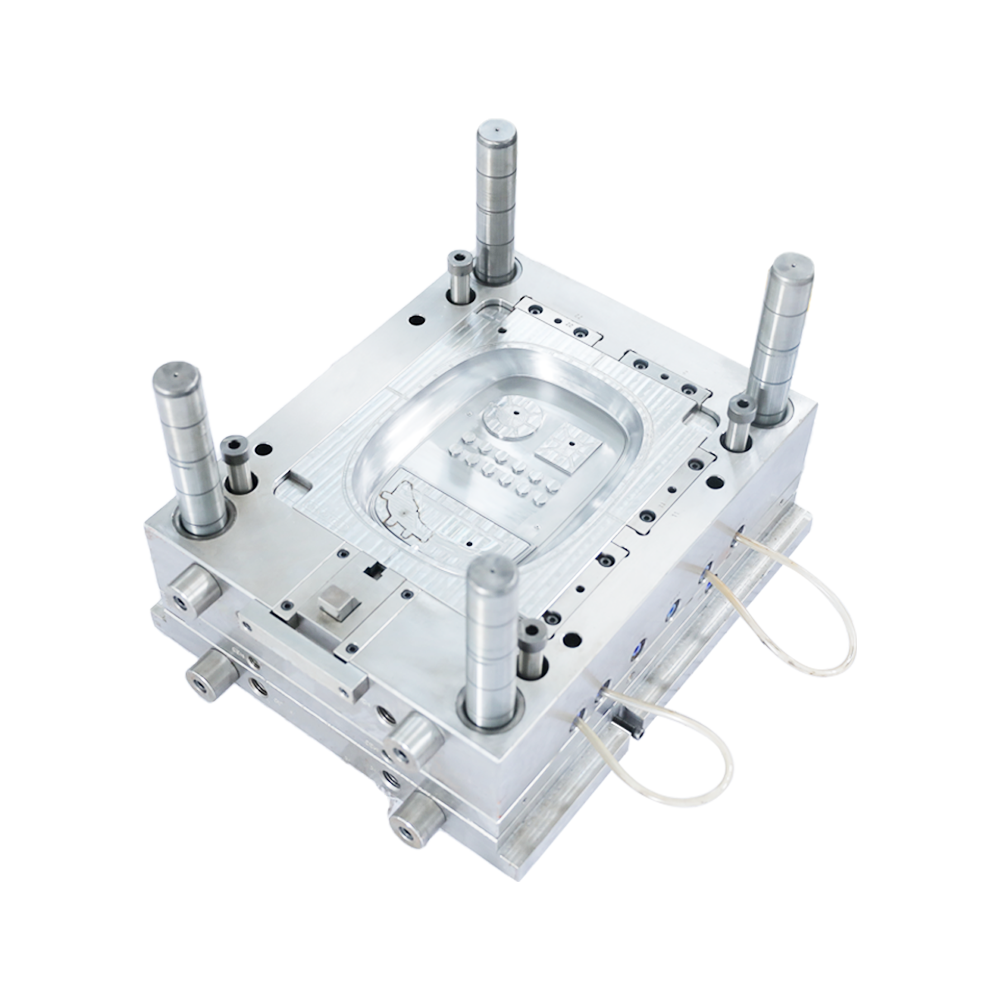

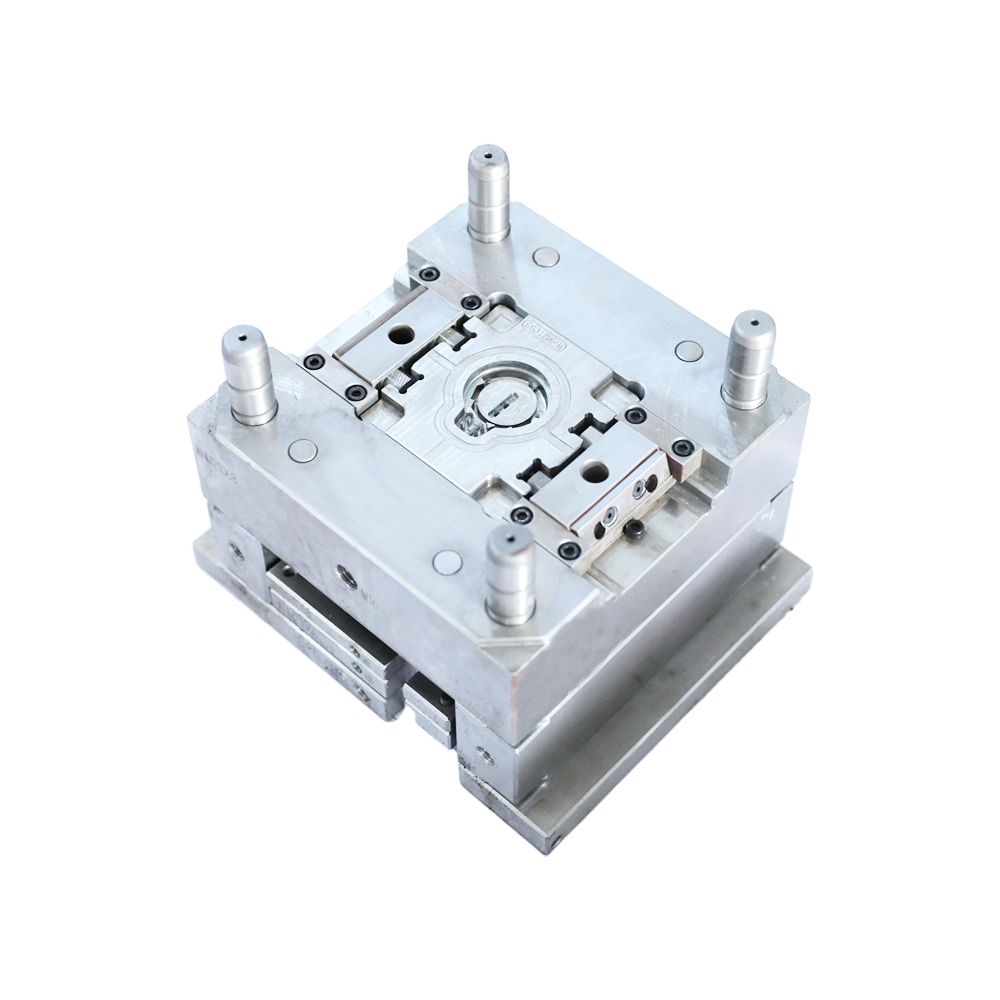

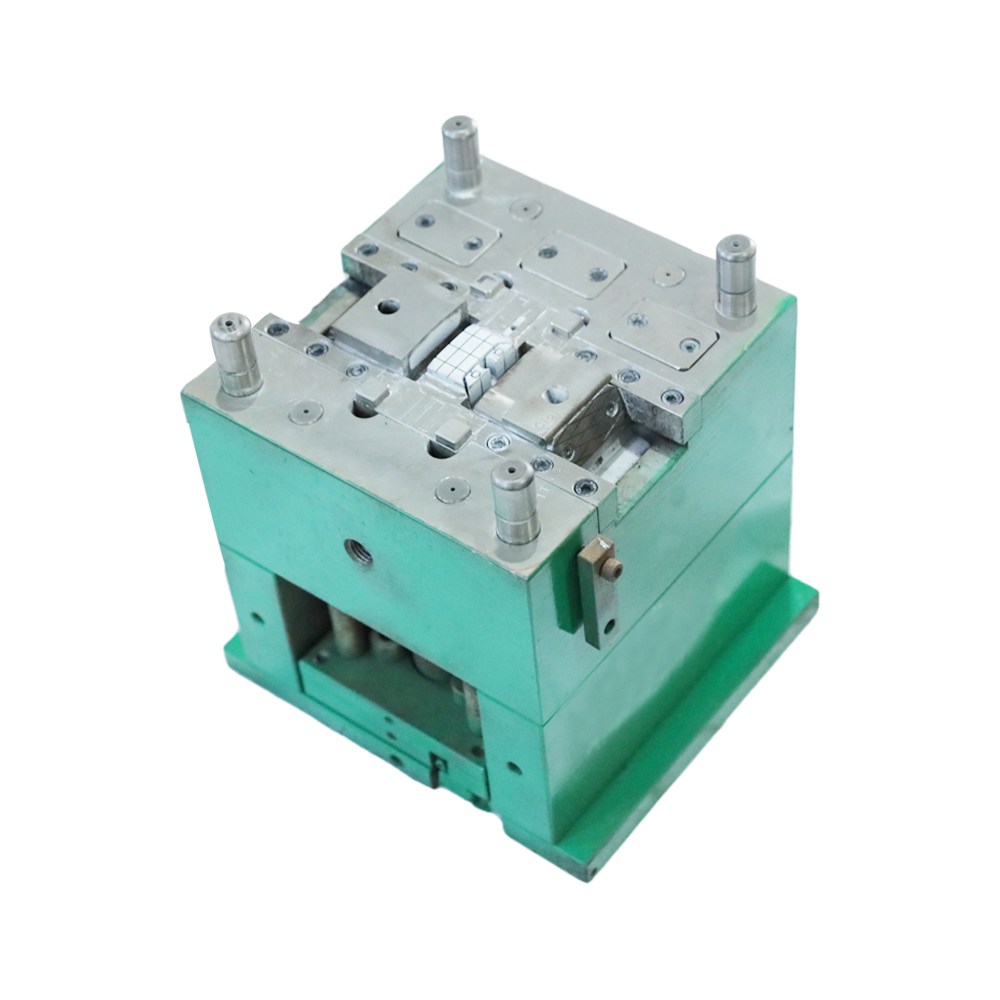

1: After the mold is used for a long time, the cutting edge must be ground. After grinding, the cutting edge surface must be demagnetized, and it must not be magnetic, otherwise it is easy to block the material. Mold users should record in detail, count their use, care (lubrication, cleaning, rust prevention) and damage, so as to find out which parts and components are damaged and the degree of wear, so as to provide information for finding and solving problems. As well as the molding process parameters of the mold and the materials used in the product, in order to shorten the test time of the mold and improve the production efficiency. The various properties of the mold should be tested under the normal operation of the injection molding machine and the mold, and the dimensions of the molded plastic parts should be measured. Through this information, the existing state of the mold can be determined, and the cavity, core, cooling system and parts can be found. According to the information provided by the plastic parts, the damage status of the mold and the maintenance measures can be judged.

2: Springs and other elastic parts are easily damaged during use, and usually break and deform. The method to take is to replace. During the replacement process, you must pay attention to the specifications and models of the springs. The specifications and models of the springs are confirmed by the three items of color, outer diameter and length, and can only be replaced if the three items are the same. The quality of the imported spring is better.

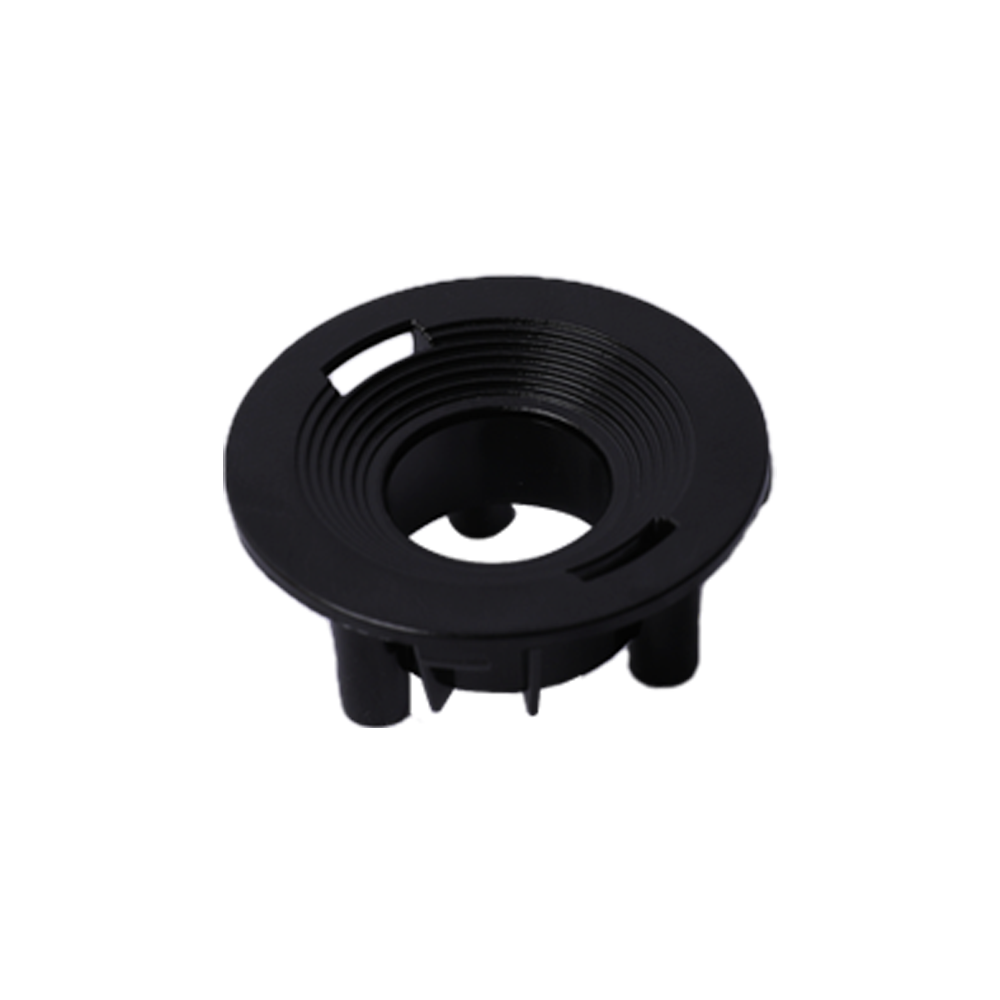

3: During the use of the mold, the punch is prone to breakage, bending and gnawing, and the punch sleeve is generally gnawed. Damaged punches and sleeves are generally replaced with parts of the same specification. The parameters of the punch mainly include working part size, installation part size, length size, etc.

4: Fasten the parts, check whether the fastening parts are loose or damaged, and the method is to find parts of the same specification for replacement.

5: Pressing parts such as pressing plate, excellent glue, etc., unloading parts such as stripping plate, pneumatic top material, etc. During maintenance, check the relationship between the parts and whether there is any damage, repair the damaged parts, check whether there is air leakage with the pneumatic jacking material, and take measures for the specific situation. If the trachea is damaged, replace it.

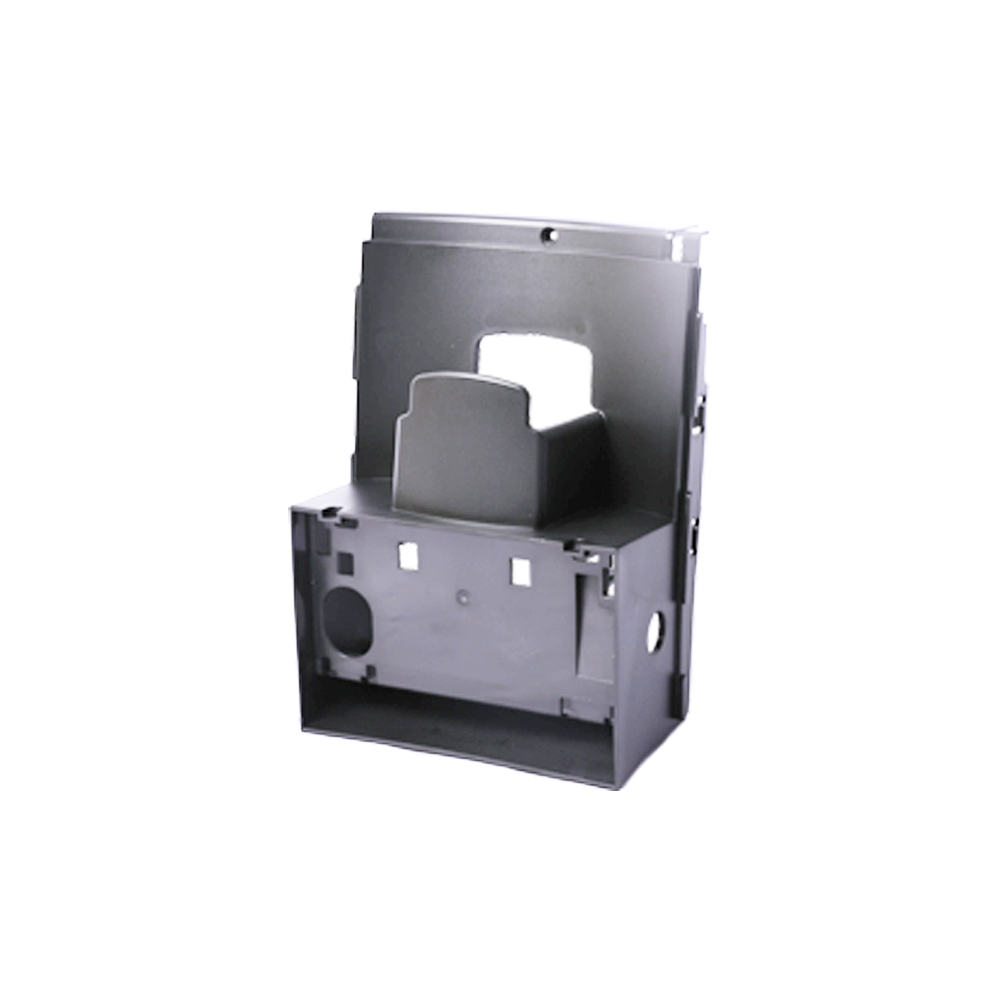

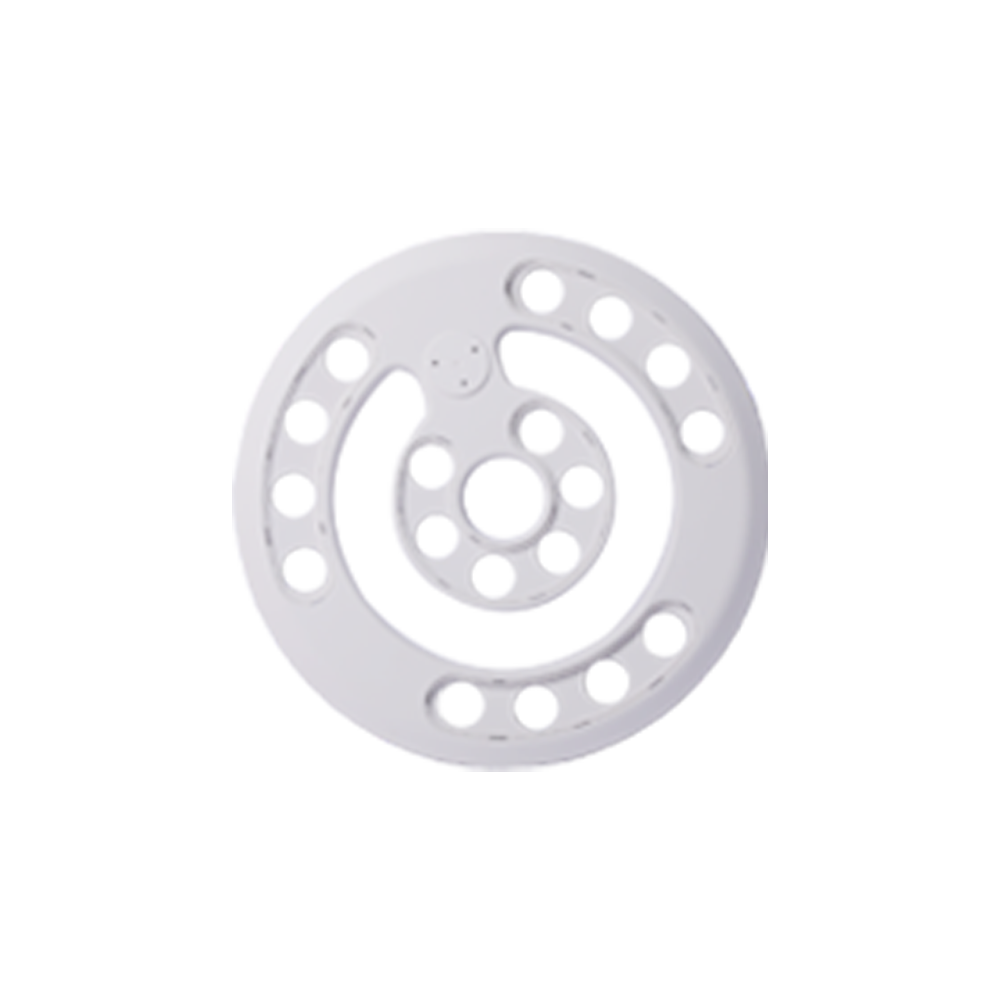

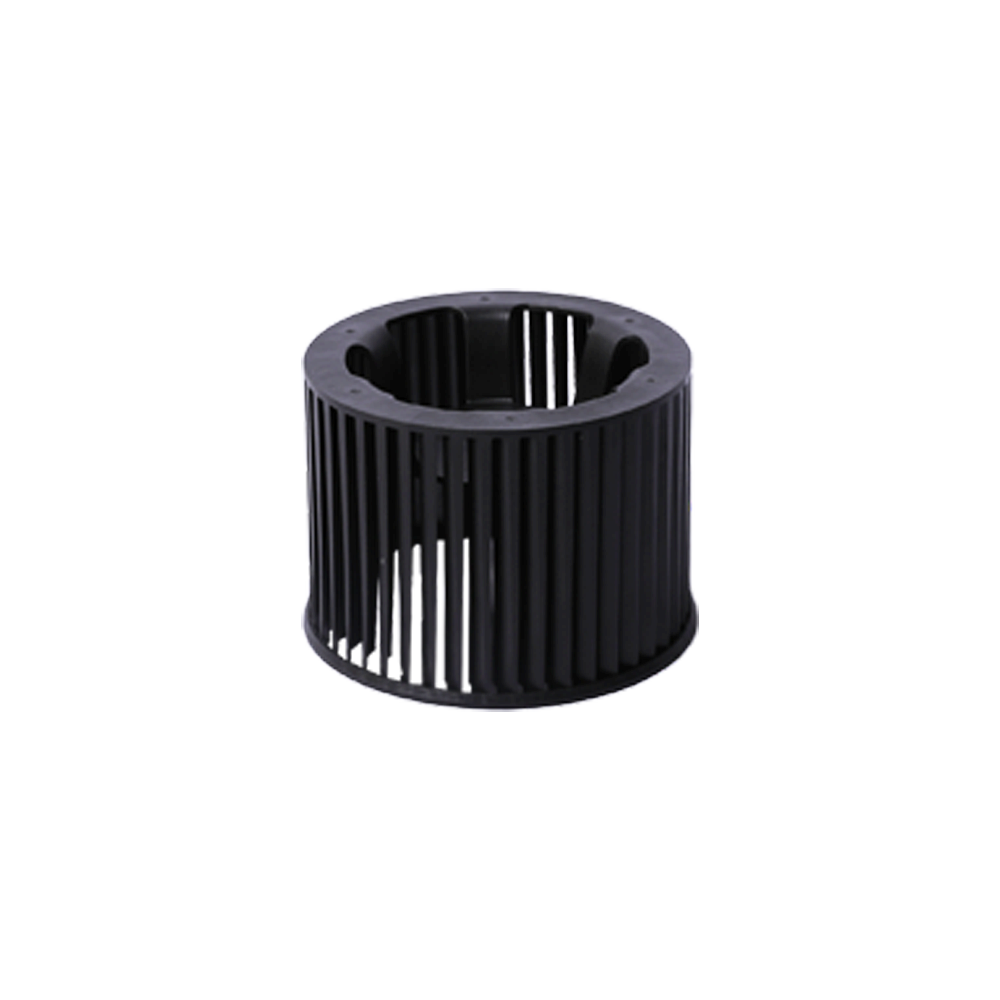

Suzhou Wellhong Electric Co., Ltd. is a professional manufacturer of precision molds , injection molding, assembling and silk-printing. Some Auto parts Mould are exported to Japan, Europe and the United States. We have the right to import and export the goods. We can develop and manufacture the moulds according to the needs of our customers. We pay attention to quality control, new project development, personnel training, team spirit. In recent years, we have established long-term business relationships with many well-known enterprises at home and abroad.

+86-15995701933

+86-15995701933 [email protected]

[email protected]- OEM Plastic Mould Manufacturers

��������

��������