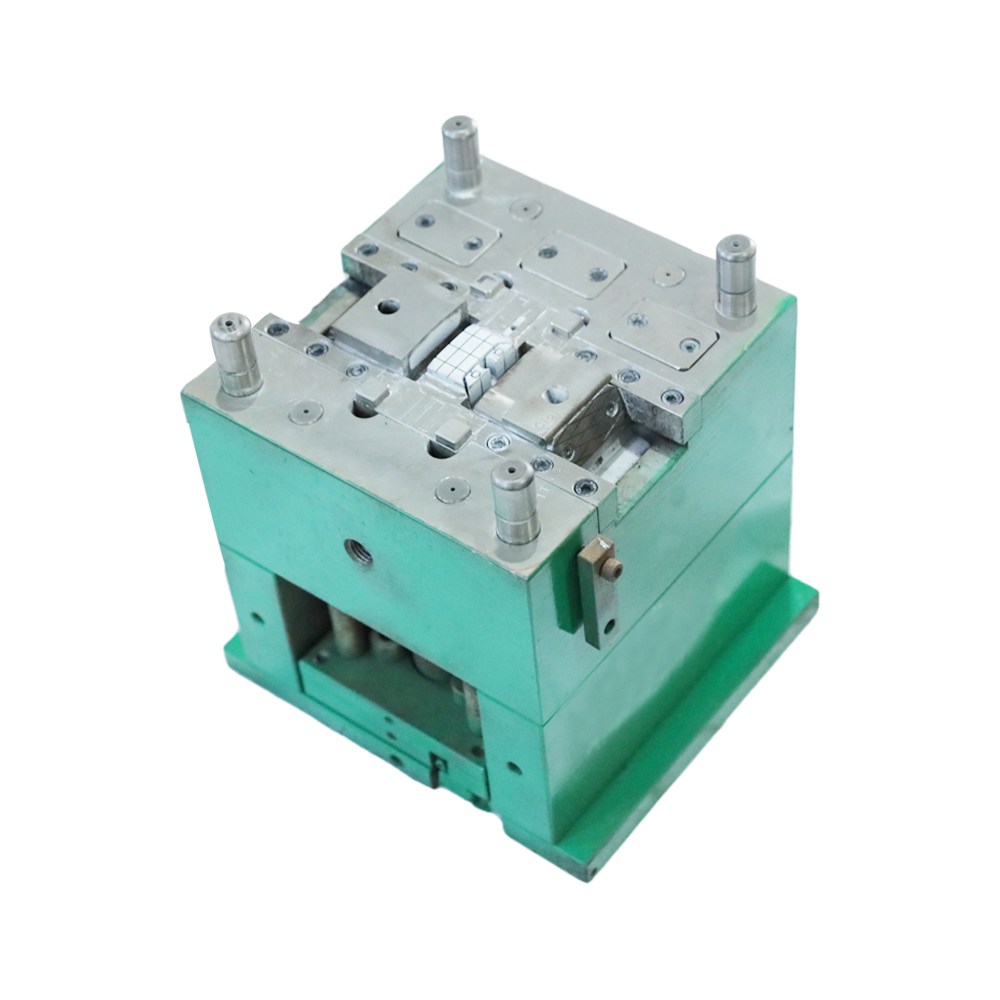

The material types of stamping dies include steel, cemented carbide, steel-bonded cemented carbide, zinc-based alloys, low melting point alloys, aluminum bronzes, polymer materials, etc.

At present, the materials of stamping dies are mainly steel, and the commonly used types are carbon tool steel, low alloy tool steel, high carbon and high chromium, medium carbon alloy steel, high speed steel, basic steel, cemented carbide, steel bonded cemented carbide, etc. .

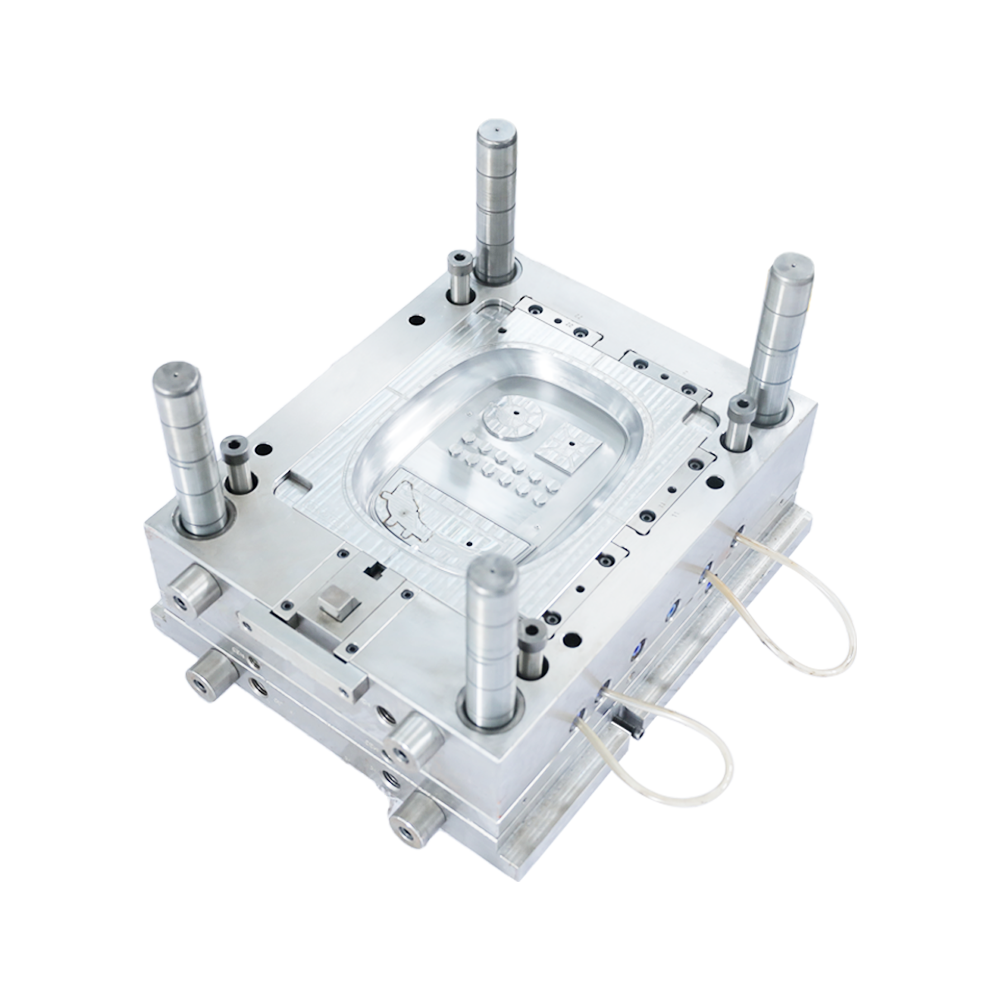

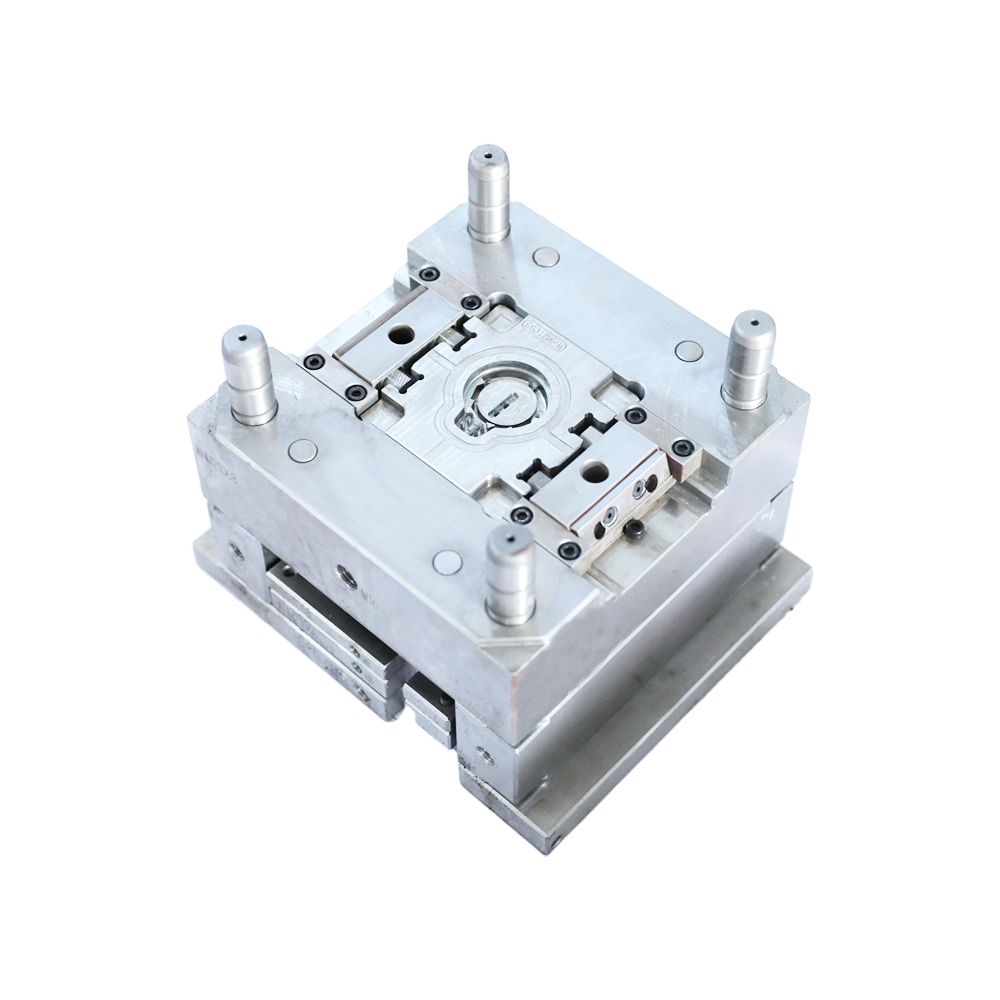

Features and advantages of stamping die:

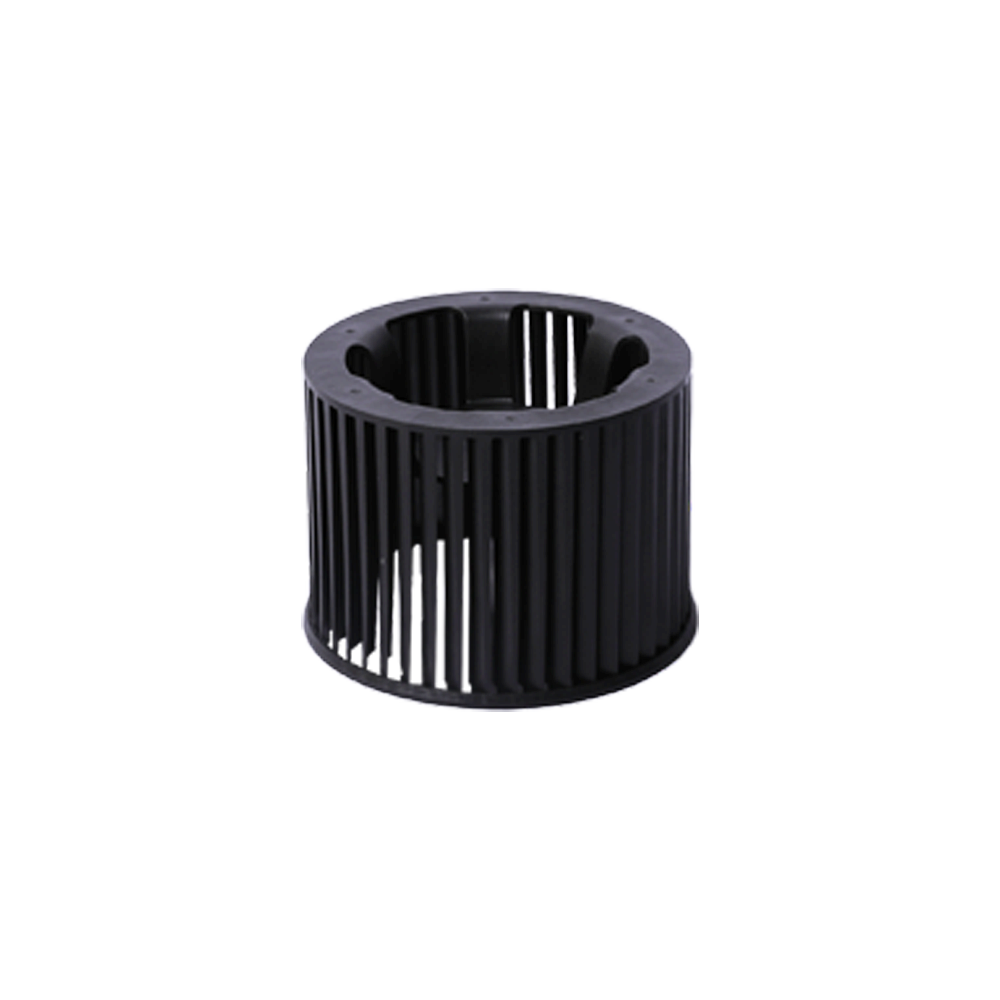

1. The number of parts completed by the stamping die per unit time is several times, even hundreds to thousands of times that of the general processing method. Moreover, the stamping process can use a combined processing method on a set of molds to further improve production efficiency.

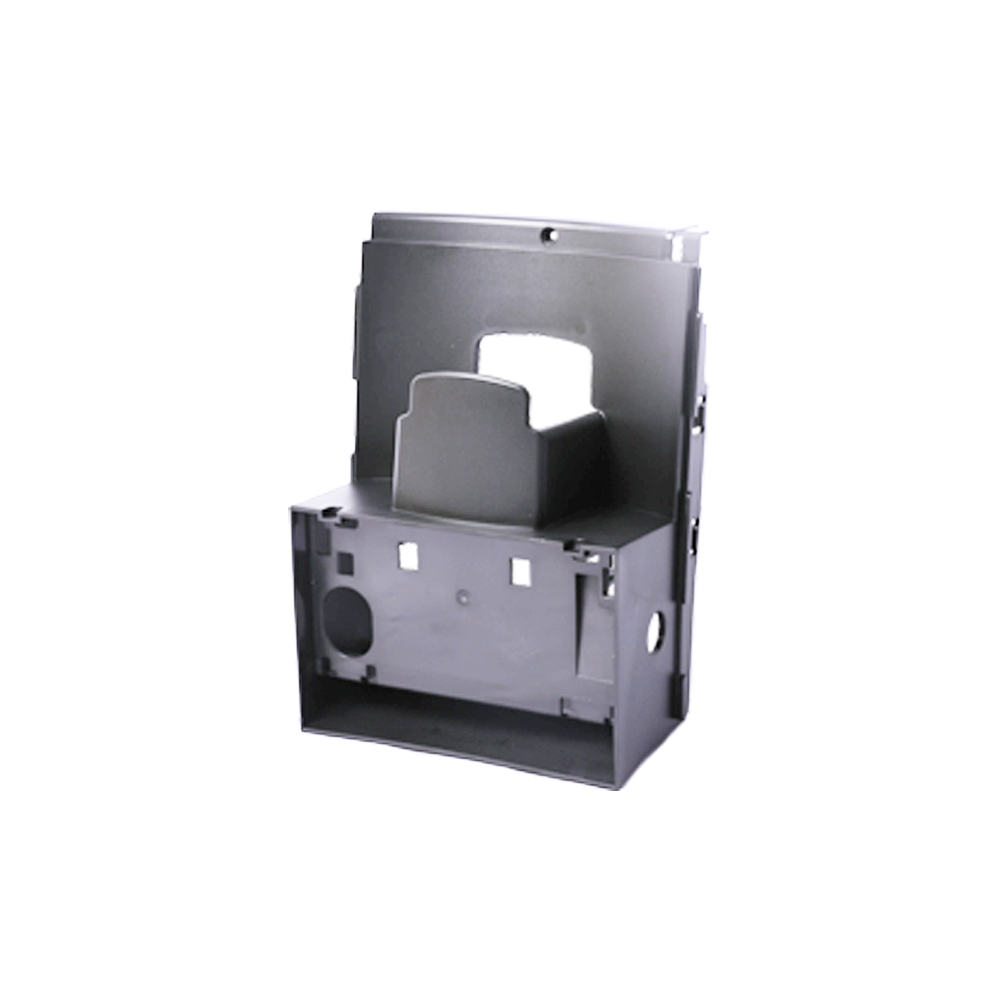

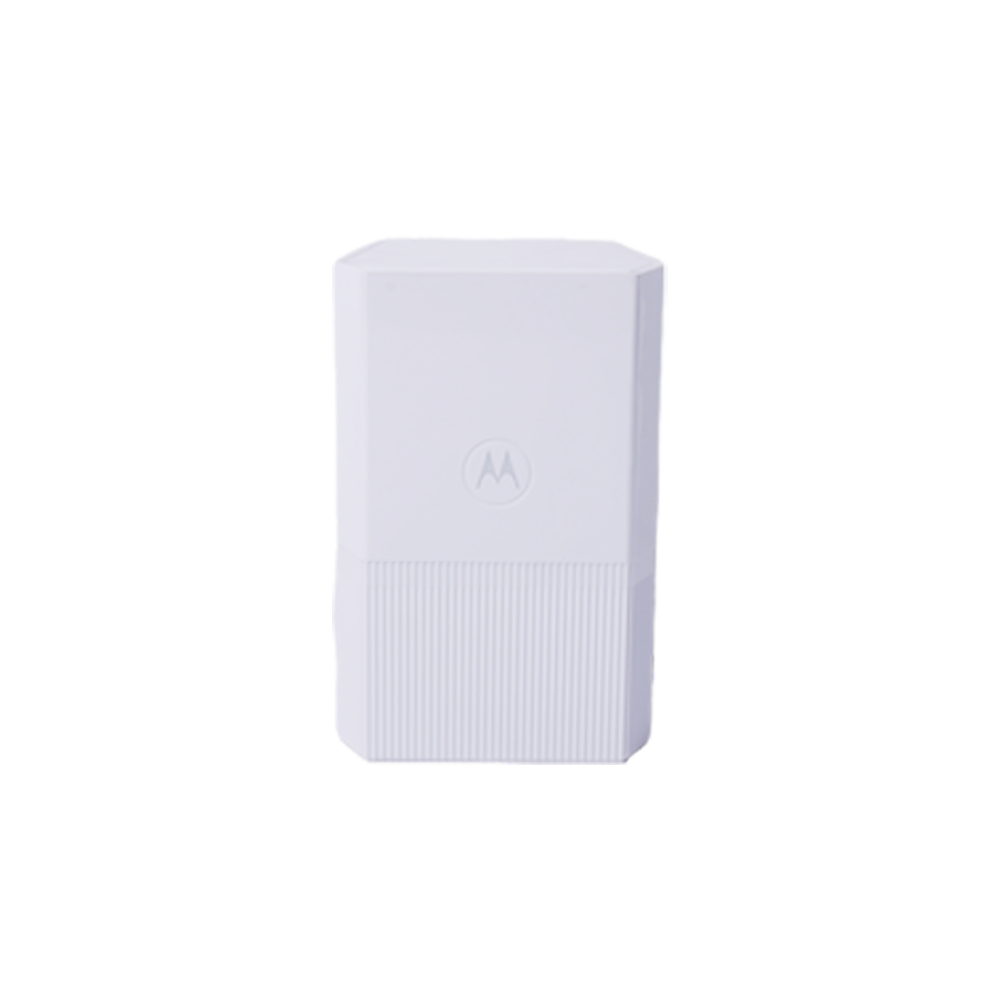

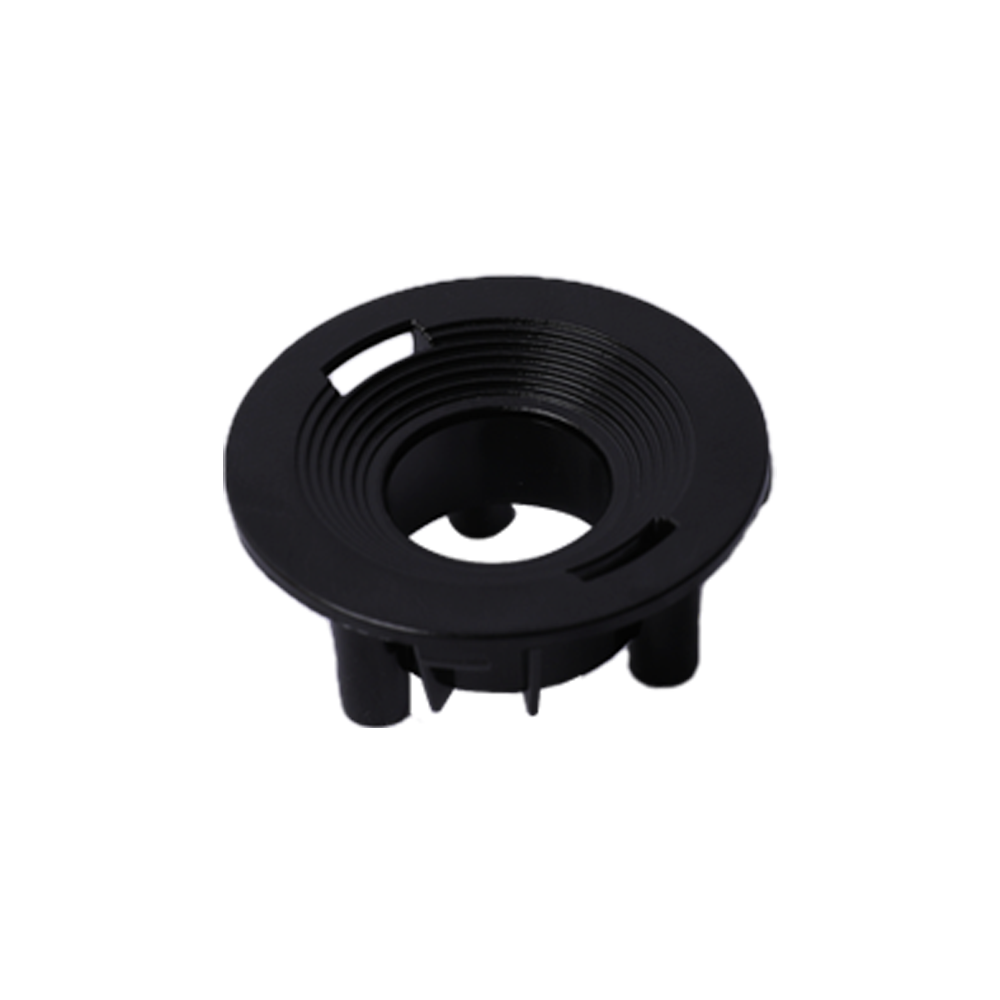

2. The products produced by the stamping die have the characteristics of stable quality, strong mechanical properties, compact structure, good interchangeability, good wear resistance, convenient maintenance and mass production.

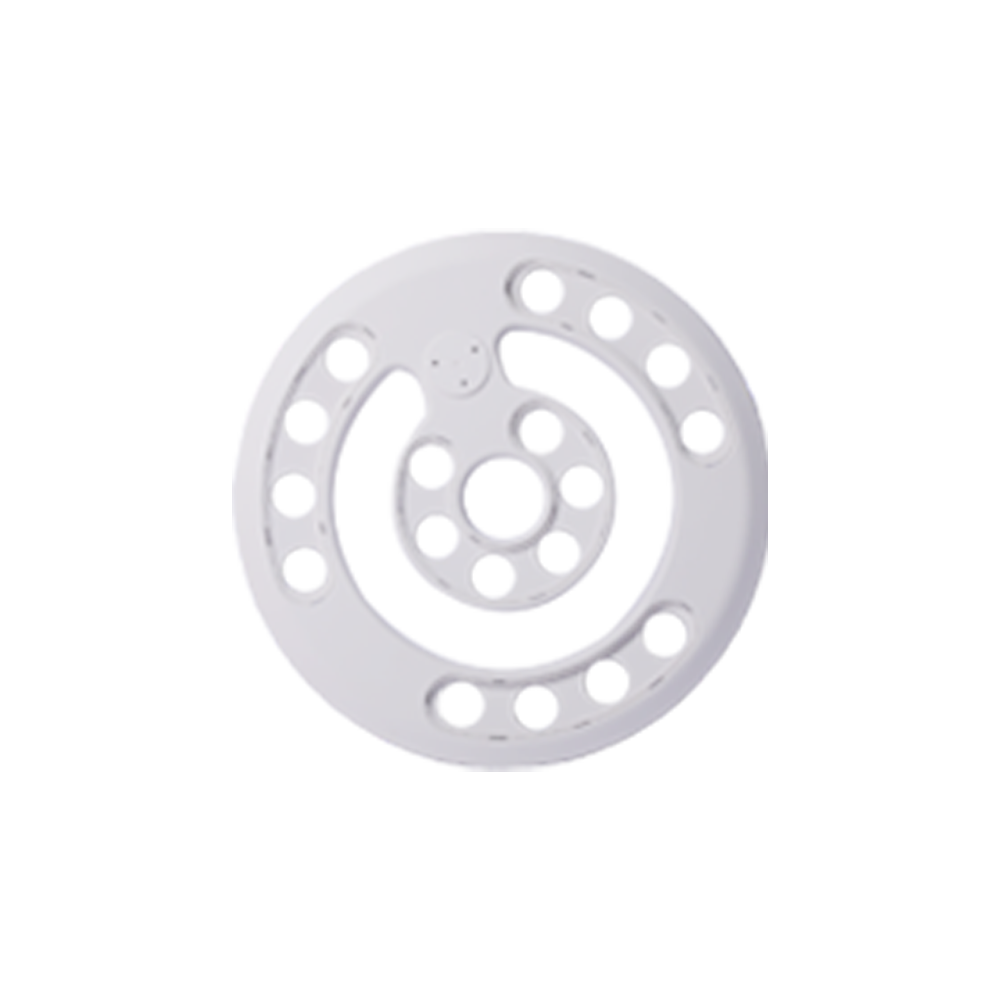

3. The material utilization rate of the stamping die is high, and a variety of layout methods can be used, such as cross, oblique, multi-row, mixing, nesting, etc., which can reduce the material cost of the product.

4. Usually, there is no need to heat the material during the stamping process, which not only saves energy, reduces the occupation of heating equipment and venues, but also avoids product surface oxidation, burns and deformation caused by heating.

5. Stamping dies are widely used and can solve operations that cannot or are difficult to complete by general processing methods, especially suitable for the processing of thin, soft, difficult and micro parts.

+86-15995701933

+86-15995701933 [email protected]

[email protected]- OEM Plastic Mould Manufacturers

��������

��������