Other classifications of molds

(1) Hot runner mold

With the help of the heating device, the plastic in the gating system will not solidify, nor will it be demolded with the product, so it is also called a runnerless mold. Advantages: 1) No waste 2) Can reduce injection pressure, can use multi-cavity mold 3) Can shorten molding cycle 4) Improve product quality Features suitable for hot runner molding compounds: 5) The melting temperature range of plastics is wide. At low temperature, it has good fluidity, and at high temperature, it has better thermal stability. 6) Sensitive to pressure, does not flow without pressure, but can flow when pressure is applied. 7) Good specific heat, so that it can be cooled quickly in the mold. Available hot runner plastics are PE, ABS, POM, PC, HIPS, PS. There are two commonly used hot runners: 1) heating runner molds 2) adiabatic runner molds.

(2) Hard mold

The steel plate used in the inner mold needs to be heat treated after buying it, such as quenching and carburizing, to meet the requirements of use. Such an injection mold is called a hard mold. For example, the inner mold is made of H13 steel, 420 steel, and S7 steel.

(3) Soft mold (below 44HRC)

The steel used in the inner mold can meet the requirements of use without heat treatment after purchase. Such injection molding is called soft mold. For example, the inner module adopts P20 steel, ace steel, 420 steel, NAK80, aluminum, beryllium copper.

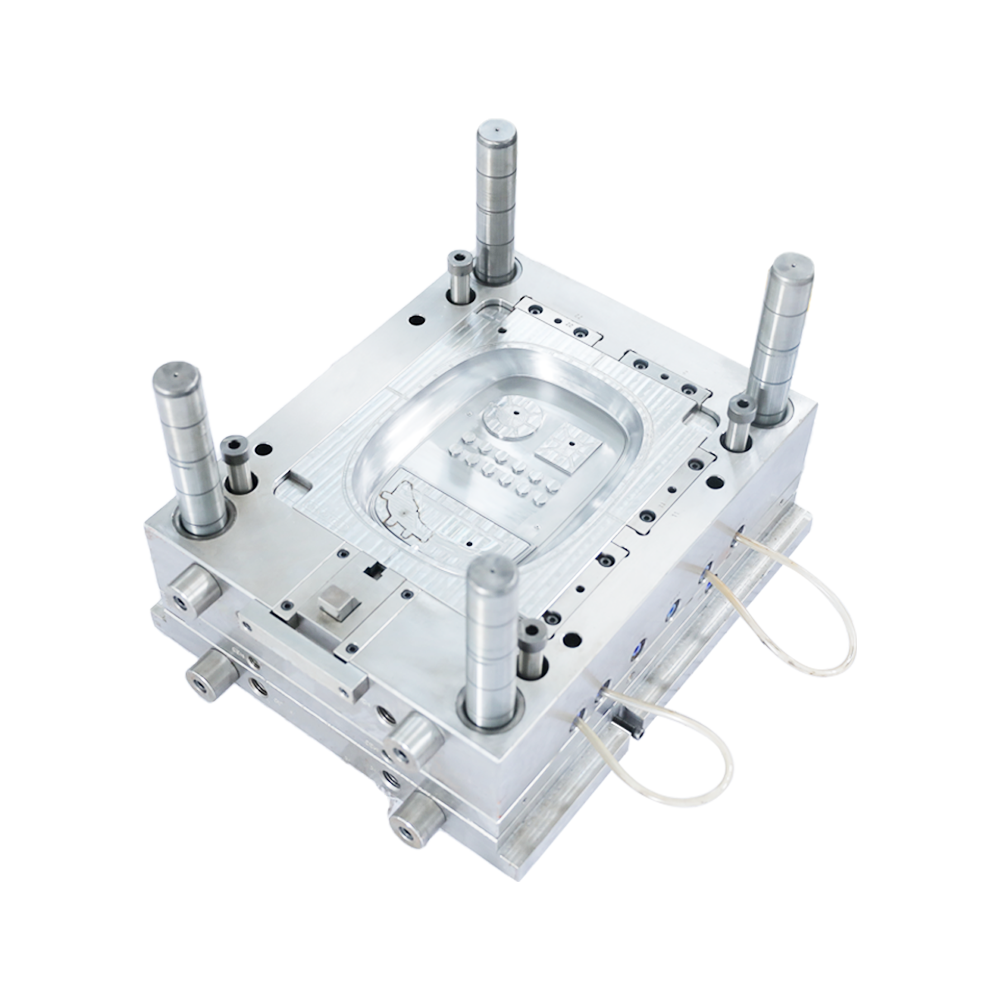

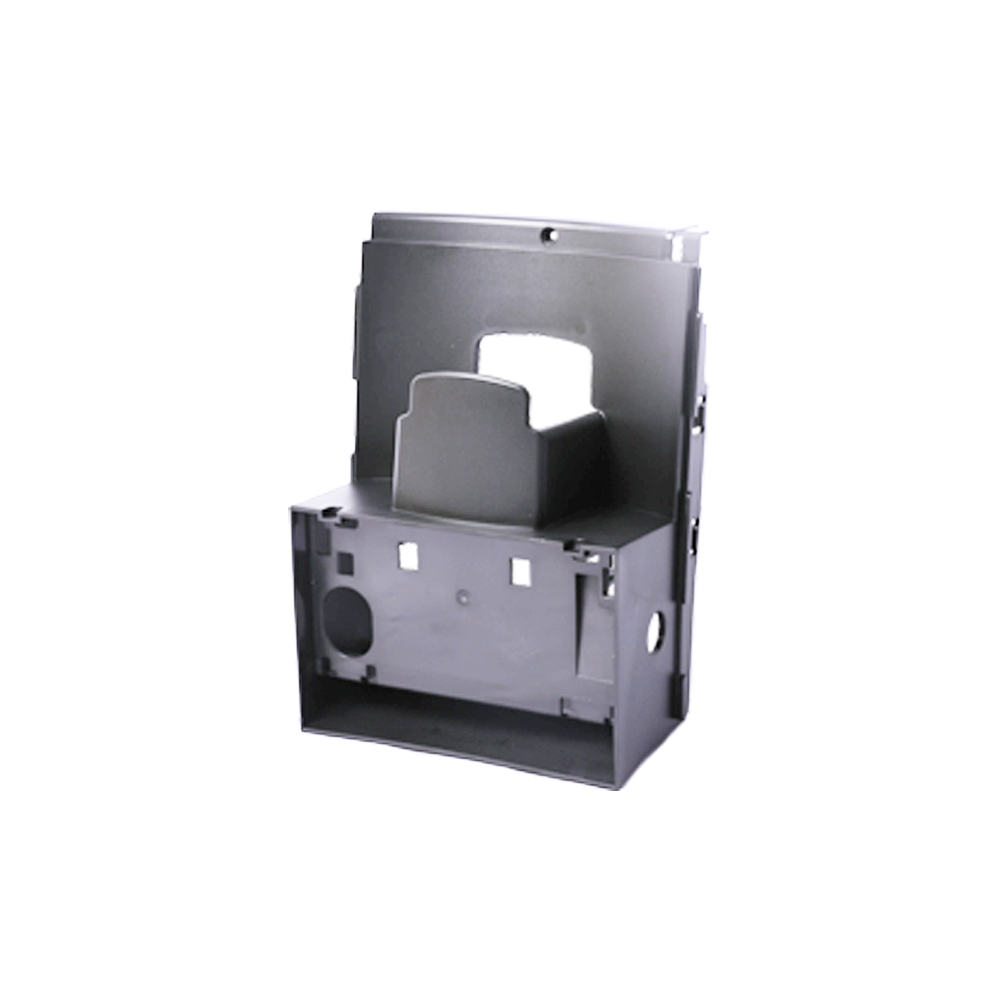

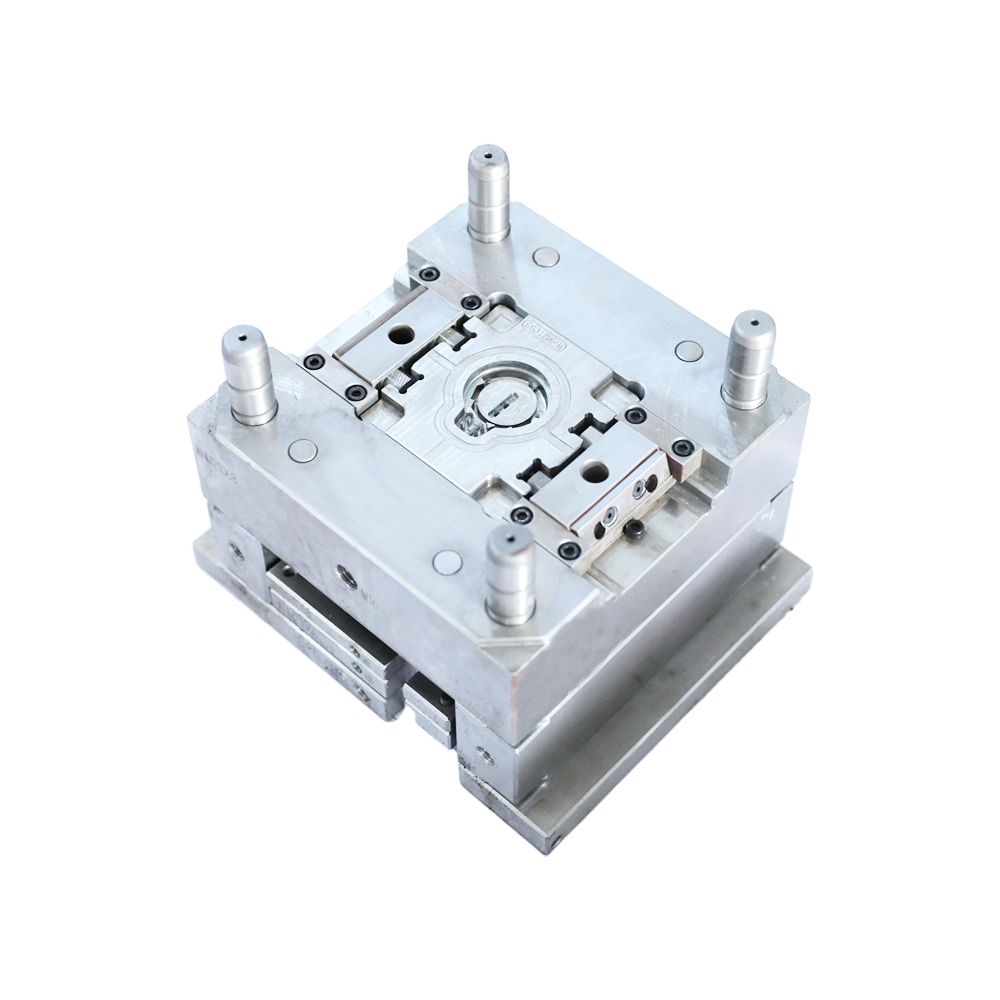

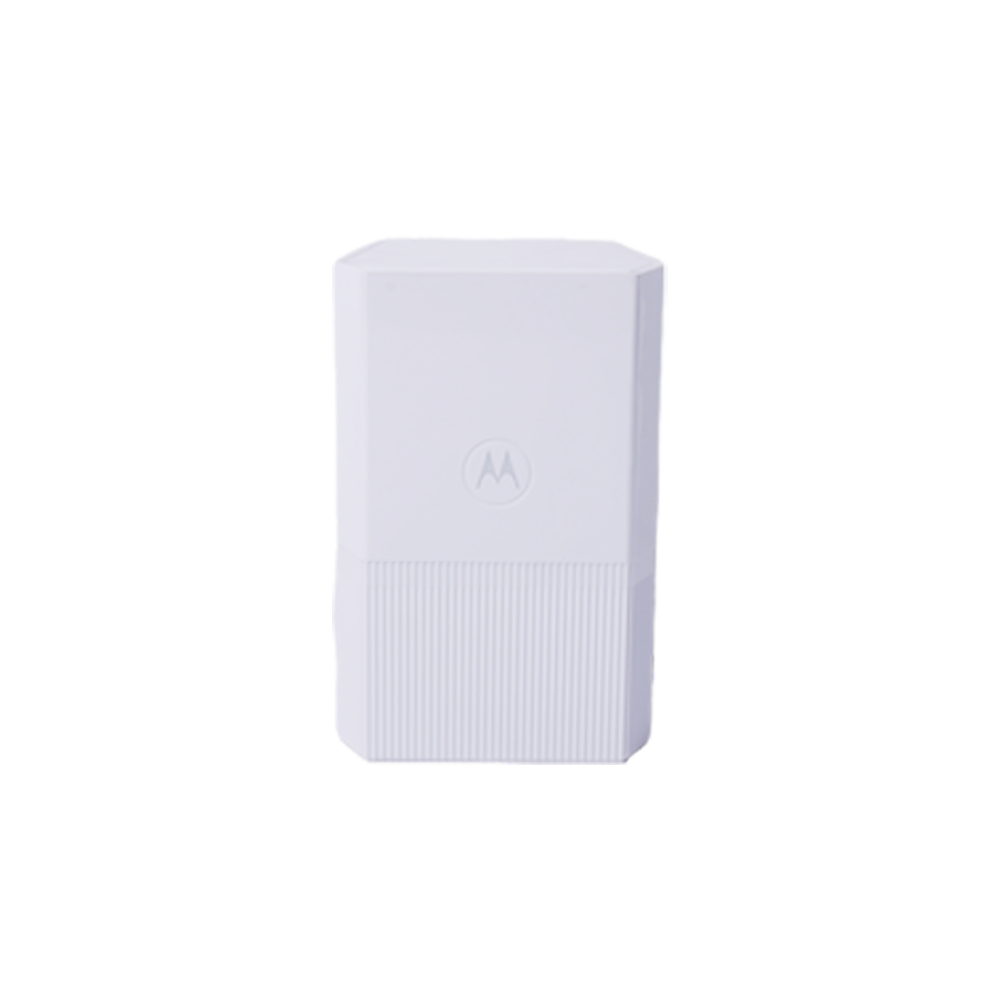

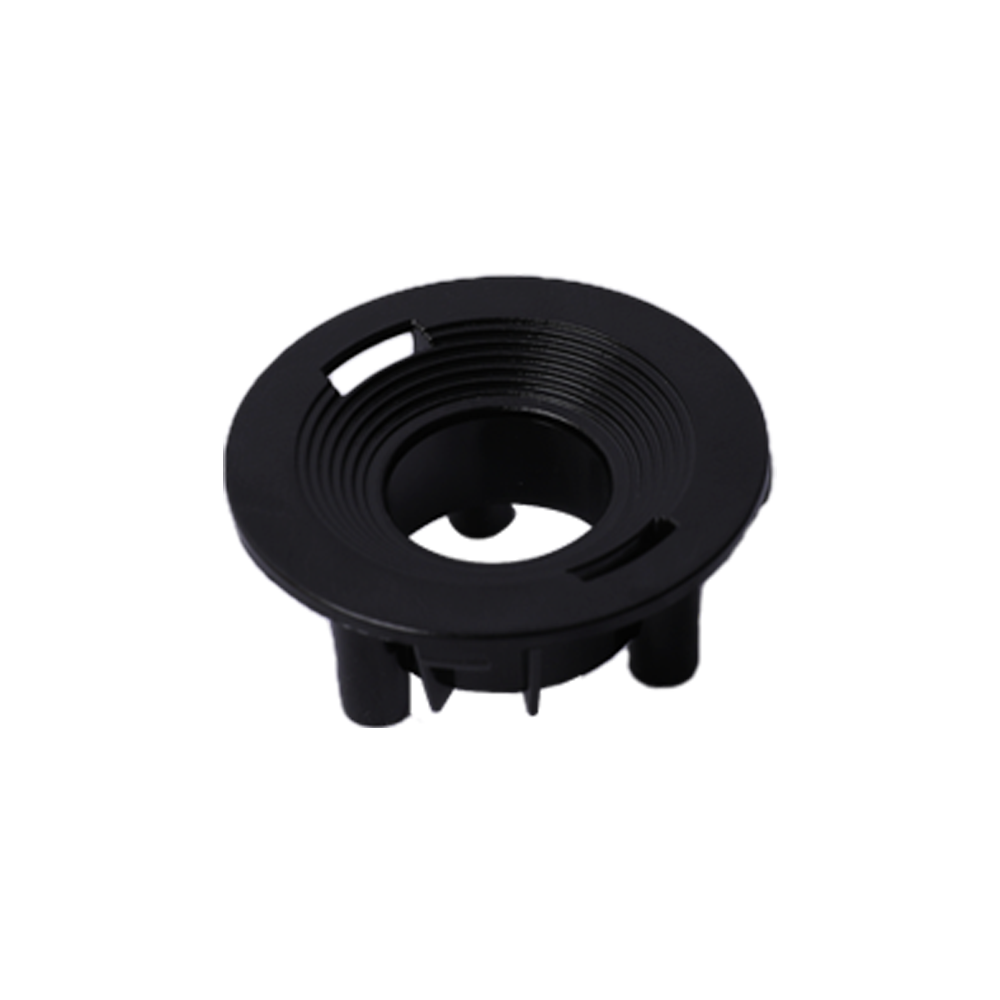

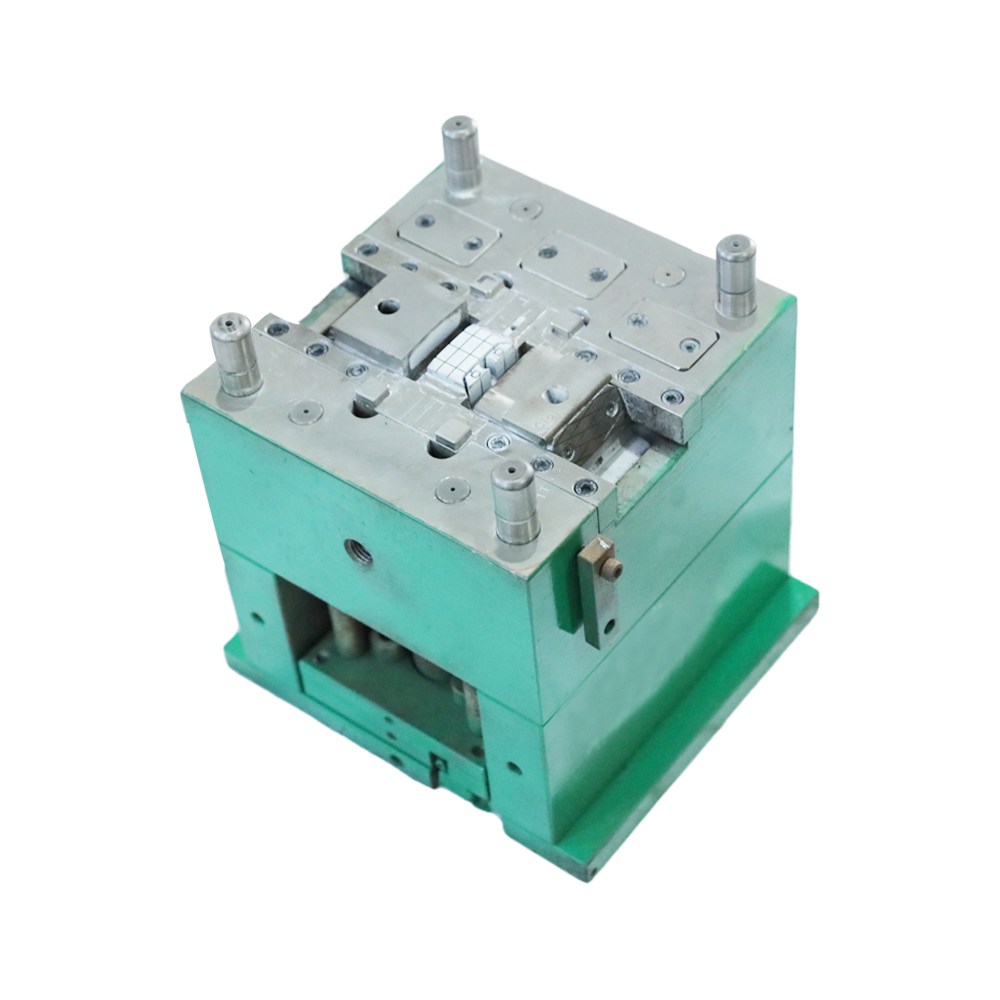

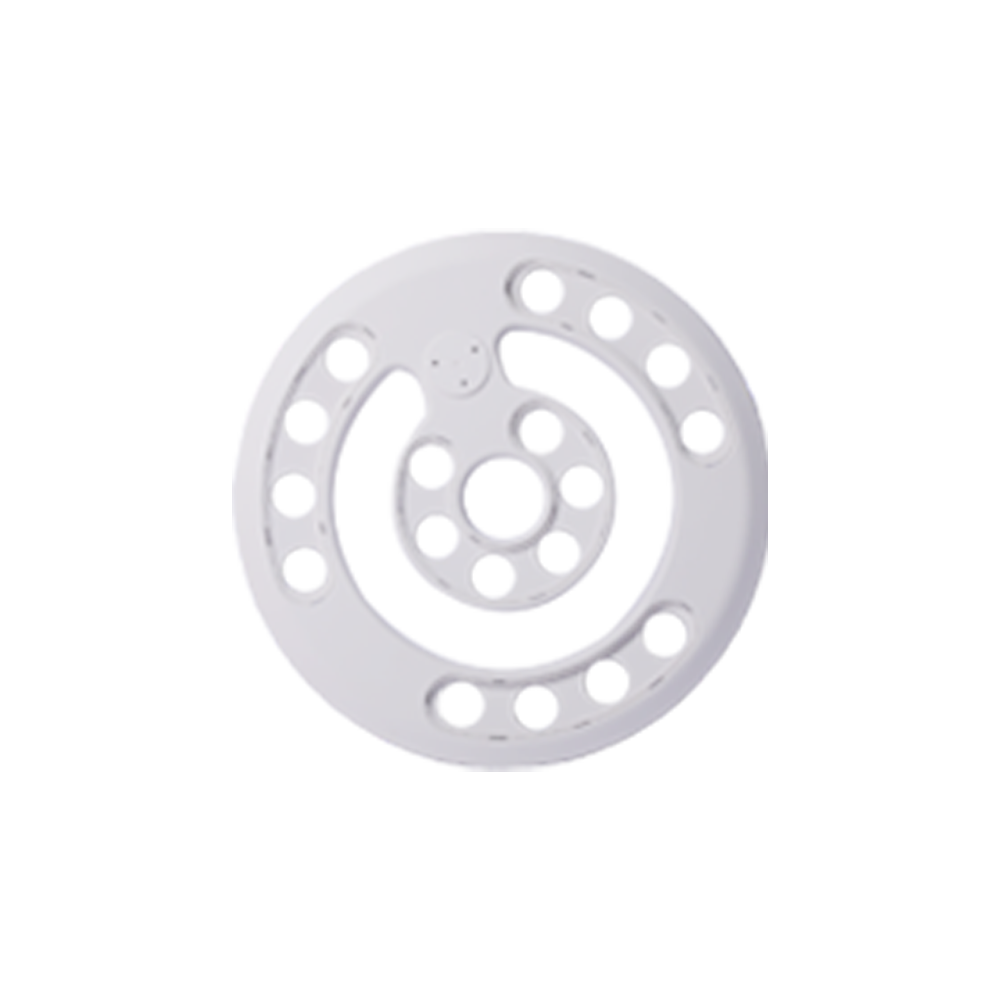

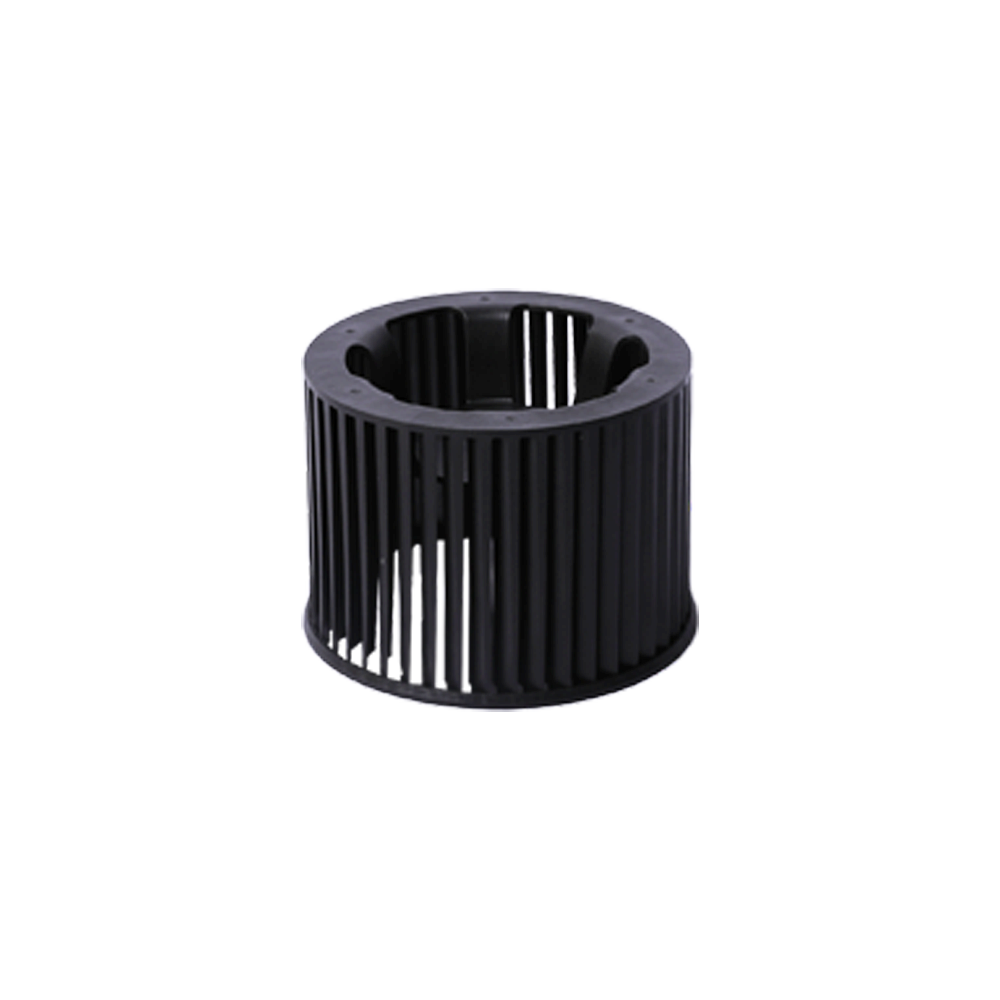

Suzhou Huihong Electric Co., Ltd. is a professional manufacturer of precision molds , injection molding, assembling and silk-printing. Some moulds are exported to Japan, Europe and the United States. We have the right to import and export the goods. We can develop and manufacture the moulds according to the needs of our customers. We pay attention to quality control, new project development, personnel training, team spirit. In recent years, we have established long-term business relationships with many well-known enterprises at home and abroad.

��������

��������