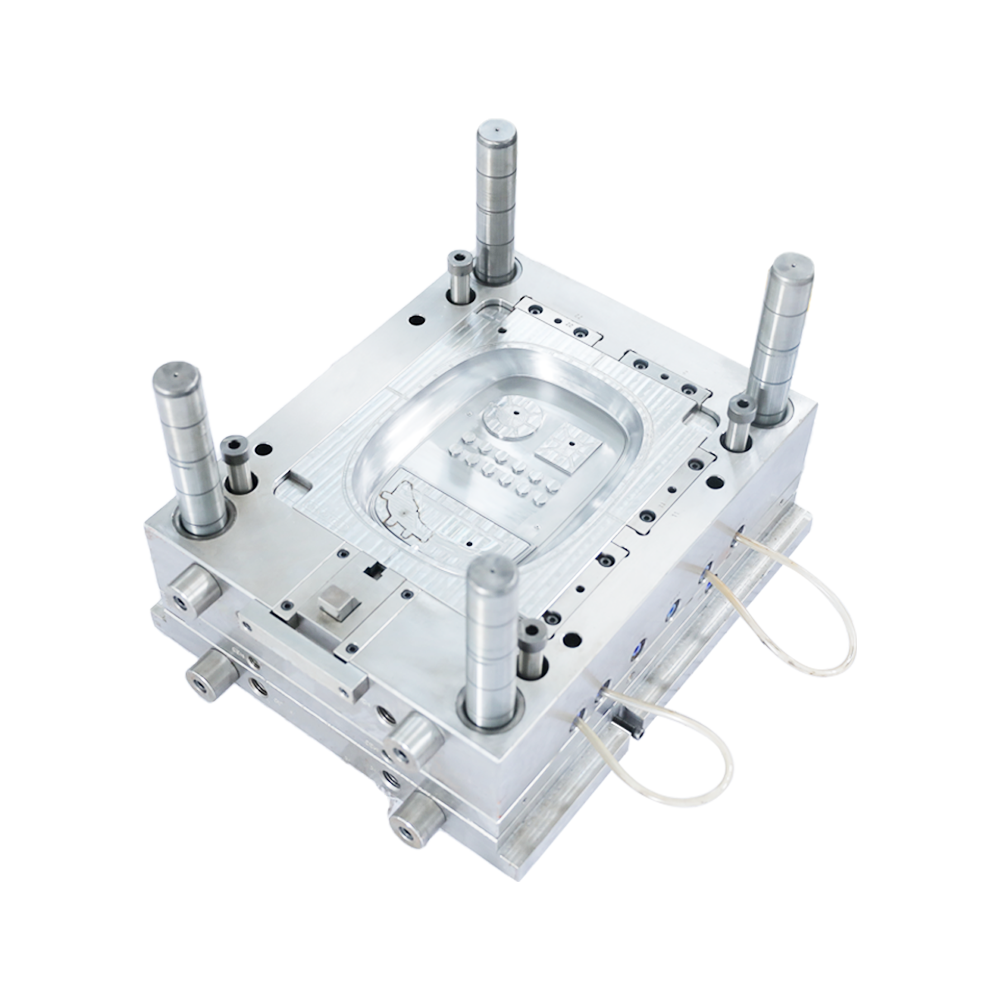

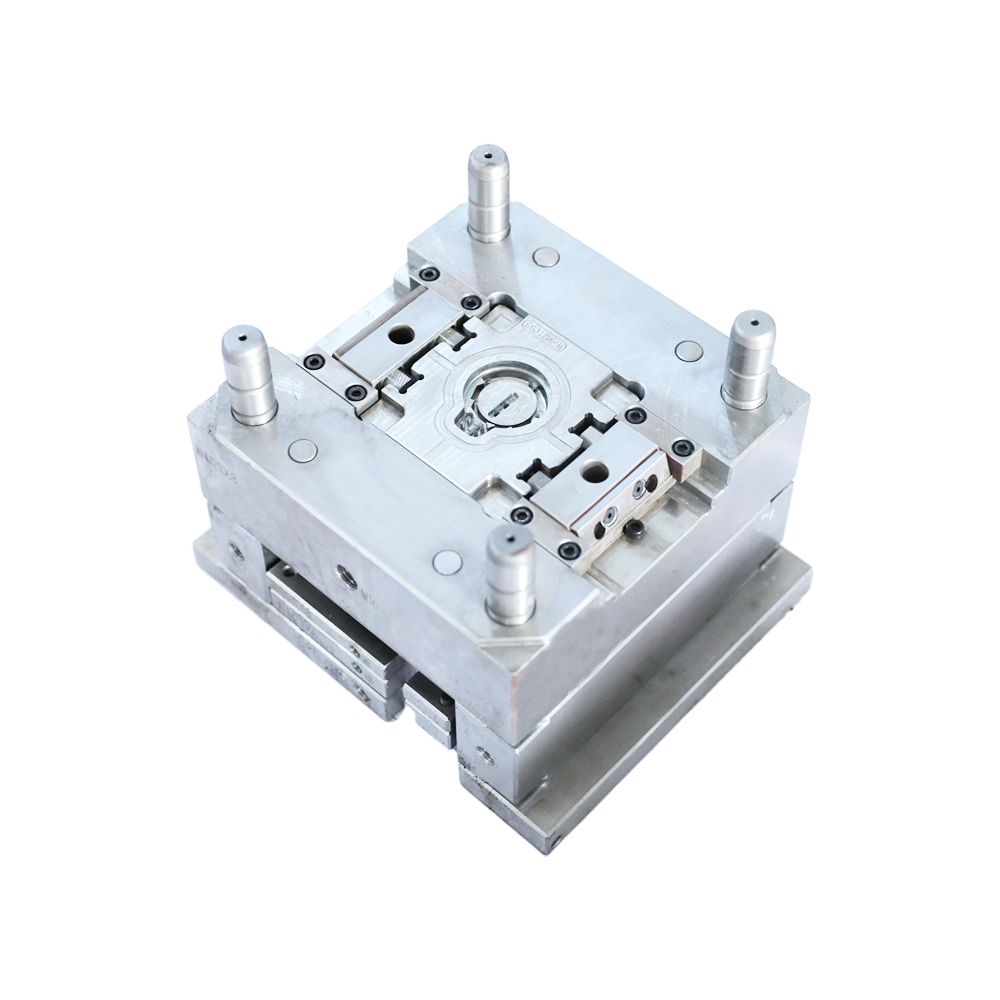

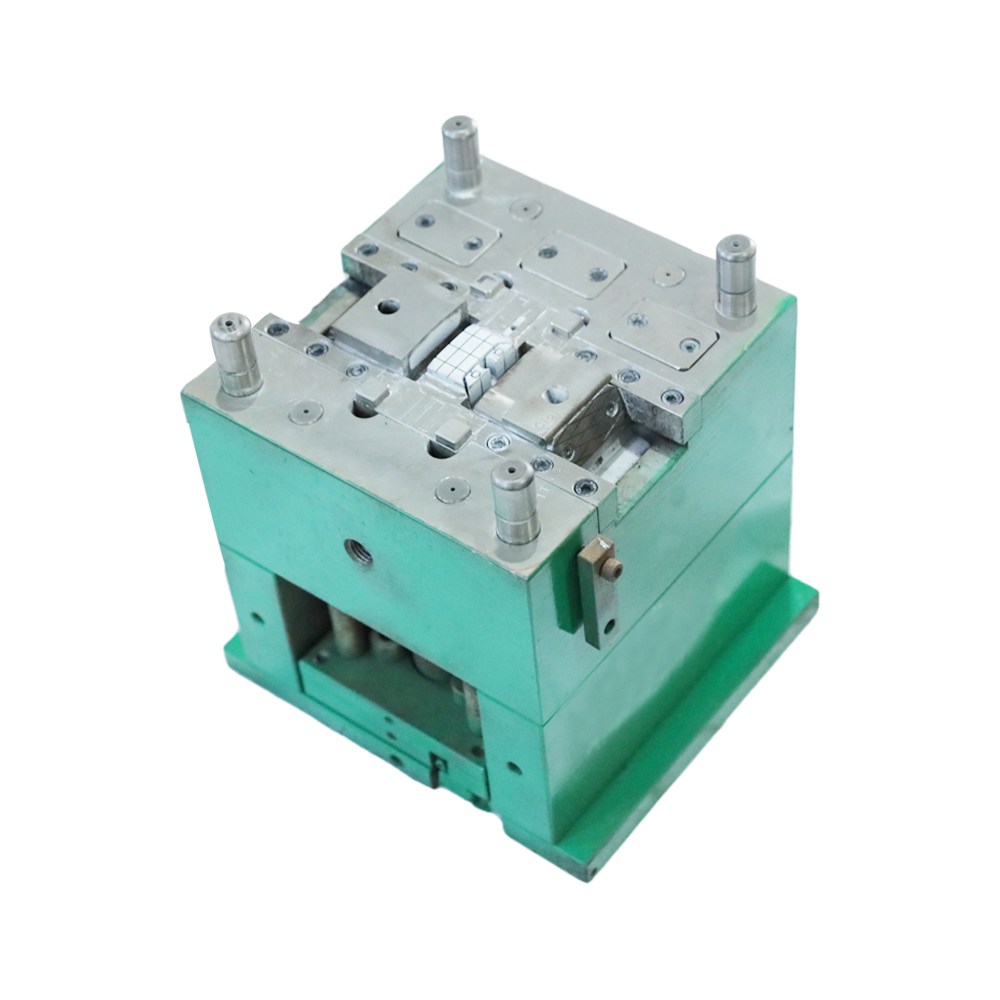

Inspection during mold making

The control of the raw materials of the mold is carried out from the following aspects:

1. Macro inspection

The chemical composition is decisive to ensure the performance of the steel, but the composition is qualified and cannot fully explain the performance of the steel. Due to the inhomogeneity of the internal structure and composition of the steel, the macro inspection supplements this deficiency to a large extent.

Macroscopic inspection can observe the crystallization of the steel, the failure of the continuity of the steel and the inhomogeneity of some components.

There are 8 common macro defects: segregation, porosity, inclusions, shrinkage cavities, bubbles, white spots, cracks, and folds.

2. Evaluation of annealing structure

The purpose of annealing is to reduce the hardness of the steel, facilitate machining, and also prepare the structure for subsequent heat treatment.

The annealed structure of carbon tool steel is evaluated according to the first-level rating chart of GB1298.

3. Carbide inhomogeneity

Cr12 type ledeburite steel contains a large amount of eutectic carbides in the structure, and the inhomogeneity of carbides has a very important influence on the performance, so the distribution of its carbides must be strictly controlled.

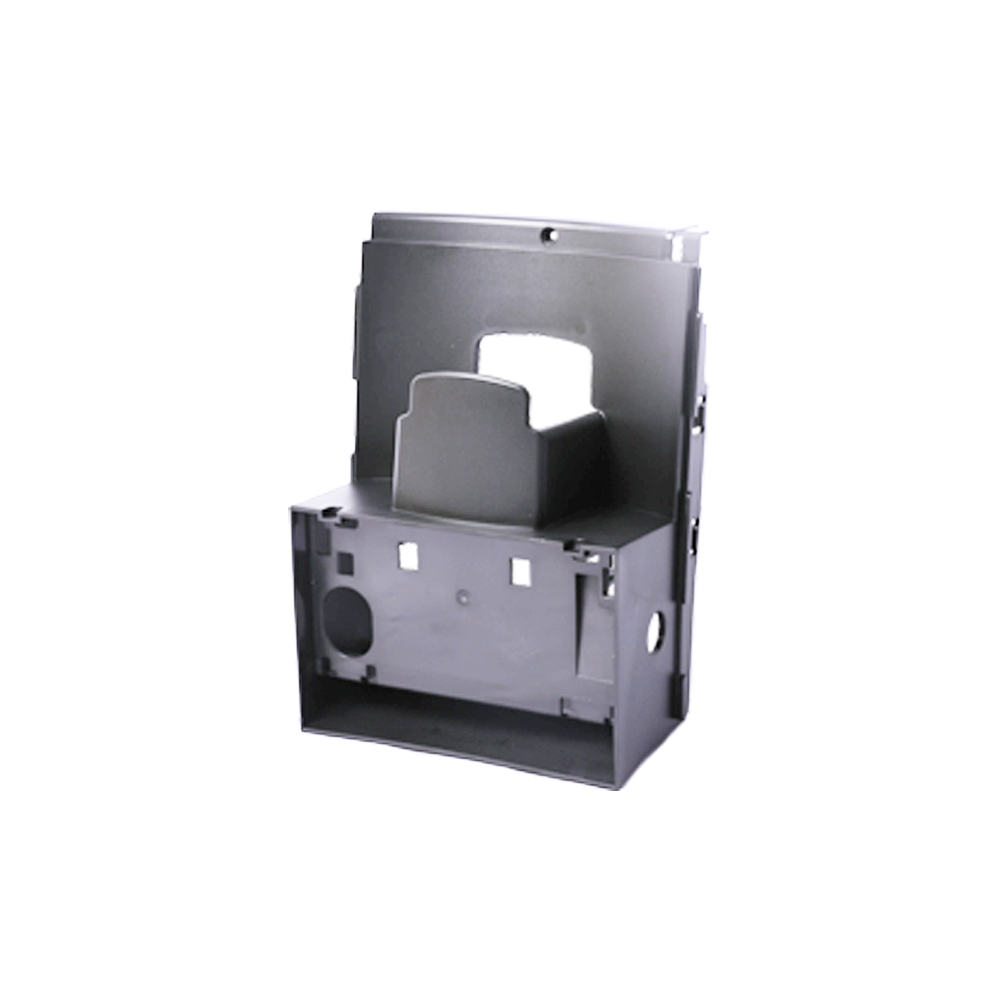

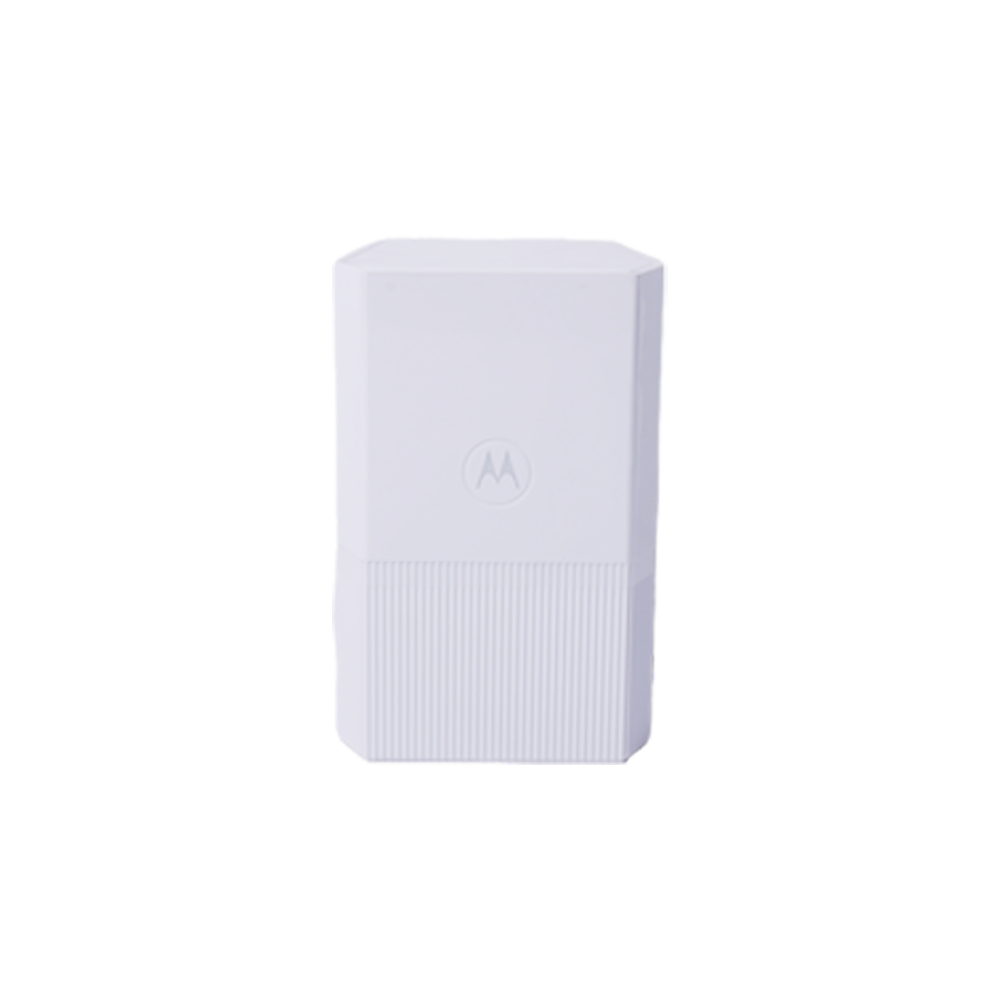

All in all, due to the cumbersome production objects of mold factories and workshops, and more or less single pieces and small batches, it brings certain difficulties to the formulation and management of mold production quotas. In addition, the production methods of each factory and workshop, The equipment and technical quality are not the same, so when setting the quota, it is necessary to find an appropriate method to formulate an advanced and reasonable working hour quota according to the actual situation of the factory and workshop, in order to improve labor productivity.

��������

��������