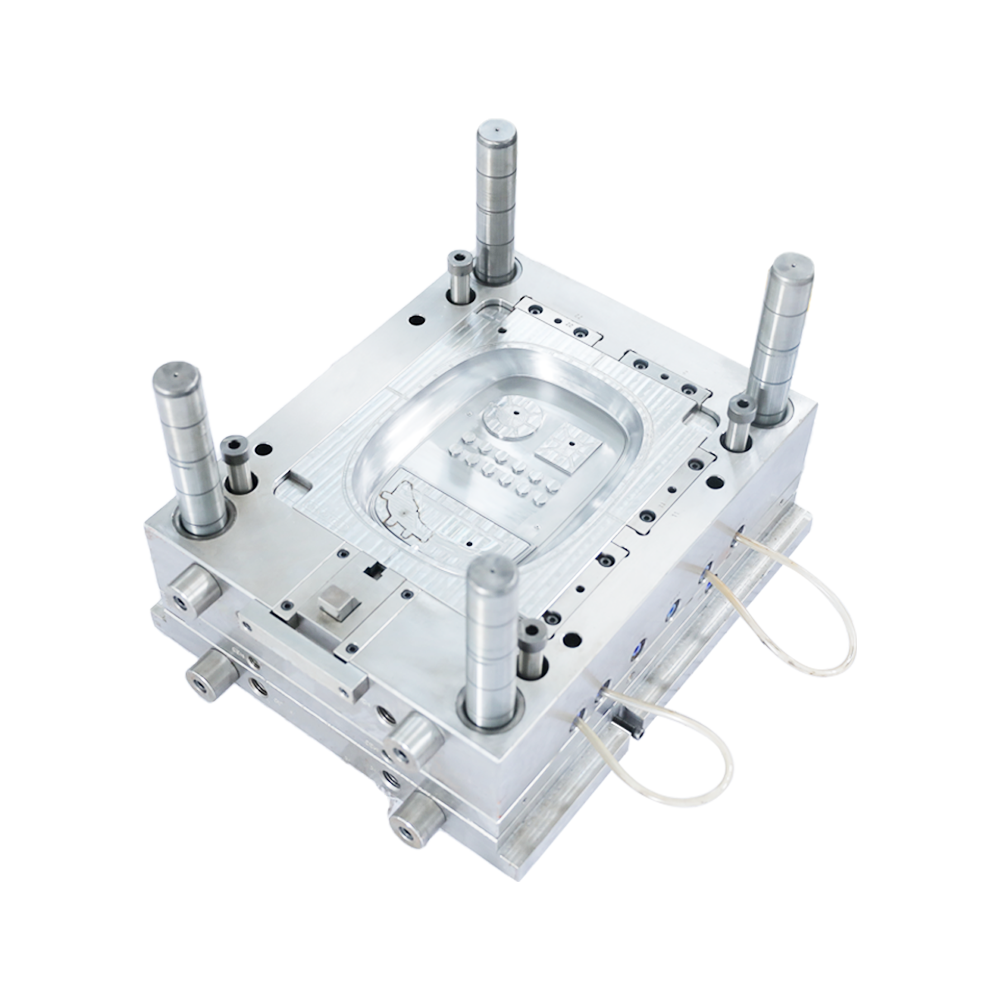

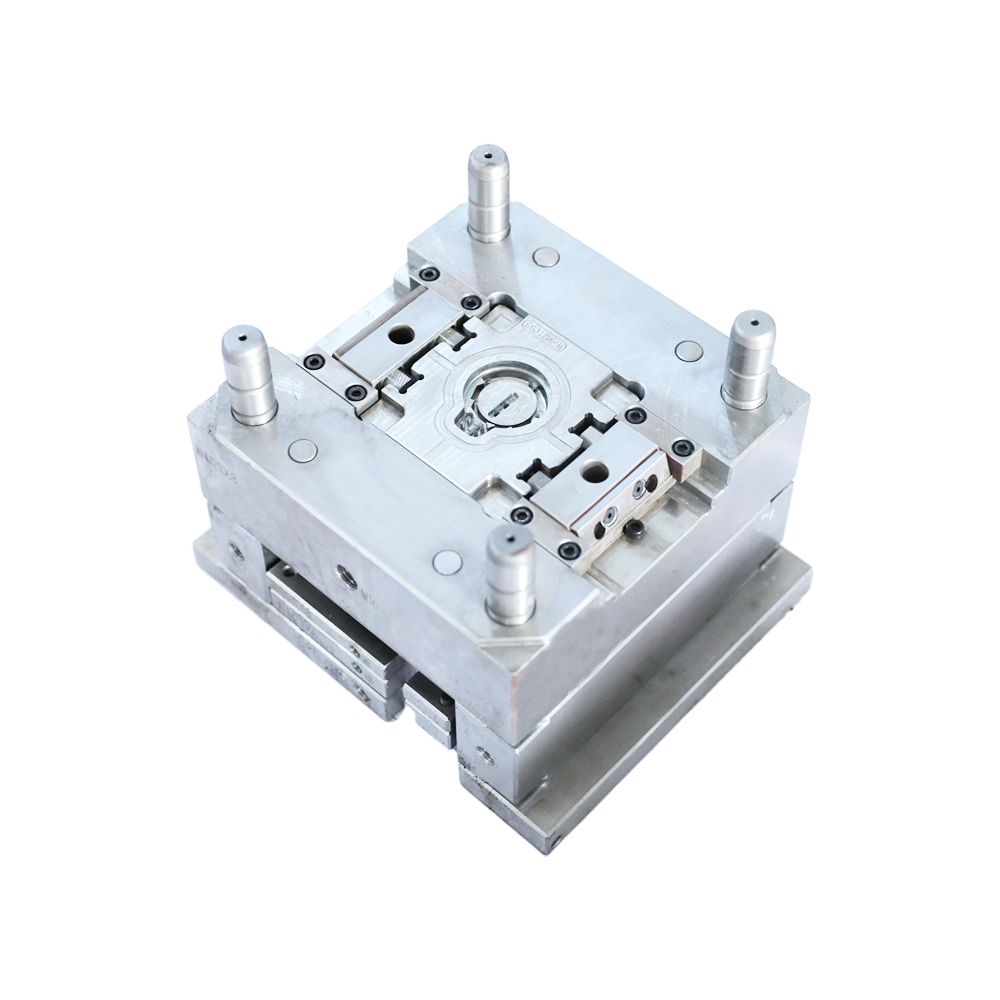

The most important part of the automobile mold is the cover mold. Such dies are mainly cold stamping dies. In a broad sense, "automotive molds" are the general term for molds that manufacture all parts of an automobile. For example, stamping molds, injection molds, forging molds, casting wax molds, glass molds, etc. What are the classification of automobile molds according to the nature of the process?

a. Blanking die: A die that separates materials along a closed or open contour. Such as blanking dies, punching dies, cutting dies, incision dies, trimming dies, cutting dies, etc.

b. Bending die: A die that bends and deforms sheet blanks or other blanks along a straight line (bending line) to obtain a workpiece with a certain angle and shape.

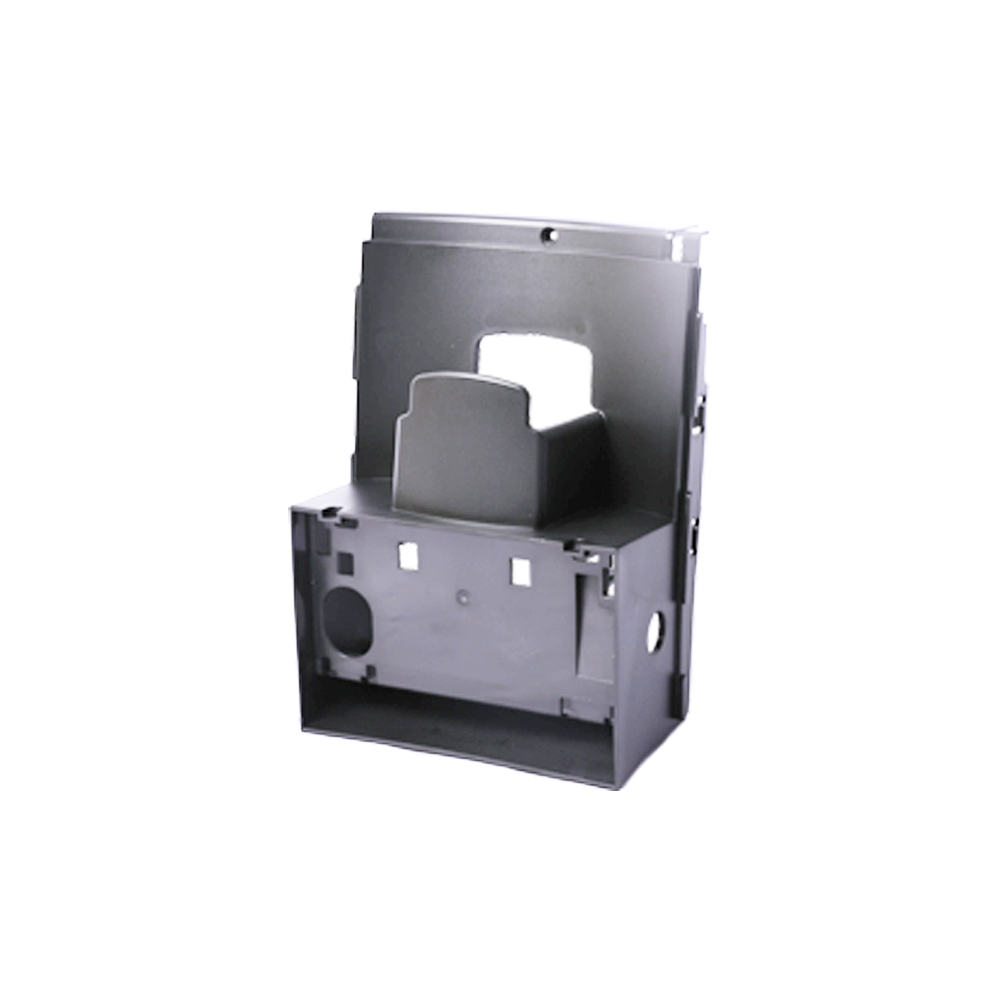

c. Deep drawing die: It is a die that makes the blank of the sheet into an open hollow part, or further changes the shape and size of the hollow part.

d. Forming die: It is a die that directly copies and forms the blank or semi-finished workpiece according to the shape of the convex and concave die, and the material itself only produces local plastic deformation. Such as bulging die, shrinking die, flaring die, undulating forming die, flanging die, shaping die, etc.

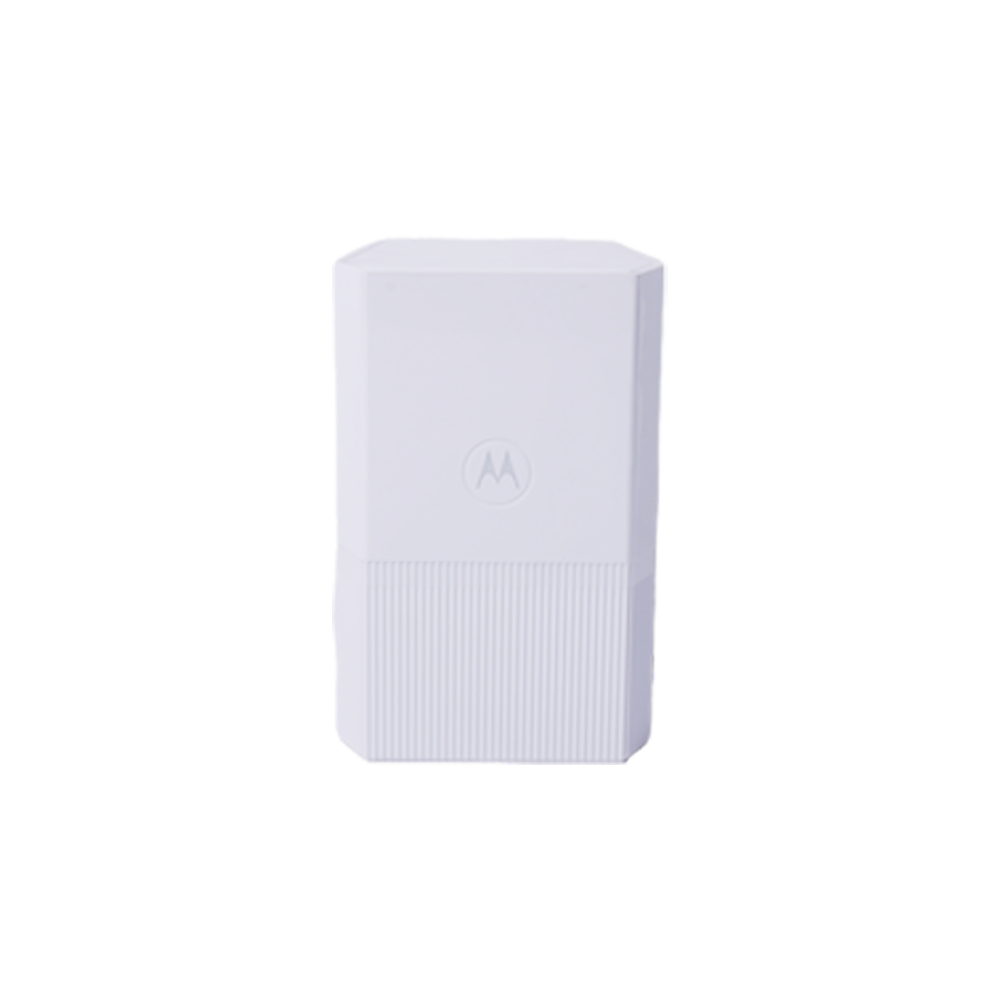

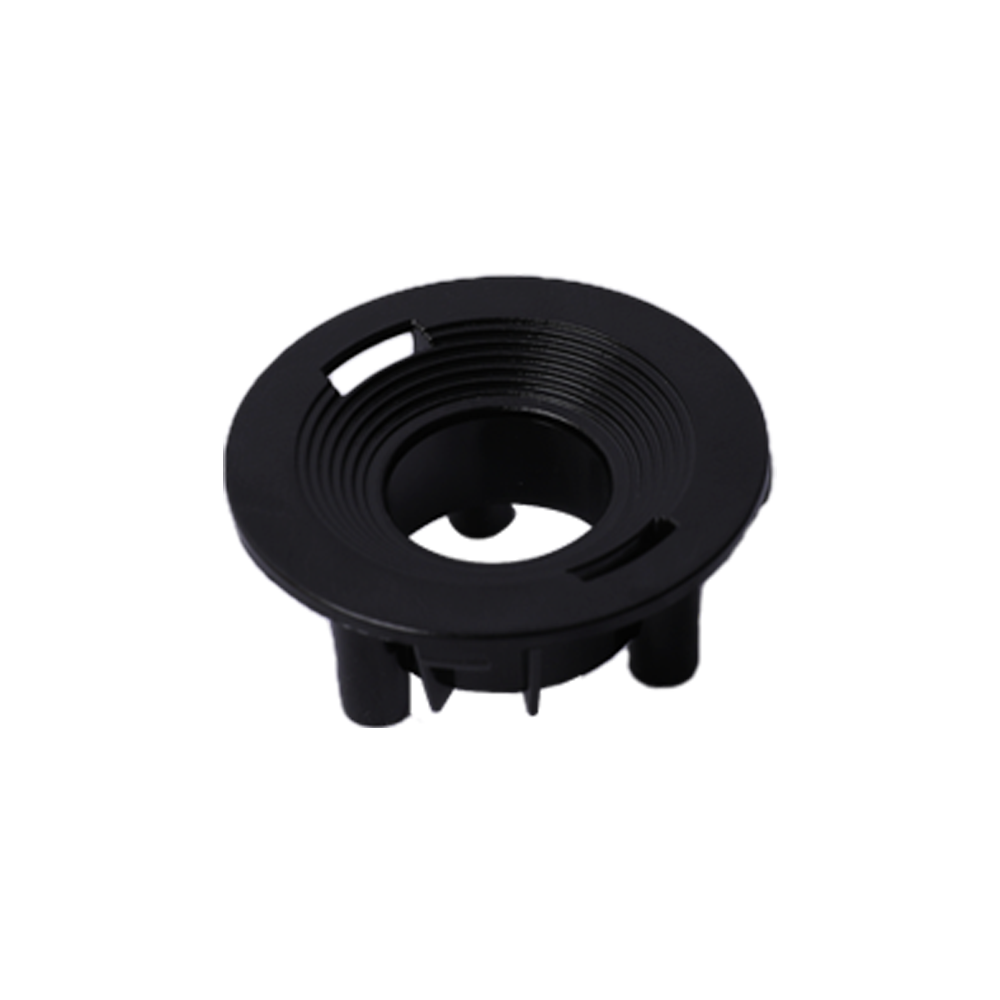

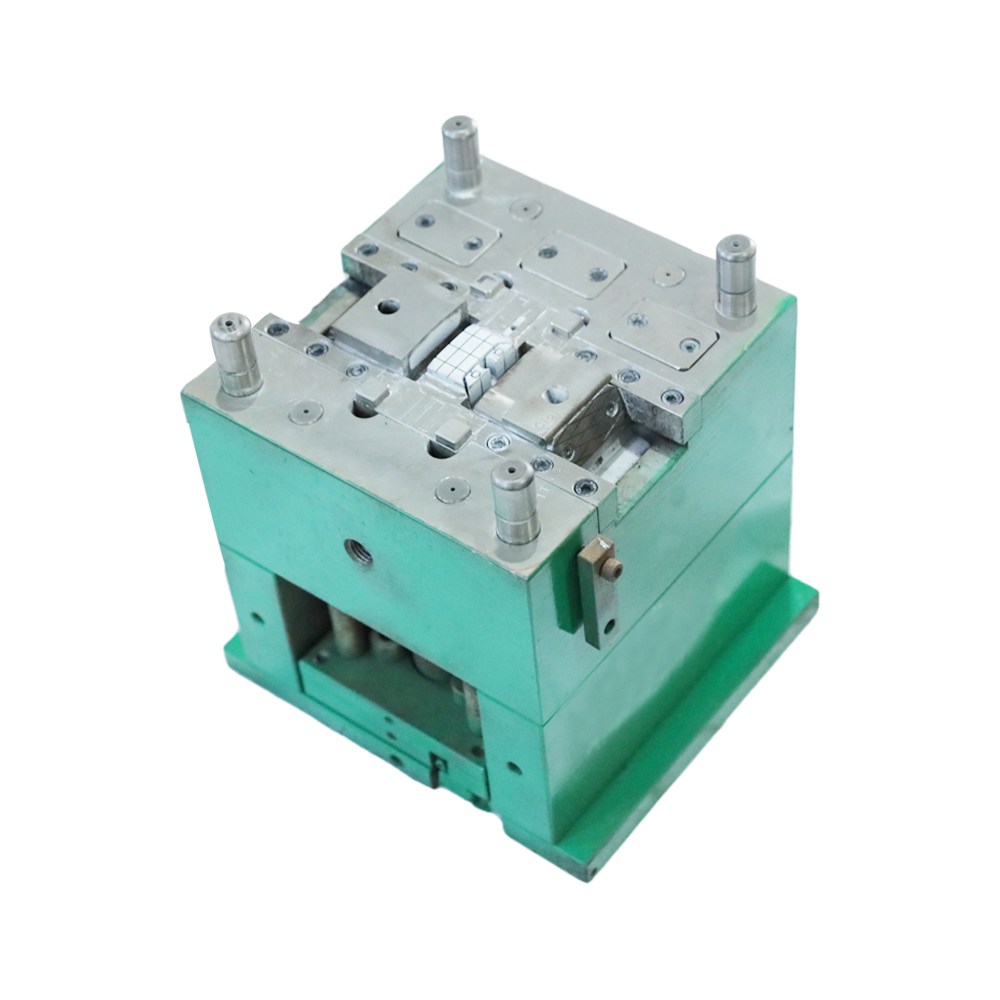

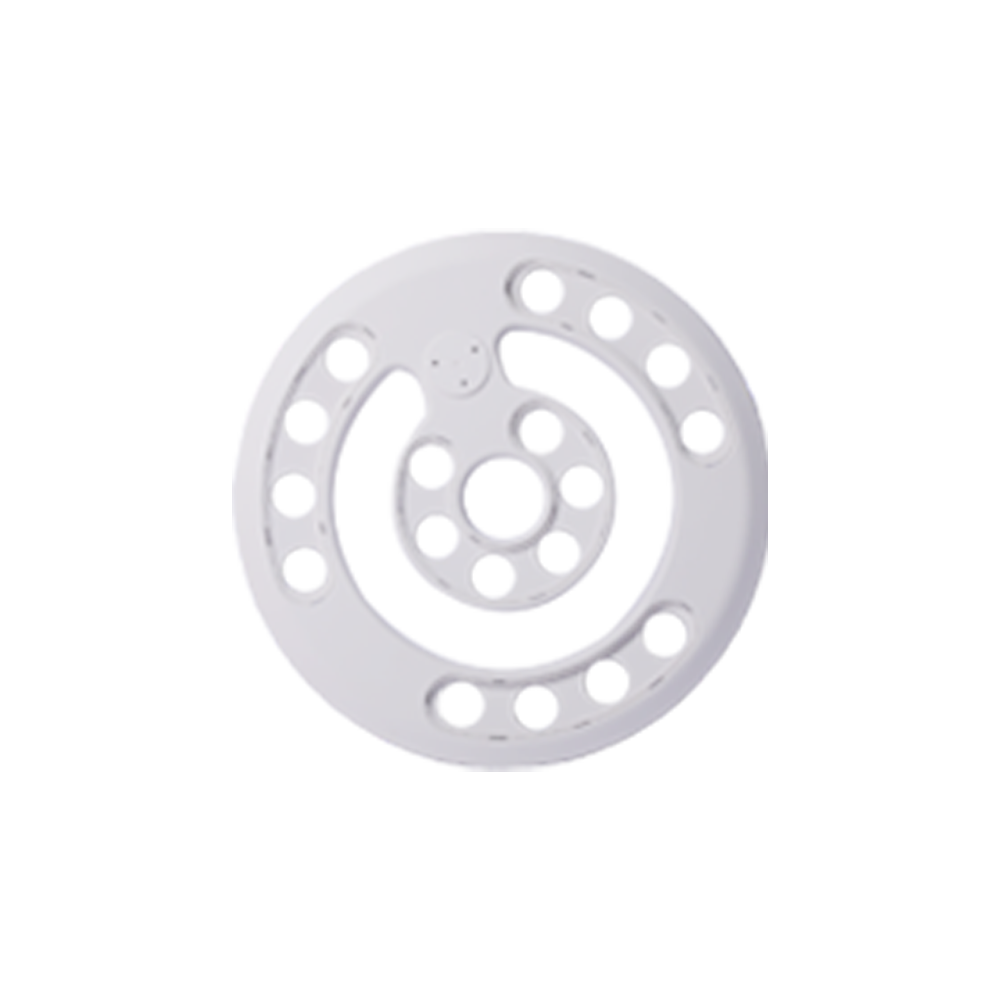

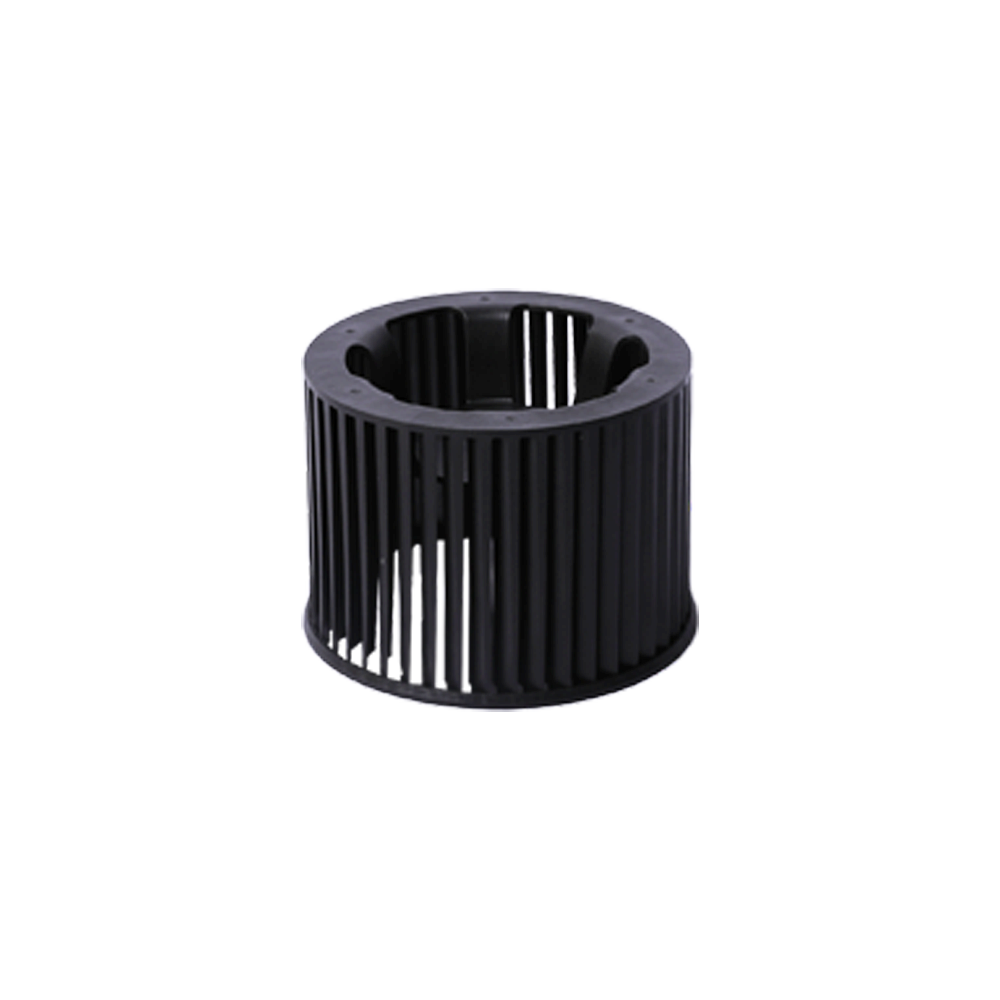

Suzhou Wellhong Electric Co., Ltd. is a professional mould manufacturer. Some moulds are exported to Japan, Europe and the United States. We have the right to import and export the goods. We can develop and manufacture the moulds according to the needs of our customers. We pay attention to quality control, new project development, personnel training, team spirit. In recent years, we have established long-term business relationships with many well-known enterprises at home and abroad.

+86-15995701933

+86-15995701933 [email protected]

[email protected]- OEM Plastic Mould Manufacturers

��������

��������