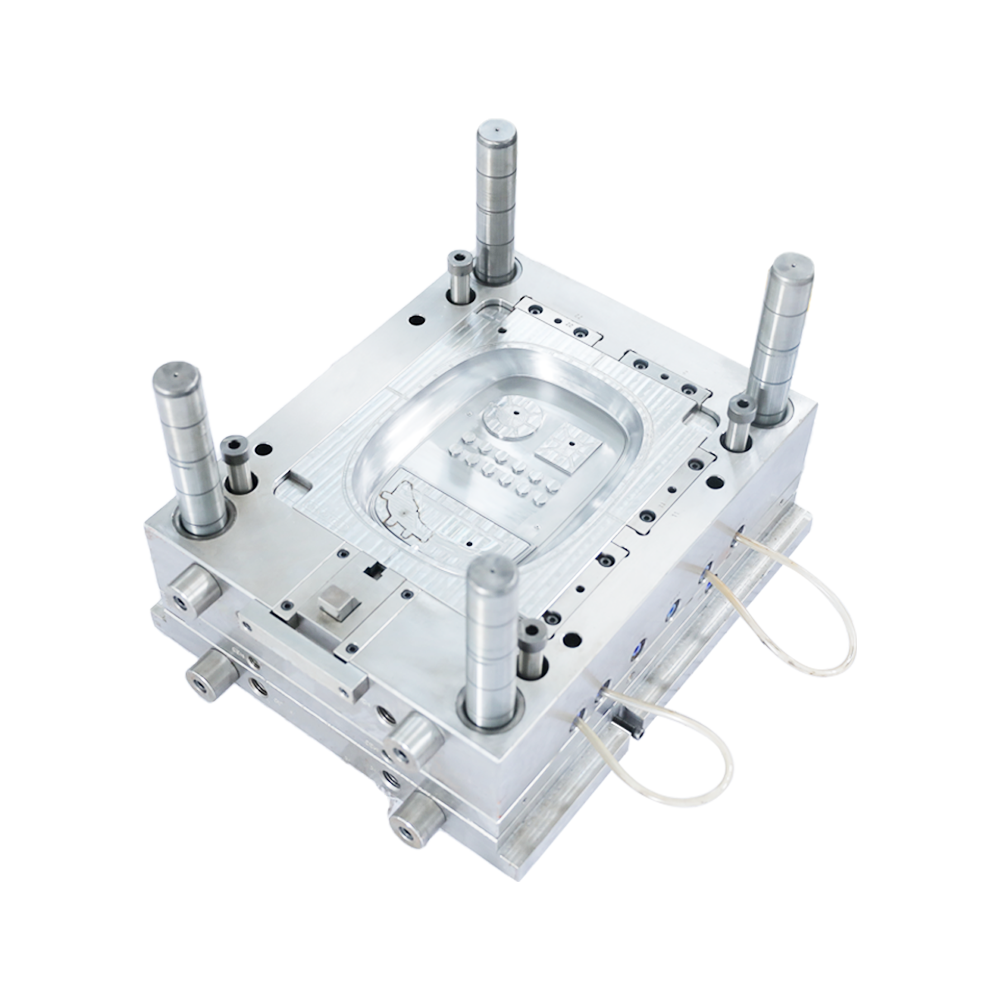

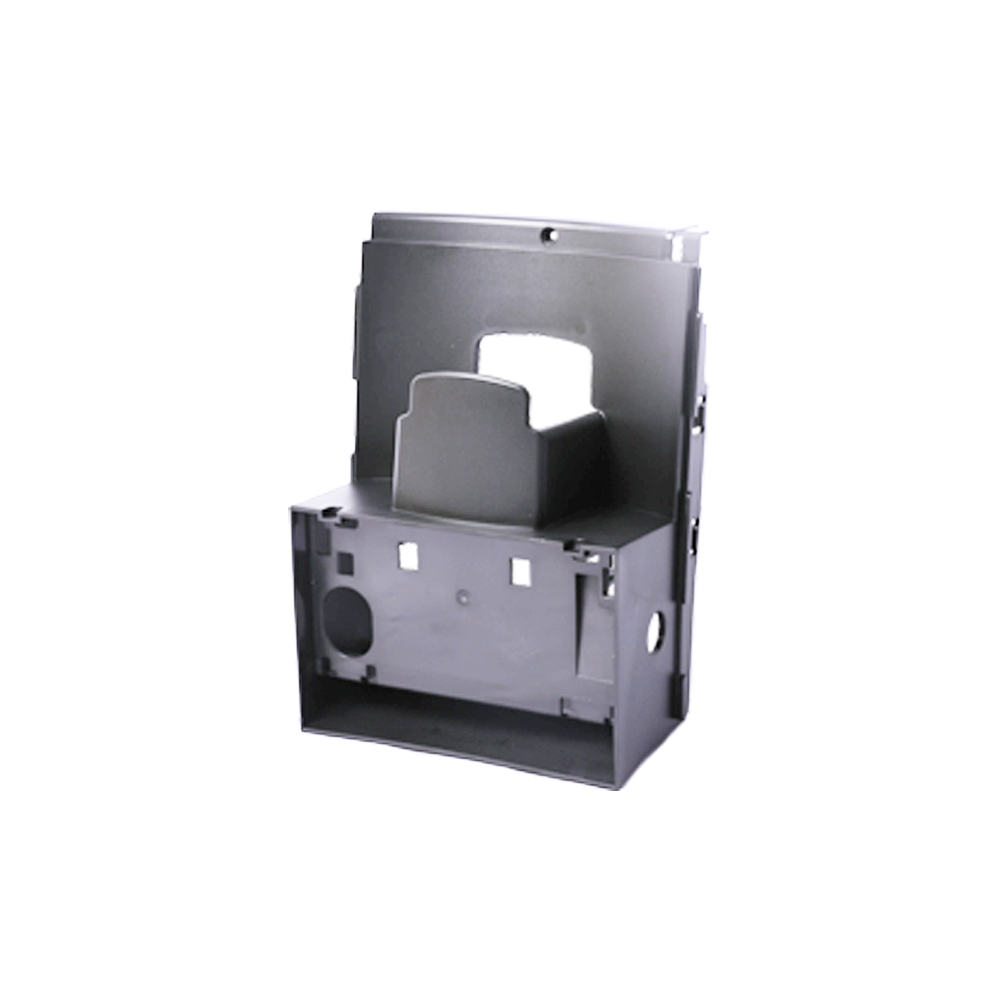

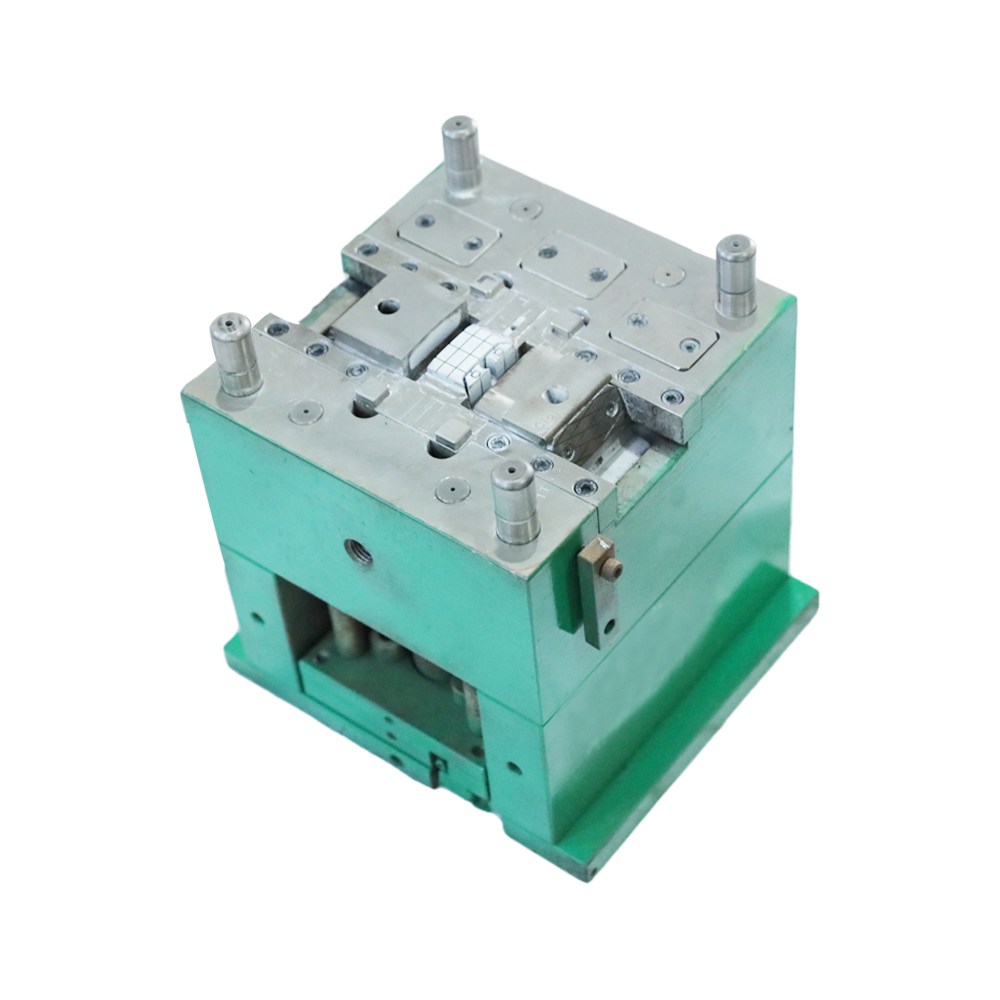

In a narrow sense, the automobile die is the general name of the die for punching all the stamping parts on the automobile body, that is, the "automobile body stamping die", for example, the flanging die for the top cover, the pressing die for the beam reinforcement plate, etc.

Now let's listen to the analysis of automobile mold processing factory. What are the requirements for automobile mold processing accuracy?

The manufacturing accuracy of die size shall be within 0.005~0.02mm; The perpendicularity shall be within the range of 0.01~0.02mm; Coaxiality shall be within 0.01~0.03mm; The parallelism of the upper and lower planes of the movable and fixed mold parting surfaces shall be within the range of 0.01~0.03mm.

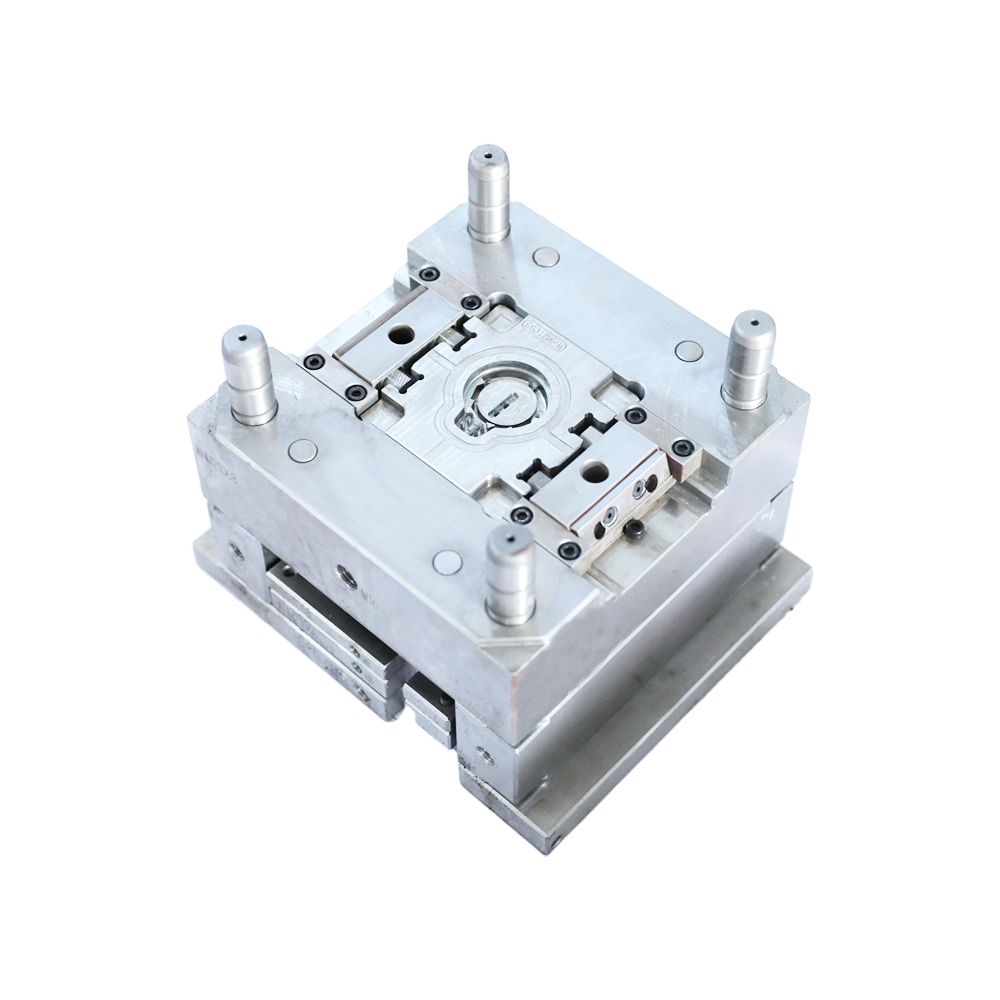

After the mold is closed, the gap between parting surfaces shall be less than the overflow value of the formed plastic, and the parallelism of other template mating surfaces shall be within the range of 0.01~0.02mm; The fitting accuracy of the fixed part is generally within the range of 0.01~0.02mm;

If the small core has no requirements for insertion or has little impact on the size, a clearance fit of 0.01~0.02mm on both sides can be adopted; The fitting accuracy of sliding part is generally H7/e6, H7/f7 and H7/g6.

Note: If there is an insert on the mirror surface that is attached to a step, the fitting should not be too tight, otherwise, when the insert is knocked back from the front, the tool used for knocking is easy to damage the mirror surface. If it does not affect the product size, the bilateral clearance of 0.01~0.02mm can be used for fitting.

+86-15995701933

+86-15995701933 [email protected]

[email protected]- OEM Plastic Mould Manufacturers

��������

��������