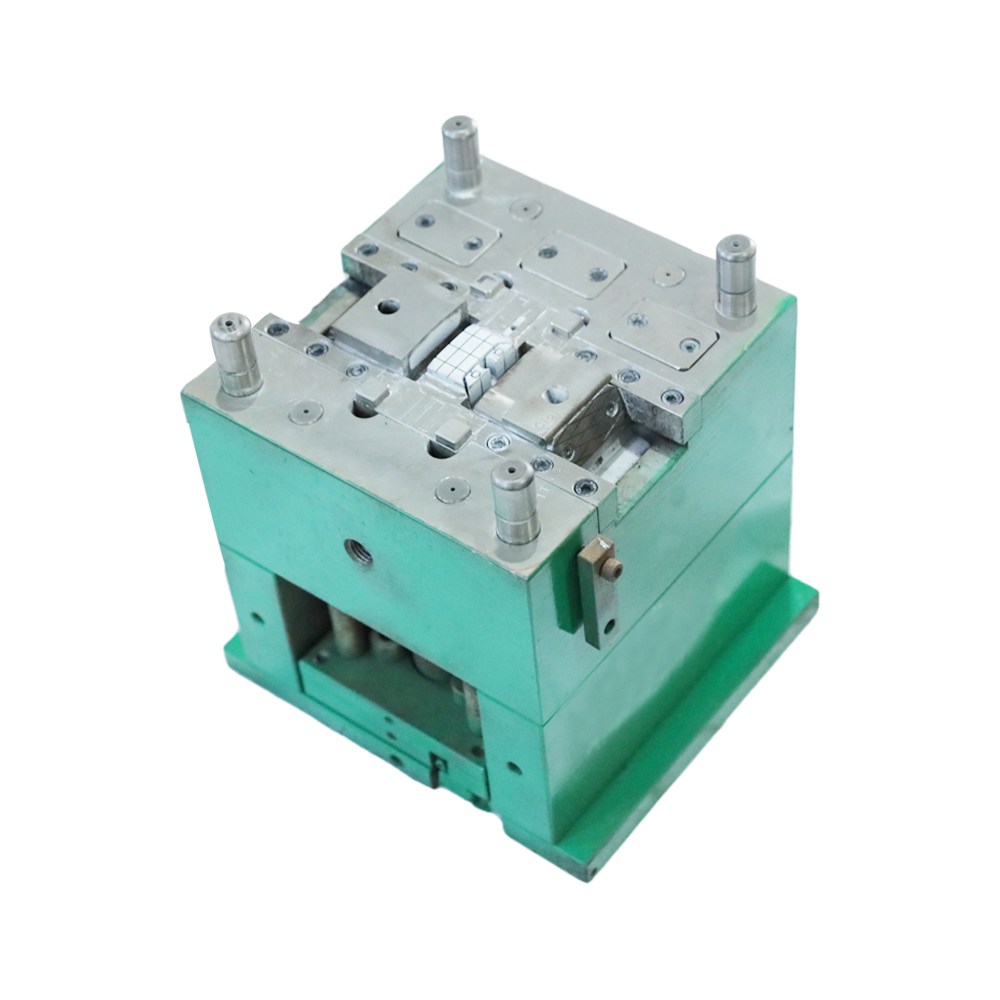

Mould material and gating system

The most important factors of mold material are thermal strength and thermal stability, commonly used mold materials: working temperature, forming material, mold material

<300℃ zinc alloy Cr12, Cr12MoV, S-136, SLD, NAK80, GCr15, T8, T10.

300~500℃ aluminum alloy, copper alloy 5CrMnMo, 3Cr2W8, 9CrSi, W18Cr4V, 5CrNiMo, W6Mo5Cr4V2, M2.

500~800℃ Aluminum alloy, copper alloy, steel titanium GH130, GH33, GH37.

800~1000℃ Titanium alloy, steel, stainless steel, nickel alloy K3, K5, K17, K19, GH99, IN100, ЖC-6NX88, MAR-M200, TRW-NASA, WA.

>1000℃ Nickel alloy Copper base alloy mold, cemented carbide mold.

Gating system classification

According to the different types of gating systems, plastic molds can be divided into three categories:

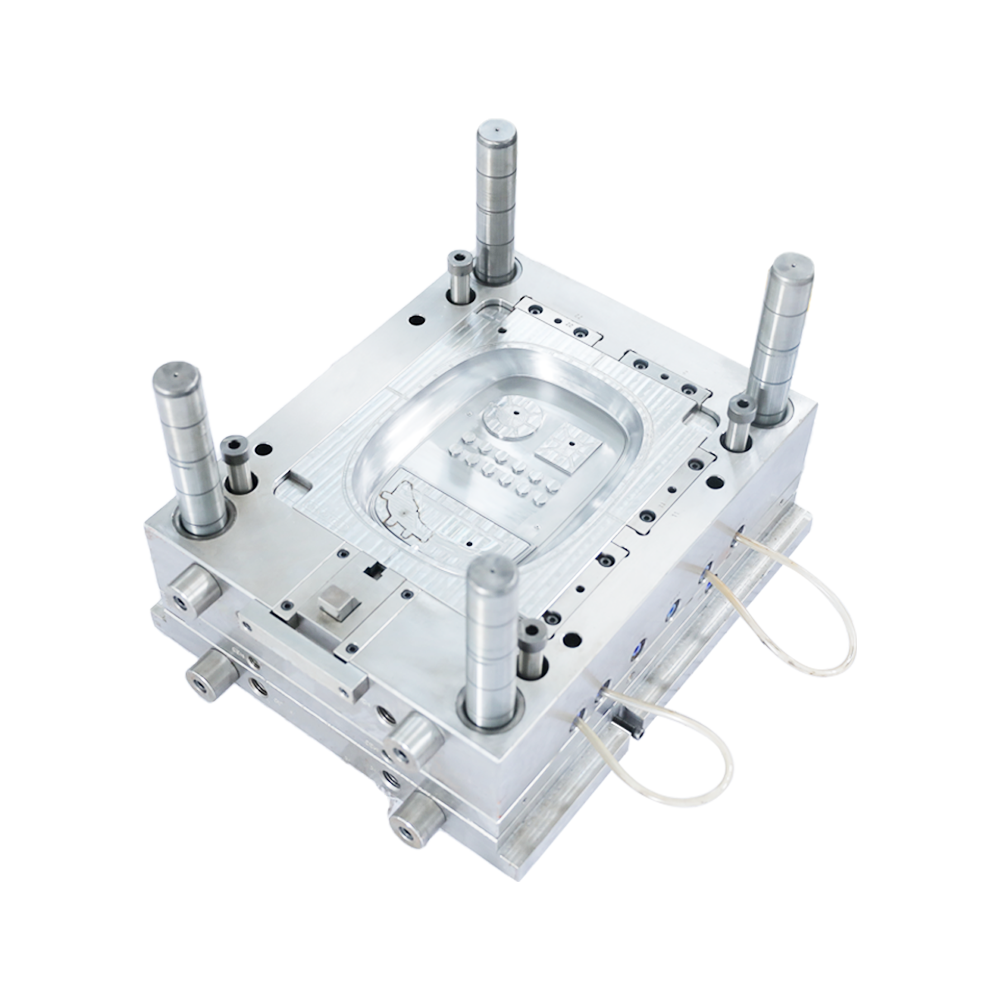

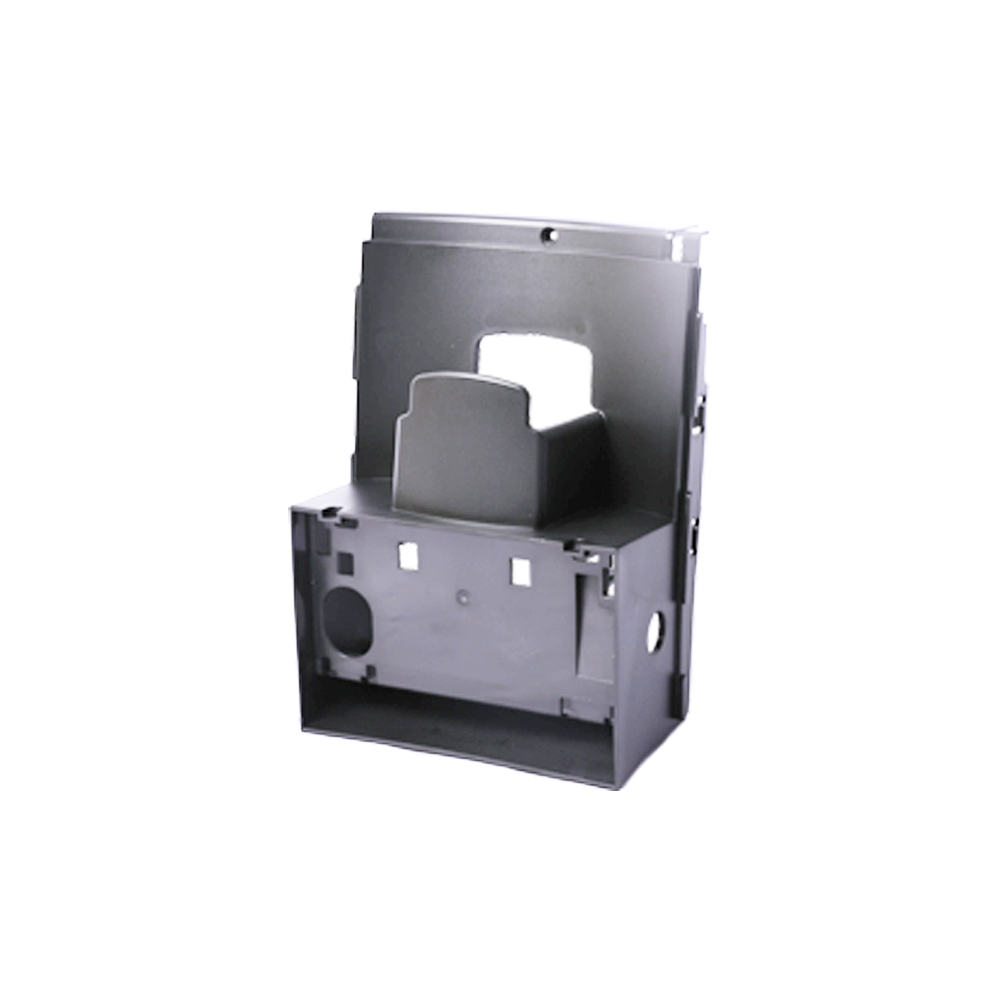

(1) Large nozzle mold: The runner and gate are on the parting line, and the mold is released together with the product when the mold is opened. The design is the simplest, easy to process, and the cost is low, so many people use the large nozzle system for operation. The plastic mold structure is divided into two parts: the movable mold and the fixed mold. The movable part of the injection machine is the movable mold (mostly the ejection side), and the inactive part at the injection end of the injection machine is generally called the fixed mold. Because the fixed part of the large nozzle mold is generally composed of two steel plates, it is also called a two-plate mold for this type of structural mold. The two-plate mold is the simplest structure in the large nozzle mold.

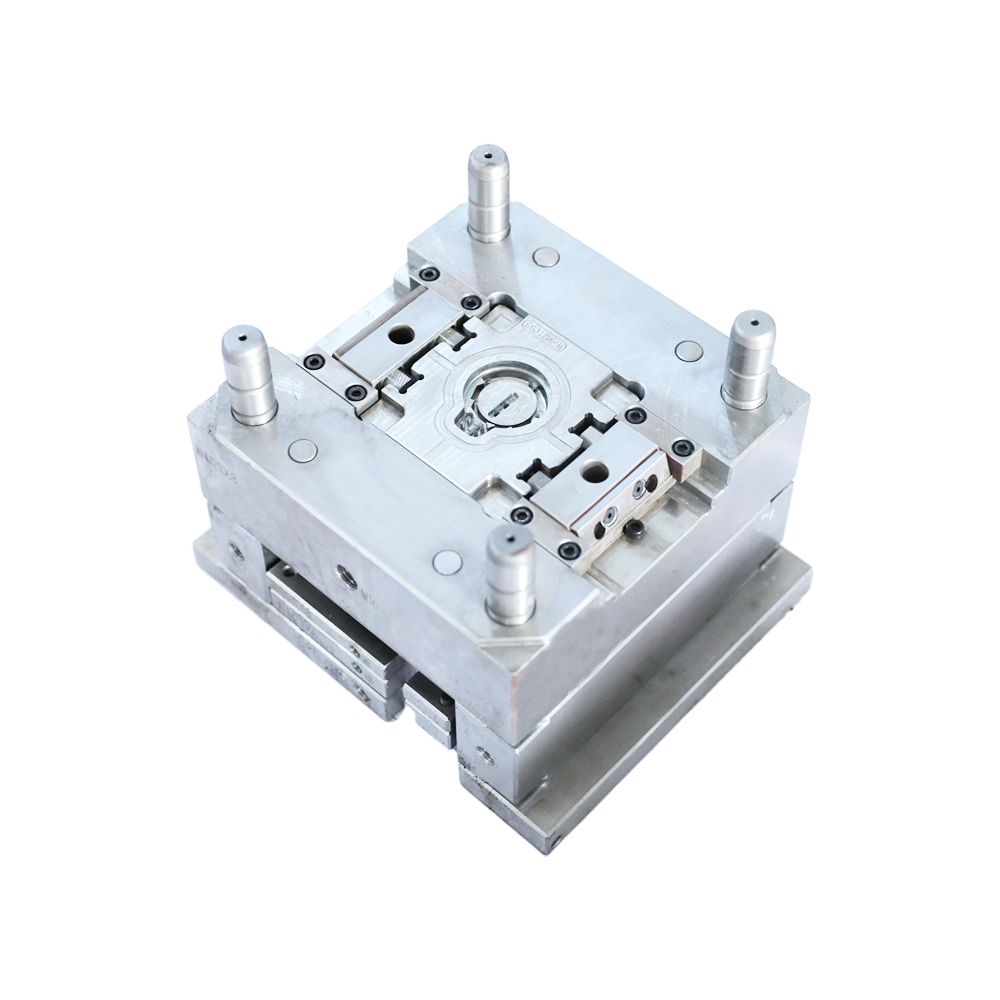

(2) Small nozzle mold: The runner and gate are not on the parting line, and are generally directly on the product. Therefore, it is necessary to design more than one set of nozzle parting lines. The design is more complicated and the processing is more difficult. Generally, it should be selected according to the product requirements. Fine water system. The fixed part of the nozzle mold is generally composed of three steel plates, so this kind of structural mold is also called "three-plate mold". The three-plate mold is the simplest structure in the nozzle mold.

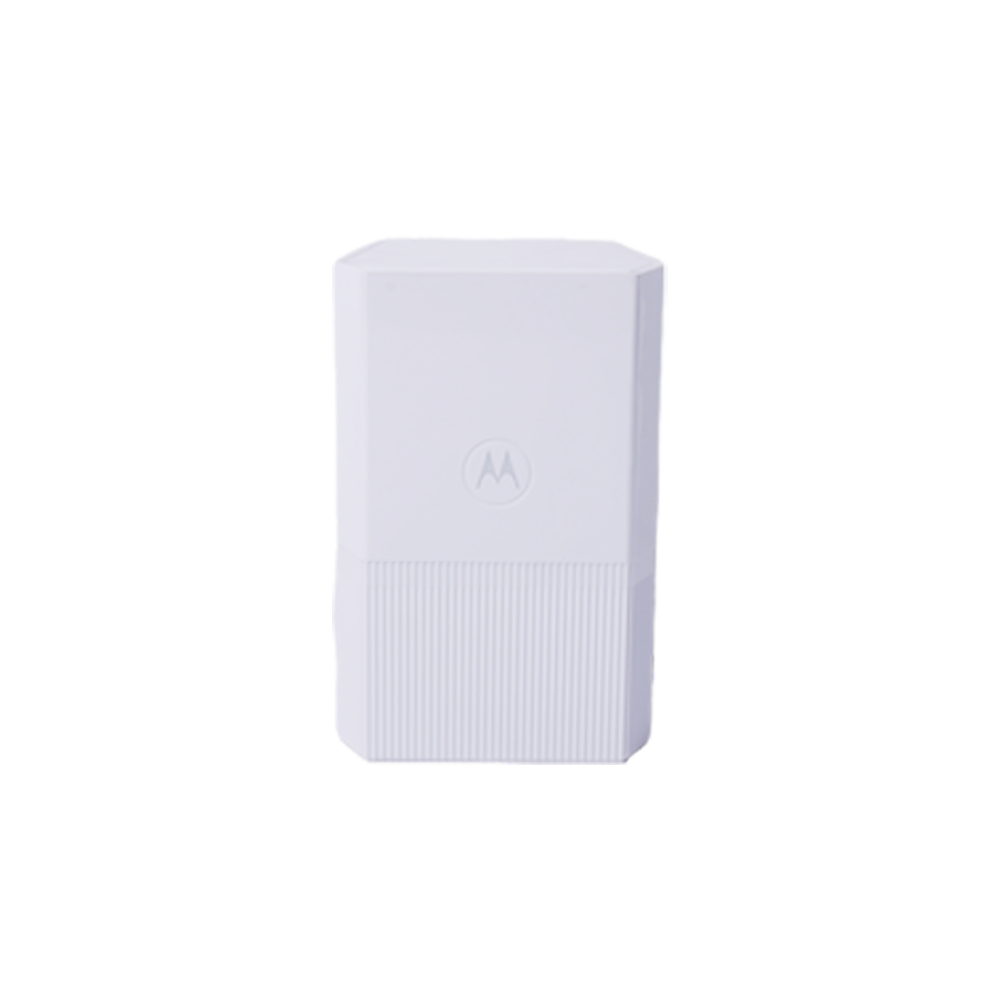

(3) Hot runner mold: The structure of this type of mold is basically the same as that of the fine nozzle. The biggest difference is that the runner is located in one or more hot runner plates and hot nozzles with constant temperature, and there is no cold material demoulding, runner and pouring. The mouth is directly on the product, so the runner does not need to be demolded. This system is also called a nozzleless system, which can save raw materials. It is suitable for the situation where the raw materials are expensive and the product requirements are high, the design and processing are difficult, and the mold cost is high. Hot runner system, also known as hot runner system, is mainly composed of hot sprue sleeve, hot runner plate and temperature control electric box. Our common hot runner system has two types of single-point hot gate and multi-point hot gate. Single-point hot gate is to use a single hot gate sleeve to directly inject molten plastic into the cavity, it is suitable for plastic with a single cavity and a single gate.

+86-15995701933

+86-15995701933 [email protected]

[email protected]- OEM Plastic Mould Manufacturers

��������

��������