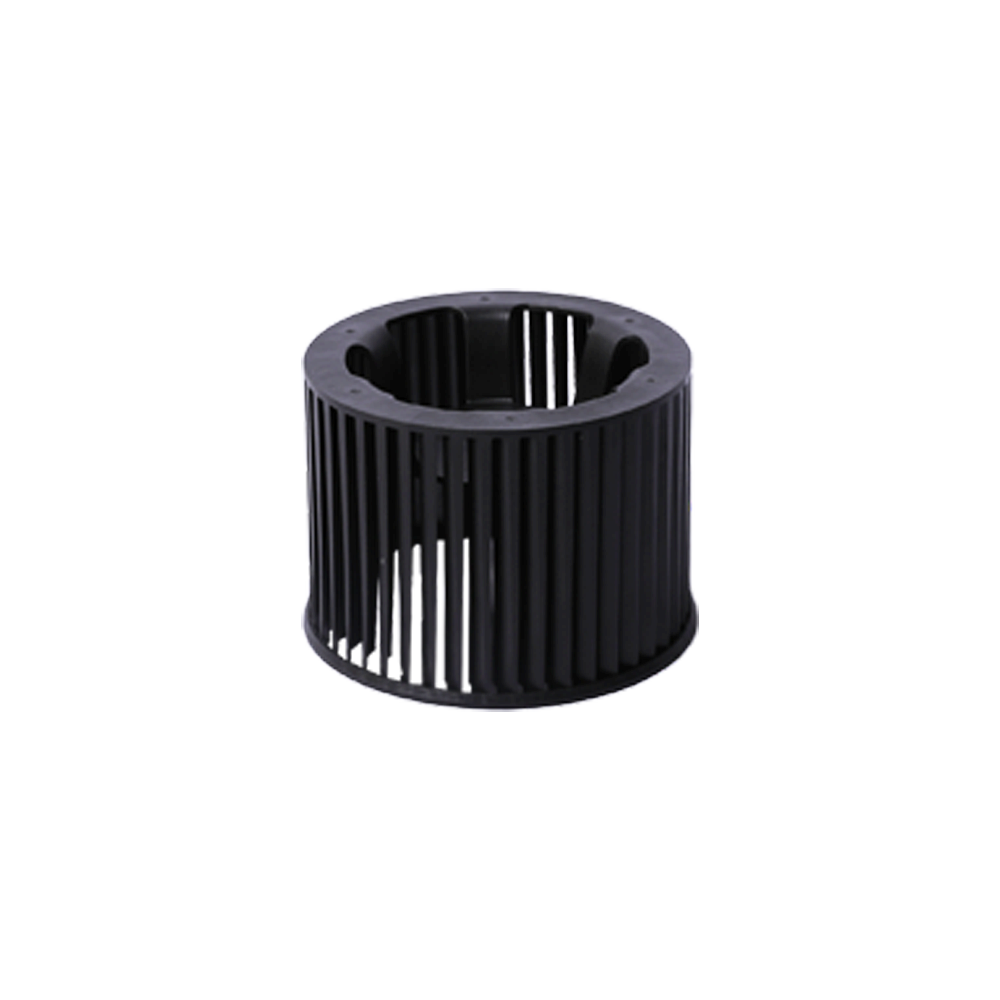

Bath exhaust fan blade mold

Nespresso coffee chiller back cover mold

Infrared transceiver cover shell mold

Vacuum cleaner front cover mould

Colorimeter

Auto air conditioning body mold

Auto control panel mould

Automotive operation screen mold

Vacuum cleaner interface mold