+86-15995701933

+86-15995701933 [email protected]

[email protected]- OEM Plastic Mould Manufacturers

The process of designing an automotive operation screen mold is a complex one, with many different variables. This process is made possible by liquid crystal display technology. Liquid crystal displays have many different layers, and each layer must be cut to create a freeform pattern.The mold has side cores, which are projections that core the holes in the product. The part is then ejected from the mold.

Two-shot molding is another process used in manufacturing automotive operation screens. The process can be used on parts such as instrument panels, dashboards, and center consoles.These molds are easy to install and maintain, and the entire process is highly automated.

| Mold Name | Car operating screen mold |

| Product Material | PC+ABS (V0) |

| Mold Steel for cavity | NAK80 |

| Mold Steel For Core | NAK80 |

| Steel For Base | S50C |

| Mold Estimated Size | 600*450*470mm |

| Mold Weight | 900kg |

| Press Machine Size | 368T |

| MOQ | 1 Set |

| Trade Terms | FOB |

| Payment Terms | 50% prepayment before design making, 50% payment after final sample is confirmed. |

Suzhou Huihong Electric Co., Ltd. is a professional manufacturer of precision molds, injection molding, assembling and silk-printing. Automotive operation screen mold Suppliers. Some moulds are exported to Japan, Europe and the United States. We have the right to import and export the goods. As Custom Automotive operation screen mold Maker, We can develop and manufacture the moulds according to the needs of our customers. We pay attention to quality control, new project development, personnel training, team spirit. In recent years, we have established long-term business relationships with many well-known enterprises at home and abroad.

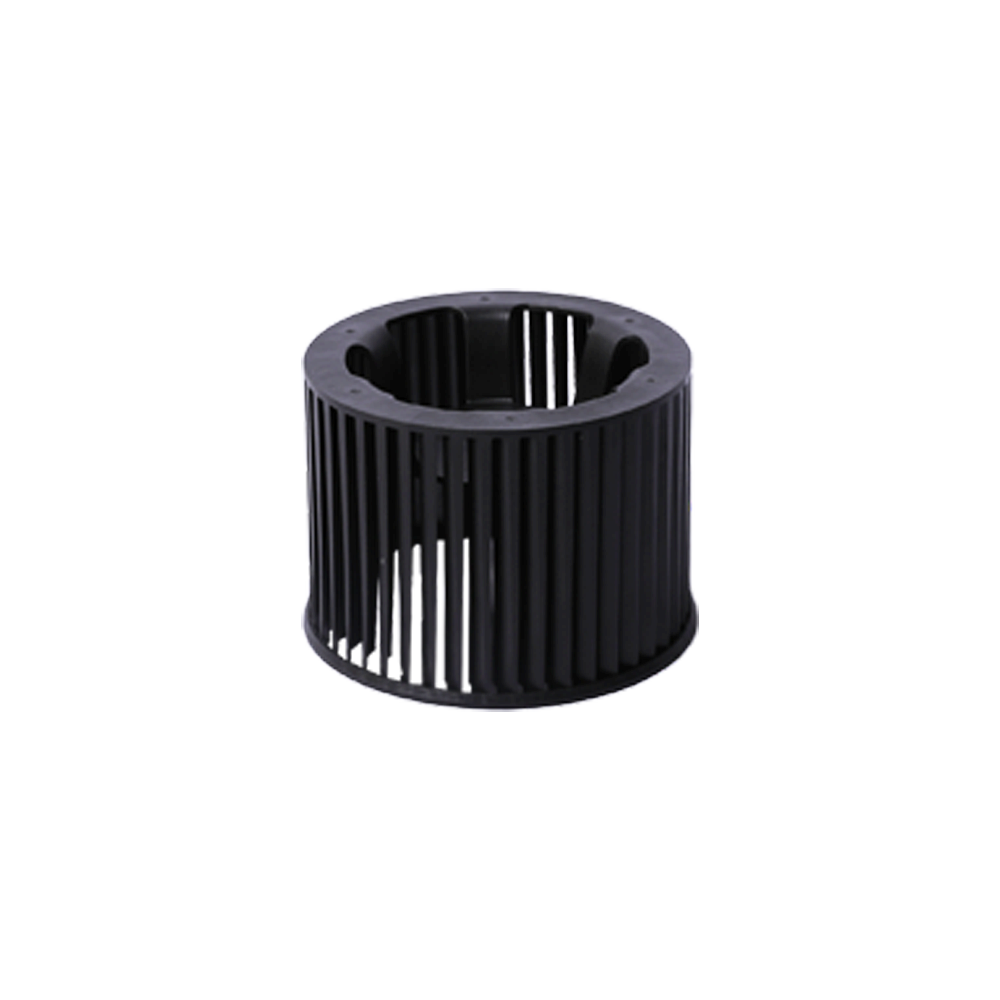

5 years of experience in bath bar moulding

20 years of experience in mold making for vacuum cleaner

15 years of experience in mold making for power tools

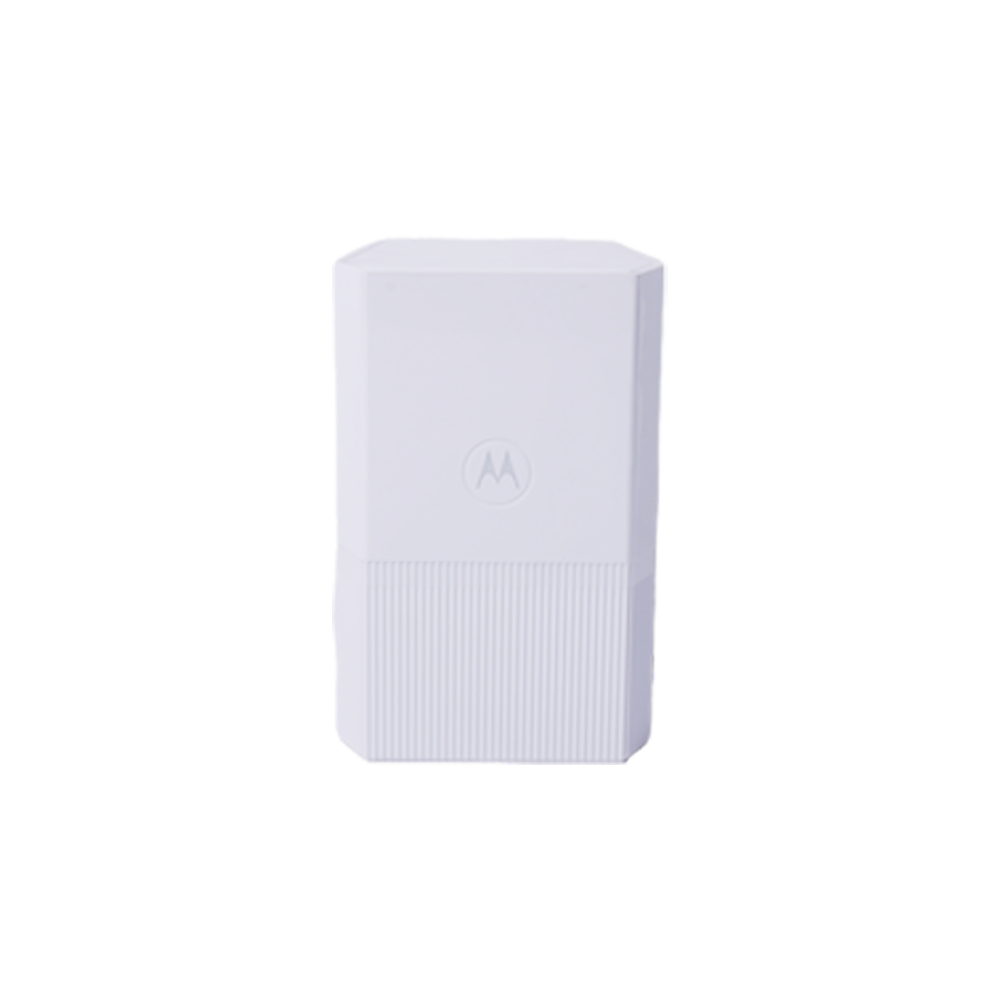

10 years of experience in router mold making

10 years of experience in mold making for coffee machine

Coffee machine parts mold

Router front cover mold

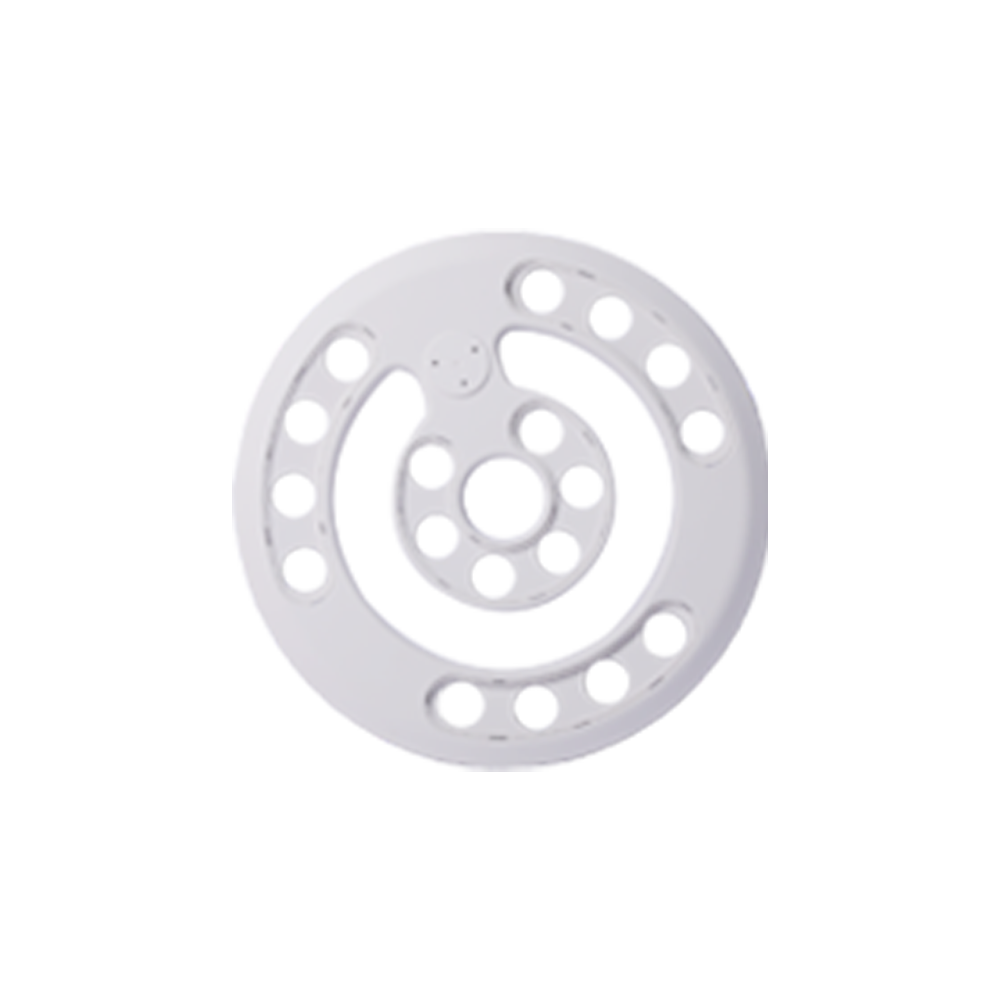

Surgical lamp front cover mould

Bath exhaust fan blade mold

Inverter housing mould

Socket top shell mold

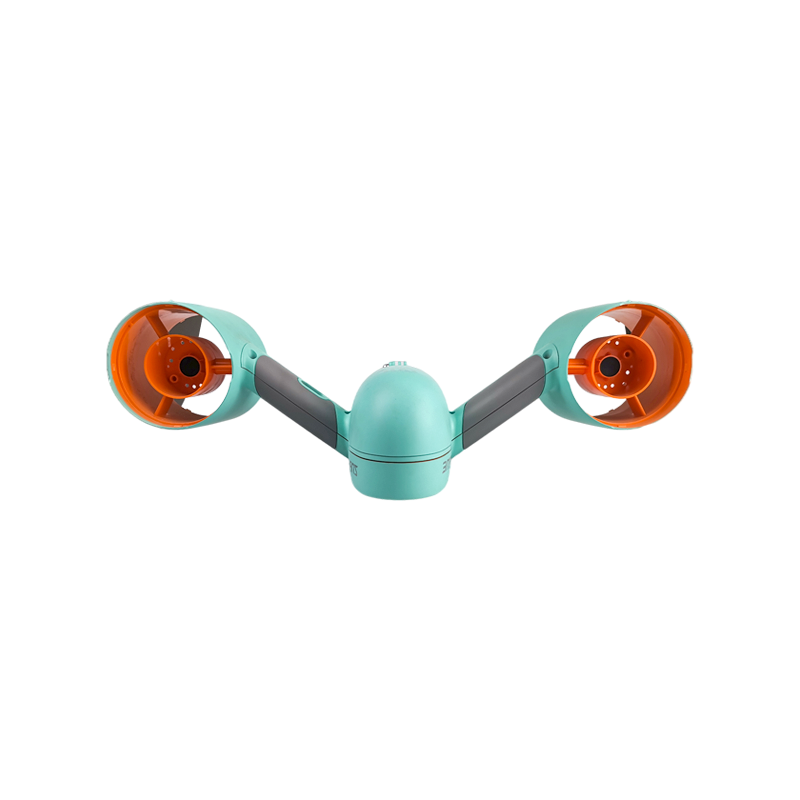

Underwater drone body mold

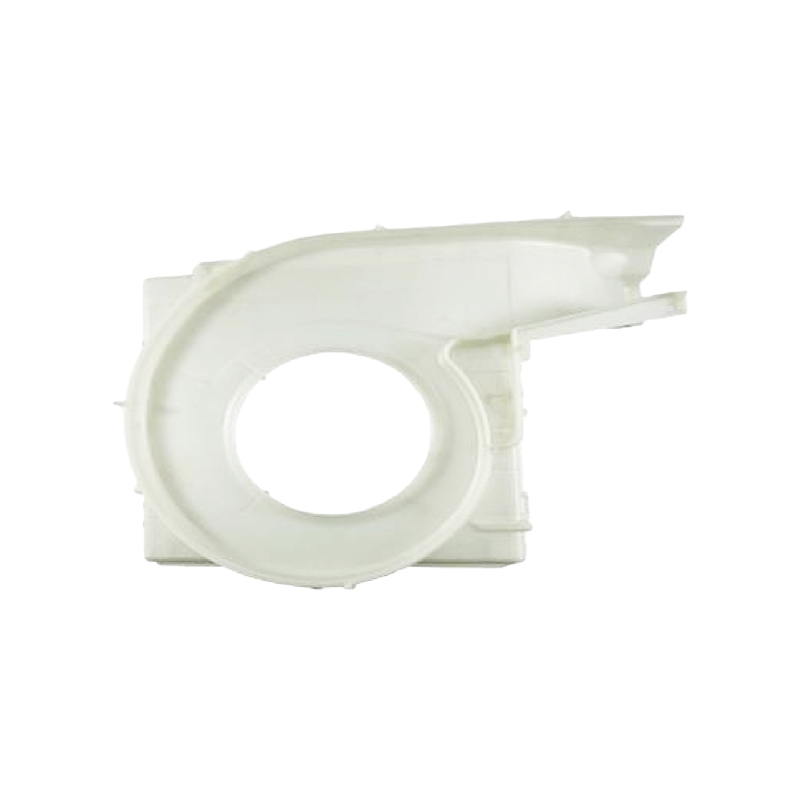

Auto air conditioner snail shell mold

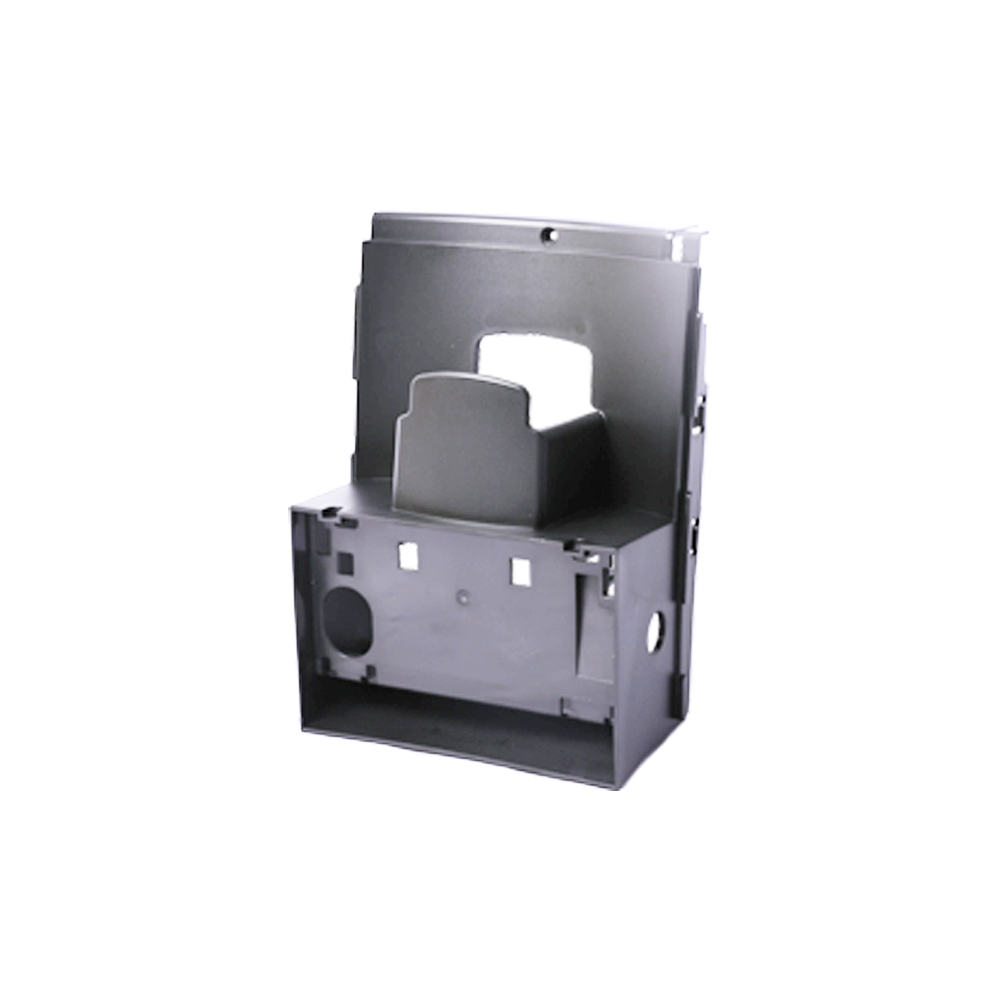

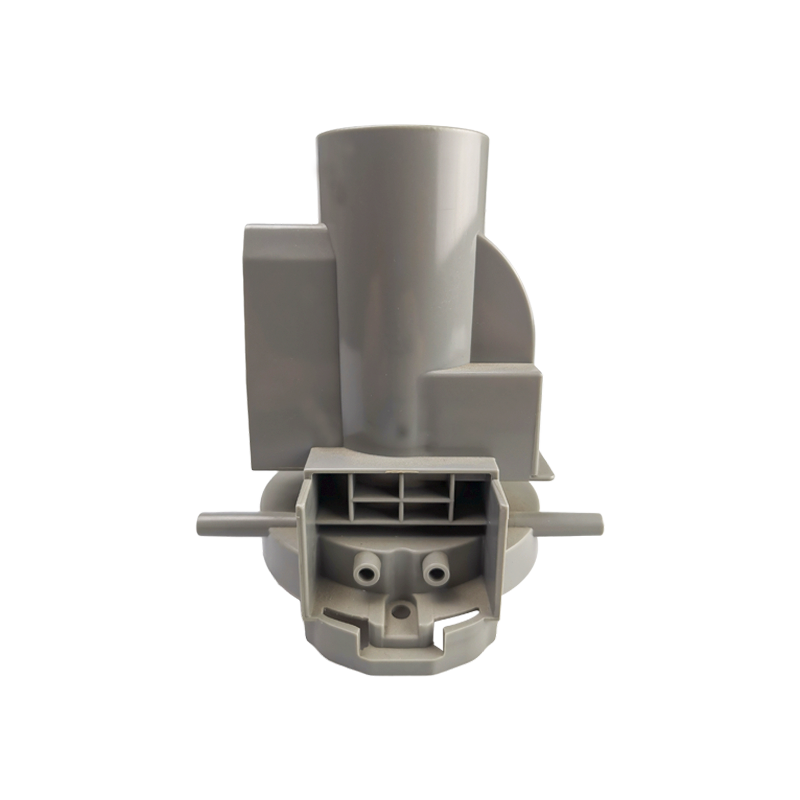

Auto control panel mould

Auto control panel mould

Injection parts automotive

Vacuum cleaner interface mold