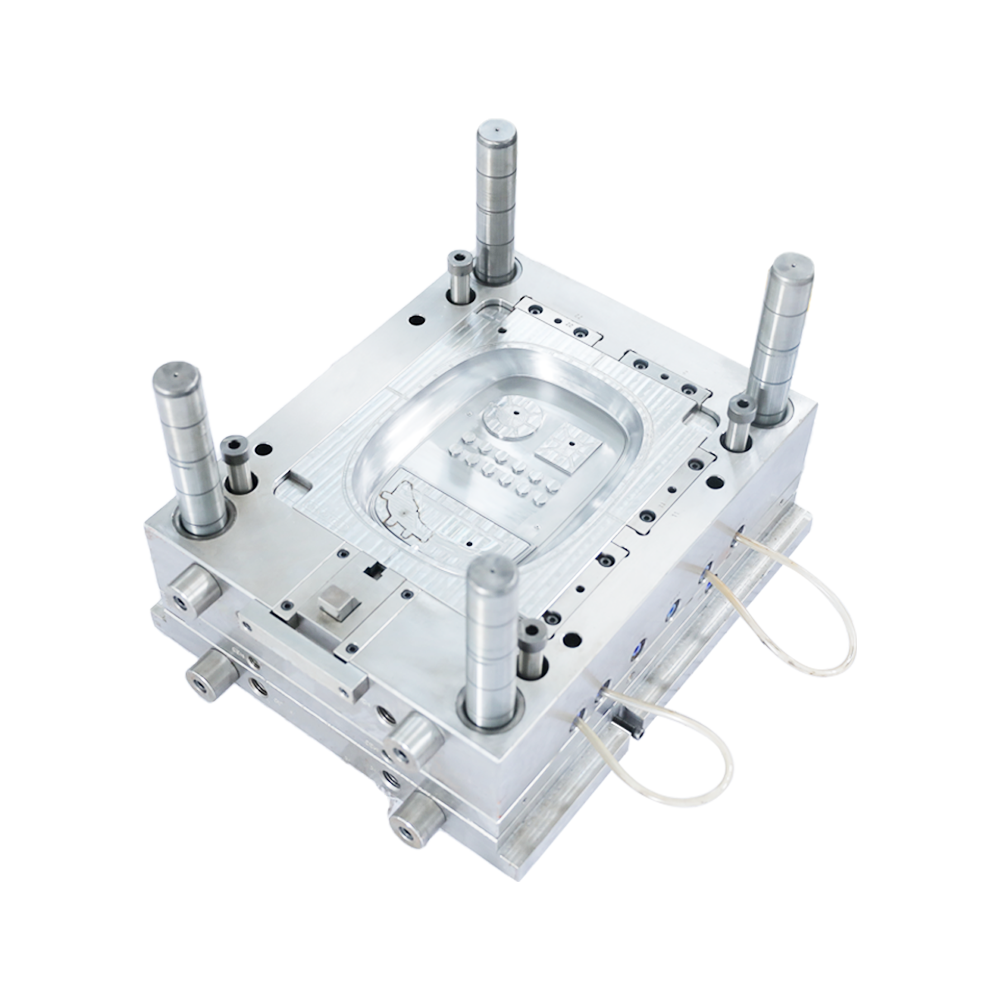

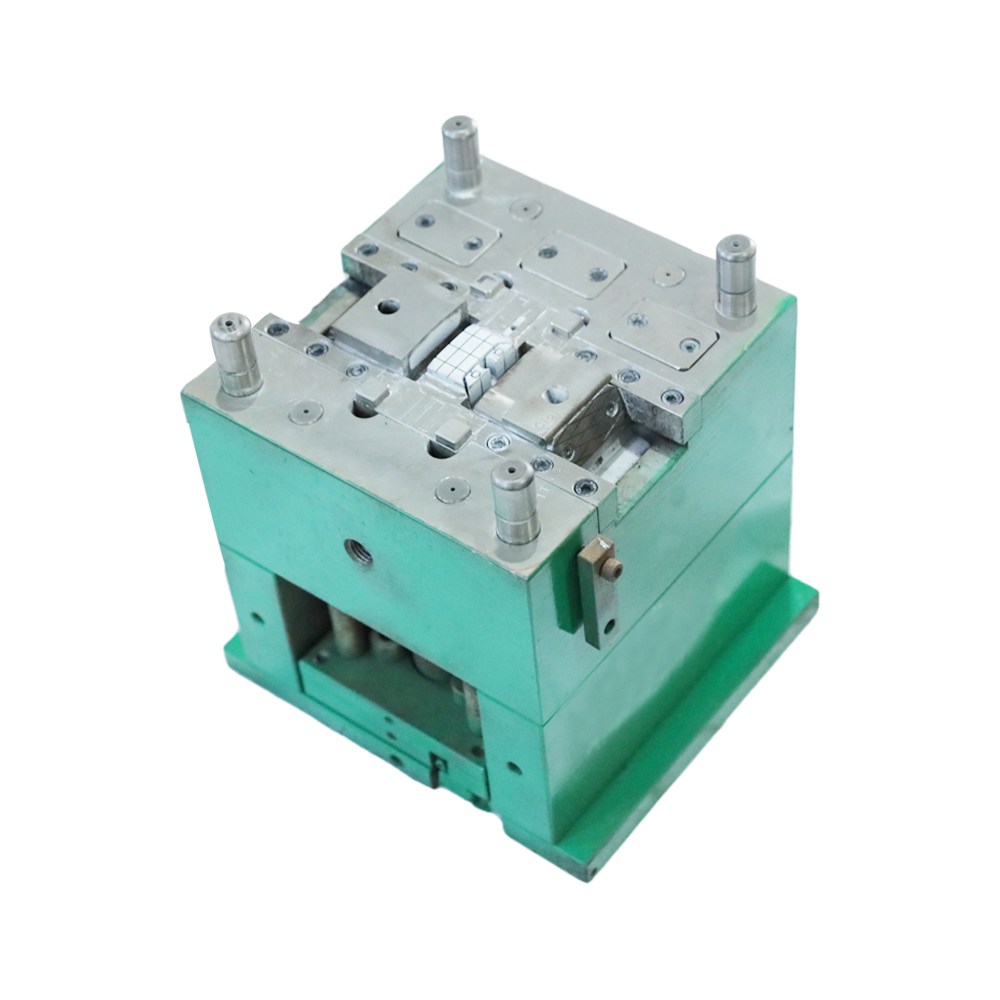

The level of mold technology is an important indicator to measure the level of a country's manufacturing industry. With the further development of my country's industry, the mold industry is required to develop in the direction of large-scale, precise, efficient and multi-functional. One of the important ways is to combine mold and automation. .

The key to the development of stamping dies is die manufacturing technology, die materials and die talents. The development of die technology is a key factor in the development of die industry. Its development goal is to meet the requirements of short delivery time, high precision, good quality and low price of die products. , One of the important directions is to vigorously develop mold automation.

The automation development related to stamping dies is to combine traditional dies with opto-electromechanical technology, integrate multi-process automation modules into the dies, and realize full continuous die production through electrical control, thereby saving a lot of machines and manpower and maximizing efficiency. Process optimization, maximize benefits.

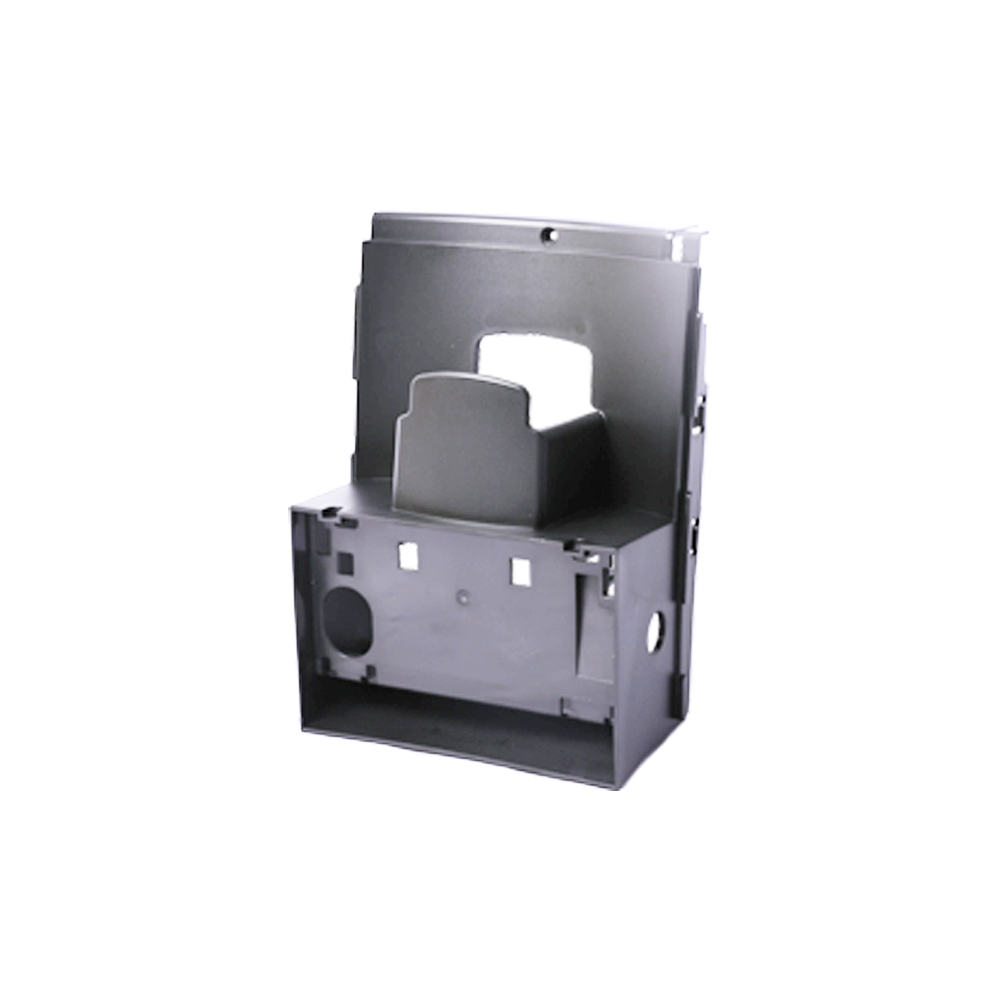

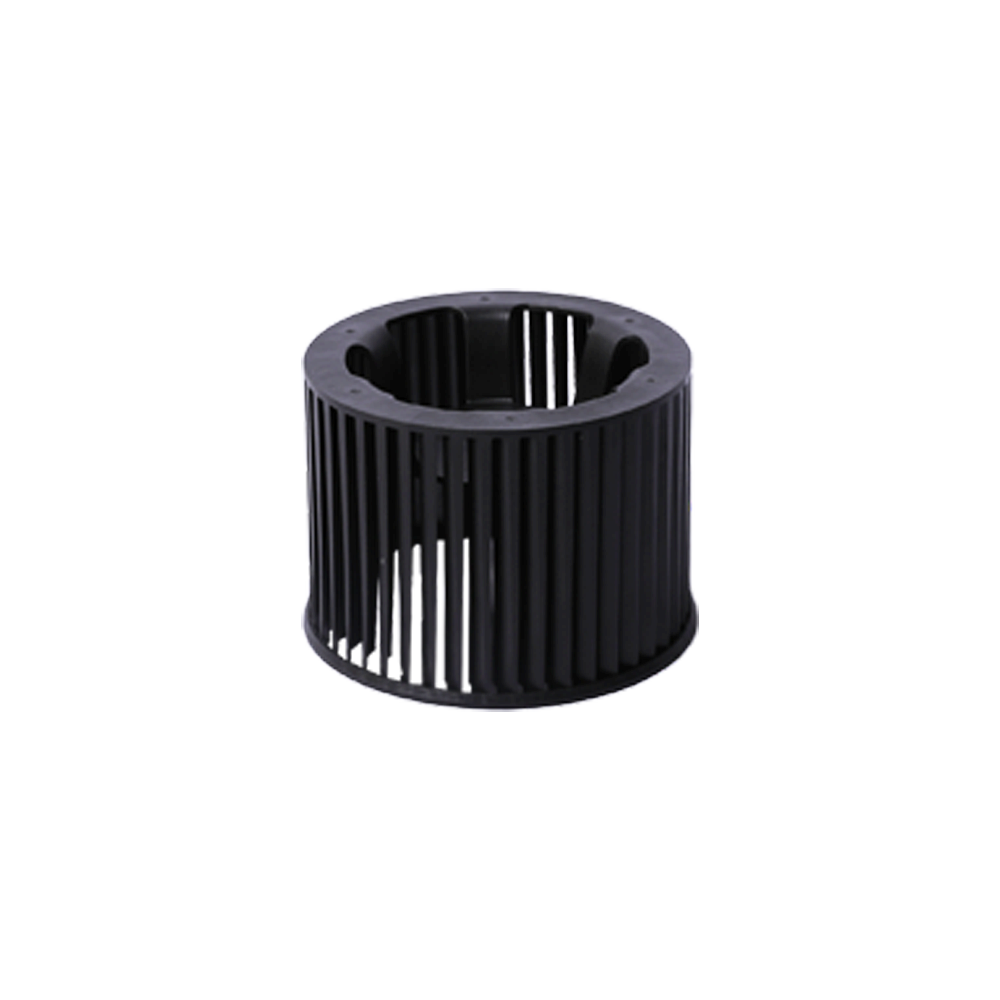

Stamping refers to the process of installing a mold on a punching machine and passing a plate-shaped material between the molds, the stamping force deforms, cuts, bends, and forms the material. The stamping processes that can realize automatic processing include: hardware riveting, tapping Wire, self-riveting and mutual-riveting products, and integrated production of small components.

The stamping process is widely used in the market because of its good interchangeability, material saving, and parts with thin walls, light weight, good rigidity, high surface quality and complex shapes that are difficult to manufacture by other processing methods. The production of stamping dies is manual, which greatly restricts its development.

+86-15995701933

+86-15995701933 [email protected]

[email protected]- OEM Plastic Mould Manufacturers

��������

��������